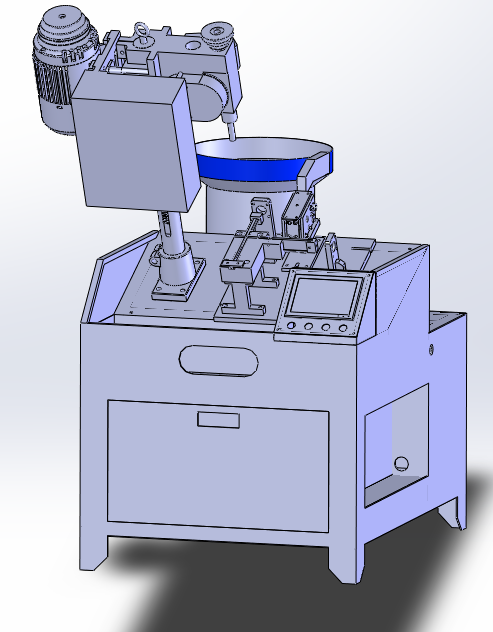

Armpro Slanting type autofeeding tapping Machine Characteristic:

- Tapping machine with Cutting TAP/forming TAP & through hole/blind hole are suitable.

- Fully automatic tapping processcan works all day long with heavy duty, One operator can easily operate several machines at the same time.

- 3. By using proper master pitch gears(change gears A and B pair), highly accurate thread can be tapped. It is easy and quick to change different size.

- The machine can be attached double spindle head and work efficiency can be more increased.

- It has safe device to monitor the feeding, torque, radial, and clamping to keep TAP’s long life and ensure safe working job.

- Tapping work governed by PLC

- Pre-work parts auto-checking and machine auto-stop if abnormal

- It can option to add inverter or use servo motor to control the spindle speed.

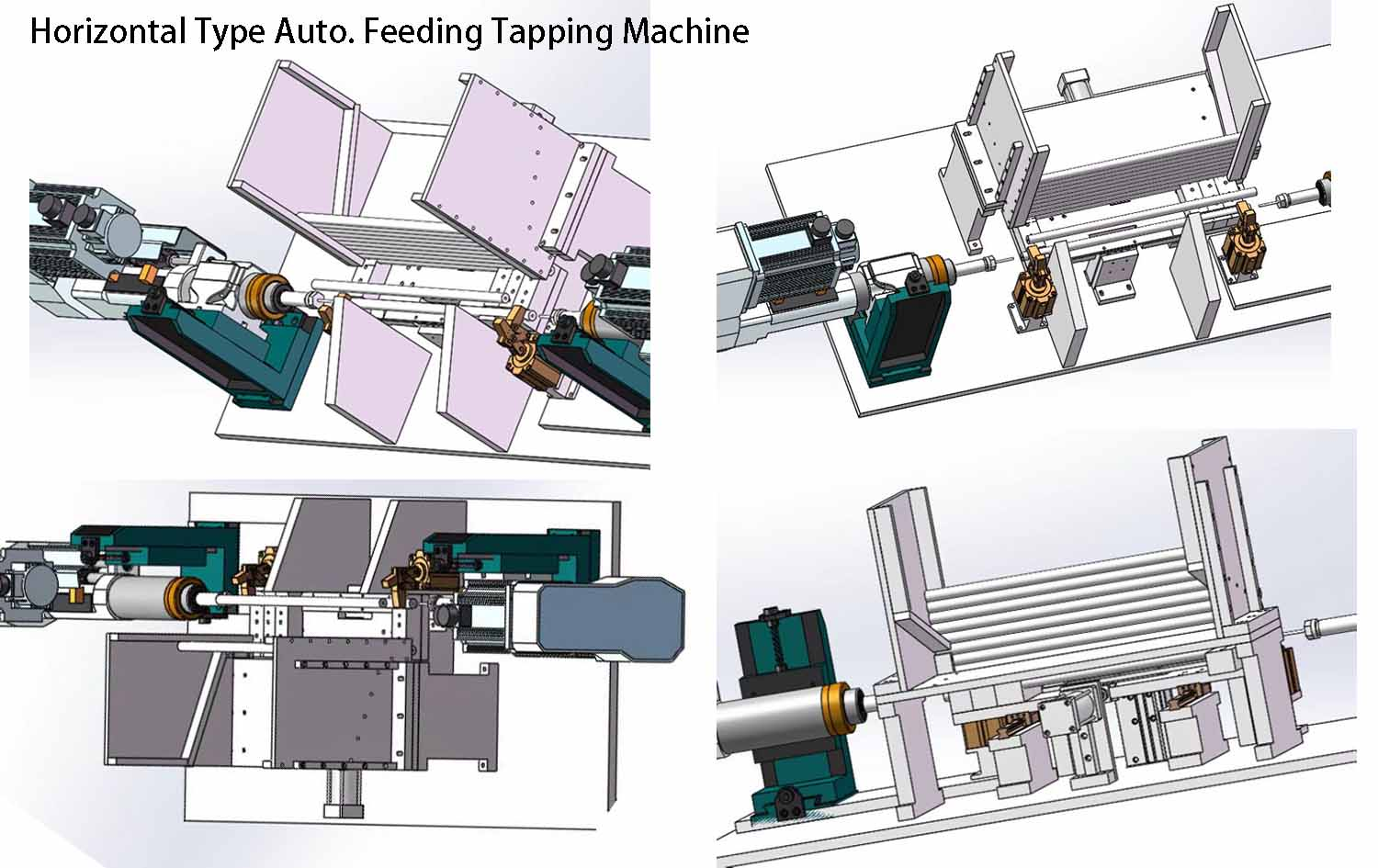

- we have also Horizontal Type Auto. Feeding Tapping Machine For thoses long parts can’t feed in vertical position.

- And considering safe working condition requirement,we have optional FULL COVER

| Slanting type autofeeding tapping Machine | |||

| Model | NT4508 | NT6516 | NT6532 |

| Tapping Capacity | M2-M10 | M3-M16 | M10-M32 |

| Column Diameter | 42mm | 70mm | 85mm |

| Spindle Travel | 45mm | 65mm | 85mm |

| Spindle Head Travel | 260mm | 300mm | 300mm |

| Spindle taper | B16 | MT2 | MT3 |

| Max Distance Spindle Nose to base | 350mm | 470mm | 450mm |

| Motor Power | 0.75kw 3phase | 1.5kw 3phase | 2.2kw 3phase |

| Voltage | 380v/415v | 380v/415v | 380v/415v |

| Spindle Rotation | 420/760/1340 rpm | 260/400/590 rpm | 80/150/280 rpm |

| Tapping production output | 15-20pcs/min

Up to actual application |

15-20pcs/min

Up to actual application |

10-15pcs/min

Up to actual application |

| Machine body size | 1000*1400*1800mm | 1000*1400*1800mm | 1000*1400*1800mm |

| Weight | 400kg | 580kg | 650kg |

Slanting type autofeeding tapping Machine

Slanting type single head autofeeding tapping Machine manily consistant of three parts: Gear pitch tapping machine, PLC control system, autofeeder with fixture.

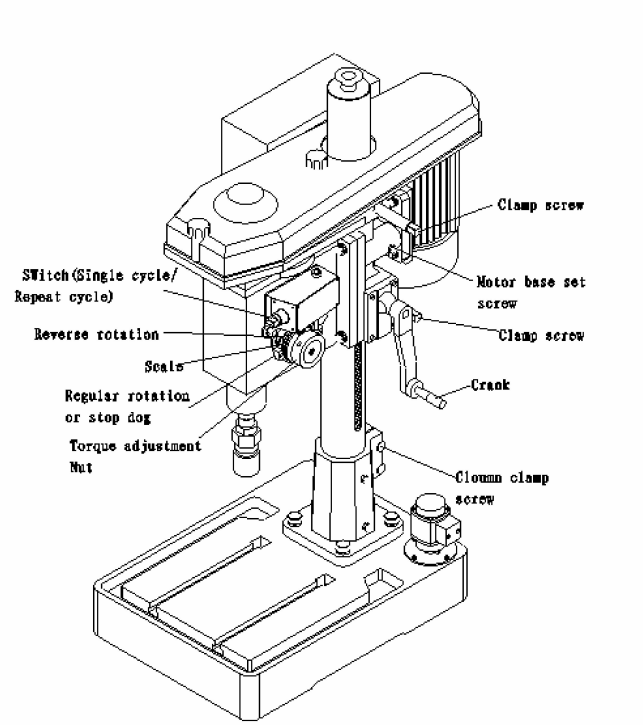

1.Gear pitch automatic tapping machine

We have various tapping machine model for different application, GP4508, GP6516, GP6532

Including Horizontal tapping machine and Vertical tapping machine for differ tapping solution.

Characters:

- Motor is particular designed with automtic control loop.Function options of blind holes,and reduce costs.

- Could be operated continuously,steady and durable.

- The tapping depth can easily be adjusted for high accuracy which is suitable for tapping blind hole parts.

- Tapping capacity can be easily adjusted by change gear

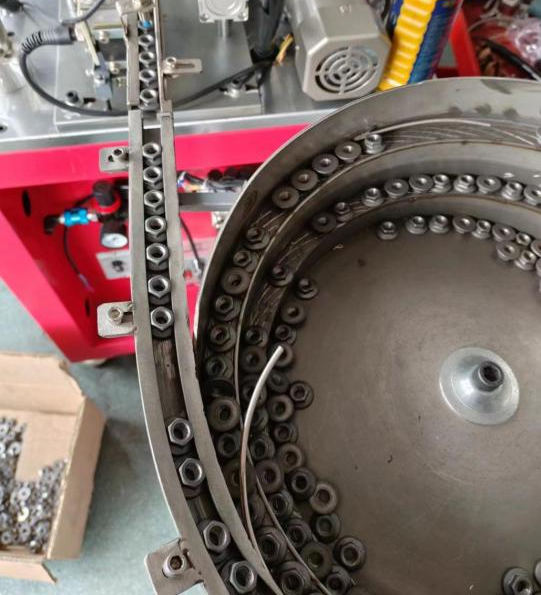

2.Vibratory Feeder Bowls

Armpro Multipurpose Bowl with Adjustable Tooling enables one feeding system to orient and feed a variety of screws, nuts, rivets, tapered parts and many others with a single unit.

An adjustable rail in the bowl’s discharge facilitates the orienting of headed parts like nuts, rivets and other fasteners with varying shank lengths and diameters.

Cylindrical parts, with a larger diameter close to one end versus the other, orient reliably in this bowl’s “hanging” style tooling.

Complete feeding systems include the tooled bowl, a base unit, and a vibratory feeder controller.

Reviews

There are no reviews yet.