Welcome to Visist Our Electric Tapping Machine Factory

Welcome customers from any country come to visit us, we can show you the electric tapping machine workshop, and show the Electric tapping machine inspection site before delivery.

The Buyer's Guide

Electric Tapping Machines:the Ultimate Buying Guide in 2026

Electric Tapping Machines are eminent in guarantee and quality inconvenience-free execution. These track down their various application in different designing ventures like Automobile Parts Manufacturer, Extruder Manufacturer and some more.

You can likewise benefit from self-made Electric Tapping arrangements according to their decisions. The machine embraces servo drive control, with insightful force assurance, rather than the conventional machine.

This guide will elevate your knowledge to the depth as all the related information will be shared. Let’s begin it.

1.What is electric tapping machine?

Electric Tapping Machine

An electric tapping machine is an efficient gadget used for making thread holes in metal items by using electric power provided by the central servo motor. It has a control panel having different sorts of functionalities on it which makes the interaction with the machine for the worker easy.

Different combination of clutches provides ease for the tapping machine to make holes easily without facing any resistance force that might slow down the tapping process.

In electric tapping the process of making thread holes is mainly depend upon the electric power because the amount of electric power defines the work productivity of a tap edge to make holes.

A tap going into the hole makes a thread shaped screw hold with the help of sharp edges that are present on the top of a tap.

2.What are the types of the electric tapping machine?

Depending upon the structure and working functionality there are different kinds of electric tapping machines that are available for you to work with.

Here is the list of some electric tapping machines which most of the people use for threading holes in metal plates.

- Arm Type Electric Tapping Machine.

- Horizontal Tapping Machine.

- CNC Electric Tapping Machine.

- Portable Electric Tapping Machine with.

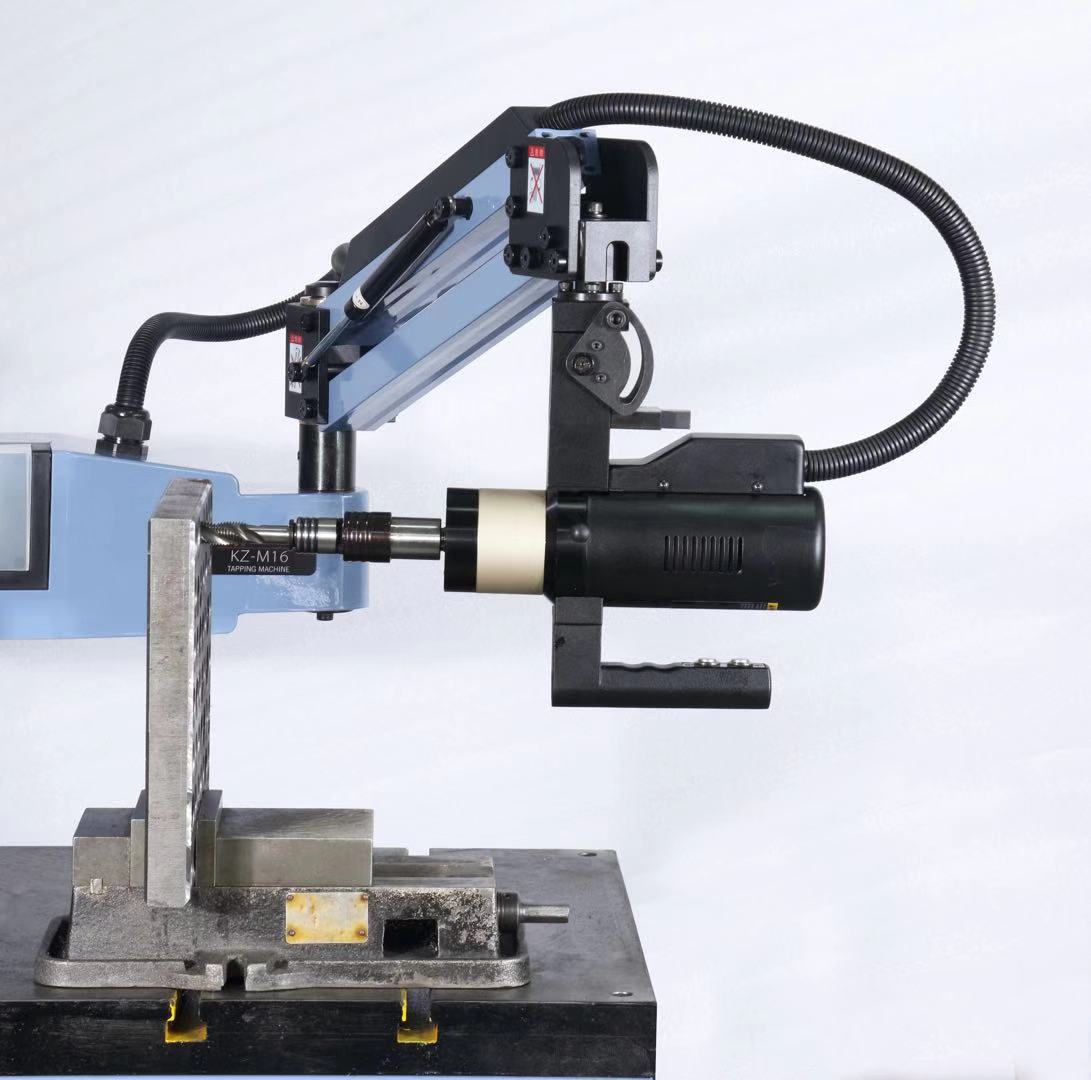

- Arm type Electric Tapping Machine

Basically, arm type electric tapping machines are highly depend upon the work functionality and power of their arm because an arm in this machine defines the productivity of the machine along with the RPM speed of the tap.

Most of these tapping machines are used to work with large size materials because it is not an easy task to drill different materials with a small size arm tapping machine.

Well, the arm type electric tapping machine has some sub-categories depending upon the structure and flexibility of the arm.

Horizontal Electric Tapping Machine

In a horizontal electric tapping machine there is a metal bed or some of the machines have only metal rod on both sides of the bed to hold the material high accuracy tapping. A stroke system for tapping purpose is very precise in this machine.

A limit switch present on the panel of this horizontal electric tapping machine used for reversing the tapping process to give accuracy and precision at the same time. This tapping machine is highly recommended for working with blinding tapping holes.

You can easily use this machine for inner threading with the help of tapping strokes, nevertheless, it is also useful for outer tapping process.

CNC Electric Tapping Machine

This tapping machine is made for different kinds of tapping & threading materials like metal pipes to make the end product in a good manner. This tapping machine also works through an arm which can easily enter the tapping strokes into the holes automatically.

The main body of this machine is large as compared to other electric tapping machines because it holds a larger size motor to provide power to the drilling strokes for tapping purpose.

The touch screen panel in this machine helps you to control the speed, width and pitch of the material for accurate tapping and threading.

Portable/Handheld Electric Tapping Machine

A tapping machine which can be easily handled by a single person by holding it into the hands and making taps or threads on different kinds of materials like metal plates.

You can easily change the tapping head of the machine for the kind of tapping you want because it is easy for you to replace the kind of drill head you want according to your product.

Some of these machines have batteries in them and some of them worked through electrical motor with a direct source of electricity.

3.What are the Applications of the electric tapping machine?

There are different applications of electric tapping machine and there are some powerful industries in which a tapping machine plays a vital role for development of different products.

Ancillary Industry

There are different small parts that are prepared with the help of a tapping machine and these small parts are then used inside the machine for making complete equipment. Some small parts like gears, assemblies used in the engine, and intercedes.

Most of the ancillary industry is used for auto parts to make some powerful tools that one can use easily for high accuracy tapping.

Valves Industry

In this industry there are many kinds of valves materials that are prepared with the help of electric tapping machine. Most of the equipment that we use in our daily life they hold a valve part to give nuclear or electric power to the engine of the specific machine like a plug is used in vehicle industry to provide a spark with the combination of gas engine and oil.

Not only that, some valve industries also use electric tapping machine for making different designs on gates, diaphragm is also prepared in this industry, metal balls used in different machines and also used for making globe butterflies.

Automobile Industr

Electric Tapping Machine

In automobile industry you can utilize electric tapping machine for making threads inside and outside of a metal element like a wheel is based on metal rim and different rims have different designs on them but a nut thread which is used for tightening the wheel uses the same type of tapping and this is done with the help of tapping machine.

Automobile industry uses the tapping machine according to the drilling holes because if the drilling holes are larger in size they will require large size tapping strokes.

Steel Rolling Plant

If you want to work with different steel based materials to prepare steel tapped items then electric tapping machine is also very useful in this purpose. Most of the threading and tap holes are prepared with this machine in steel based items because it is unique and highly recommended by the engineers for precise and accurate tapping.

Some steel items like a motor body needs threading holes in it and for this purpose a tapping machine is very precise with its working capability and greater productivity with less time consumption.

There are also many more industries in which tapping machine is being used highly for better product and the growth of this machines usage is increasing rapidly because of ease in working and less effort is required for this.

4.What are the advantages of electric tapping machine?

Electric Tapping Machine

There are a lot of advantages that you can get if you work with tapping machine instead of other machines like threading machine that are used almost for the same purpose.

- It is very useful for making threads on different rigid metal items like you can use this machine for threading purpose if you find it difficult to work with threading machine.

- One of the best advantages that you can get while working with the electric tapping machine is the top speed of this machine which is insane.

- When a tap moves with a high speed it will not demolish the natural surface of the material instead it will make precise threading in the holes.

- A tap head of a tapping machine is very rigid which will not be easily broken when you work with rigid metal items and on the other hand top speed of the tap strokes will help to achieve the required product.

- It has the ability to protect the product from overloading with the control over torque rate and arbitrary mobility of the tap head.

- It will require less labor to operate the machine because most of the functions are controlled by the machine with less electric power consumption.

- Going through the rigid items and breaking the metal lath is not easy but an electric tapping machine can easily do this work with top notch speed and accurate quality.

These are the top advantages of electric tapping machine which can help you to overcome what you are looking for by making sure that you can find the best machine to do this type of work.

5.Are there any disadvantages of the electric tapping machine?

There are some points or you can say steps where you need some extra time and extra effort to make to work with the electric tapping machine and we call them disadvantages.

- First and foremost, you may require to thread a hole according to the size of that hole and for this purpose you need to change the size of tap that you are using.

- On the other hand, you need to change the different tools of tapping machine to work with different type of hole which will ultimately affect the time cycle and production speed as well.

People say that these are the advantages that you may have while working with an electric tapping machine. Instead, these are some extra steps that you need to perform while working with the machine.

6.What is the different component of an electric tapping machine?

Every electric machine have some working parts to complete the structure of a machine and electric tapping machine also based on some working components to complete the structure and design of the machine.

Here is the list of some basic and general parts of the electric tapping machine.

Electric Spindle for Tapping

Most of the spindles are used to hold the main working head of the machine and in this machine spindle holds the drilling tap which to make the threading hole for tapping purpose.

Spindle is covered in a metal sleeve which helps to revolve the drill around its axis in the direction of a tapping material. Sleeves made the movement easy for the drill machine with less effect on the tapping.

Parallel Arm

Different parts of Electric Tapping Machine

This part of the machine plays an important role both in structure and also in working capability of the machine because without a holding arm it is very hard to work with large size and maximum amount of products at the same time.

Some of the electric tapping machines do not have any arm based tapping process but most of these do work on an arm system. Arm in an electric tapping machine is made with small parts and hold different components like air pressure pipe, tapping drill and metal pipe for stability which is called slanted arm used for controlling level of depth according to the type of hole which the tapping machine is using.

High Power Servo Motor

A motor which provides power to the electric tapping process is very powerful and create enough energy for tapping purpose. Every working part in the machine gets the energy from this motor to work along the machine.

Motor in an electric tapping machine works as a powerhouse to run different electric parts of the machine.

Mounting Table

This part in this machine is very important to set the arm system of the machine because it holds the arm with it working as a base on a table connected strongly. With the help of his component you can select the movement ease of the arm which is based on the mounting table.

A fixed wrench is used on the mounting table to connect the arm of the machine with its base for tapping purpose. A magnetic lifting chuck is also connected to this mounting table which works as a power vein to hold the am in upward direction by providing a lift.

Tapping Adapter

Tapping Chuck/adaptors

A tapping adapter is basically tapping chucks that are used for tapping purpose. Every type of product is fixed with the help of this machine and then the tapping starts from the fixed central position where you will not see any moment.

Every tapping tool is fixed in the chucks for making sure that the safety of your product is dealt with properly without any damage rate.

Cart or Working Table

This part mostly consists on the horizontal electric tapping machine where you set a tapping product on the table or cart to fix the movement of the product first and then the tapping is done.

Normally, the weight of the cart is like 200Kg with having 800 x 800 x 900 mm LWH.

These are the working components of the tapping machine which makes a complete tapping machine.

7.How does a tapping machine work?

Electric Tapping Machine

The working of an electric tapping machine is very simple and accurate as compared to other machines because the structure of this machine provides ease in working with it and it is much safe to do the tapping on hard rigid metal with any extra effort.

Step-1

A tapping machine works on the duplex sort of metal process where a metal screw is used for tapping holes on a metal item so it is fastened process based on two metal items. You can make a threading hole with the help of this machine to make the tapping process easy and it helps you to save your time by doing all the hard work automatically with minimum use of labor.

First in the tapping process a servo motor starts and gets into the rhythm while contacting with other parts of the machine.

Step-2

When every part of the machine gets into the working motion then a tapping product is set on the cart or table of the tapping machine having holes in it or may be without any holes only if you have that functionality as well along with tapping. Thread holes are made on this product for tapping purpose.

Step-3

Tapping chucks are used for tapping threads in the holes and a small drill is hold on the arm of the machine to make the working easy. The movement of the arm is performed according to the type of product which you are using you can just easily move the arm in downward direction or may be towards the rare because it is flexible enough.

Step-4

A complete mass production can be done with the tapping machine because you can perform different sorts of threading and tapping process at the same time.

The technical ability of this machine to work with different materials is very high and you can easily work with the machine having basic knowledge about the working principle because your material or product will remain safe and will not get any damage as the safety requirements are measured properly.

This is the working process of an electric tapping machine that you need to know if you want to work with this machine. A user guide will be provided to you for ease in working and interacting with the machine.

8.How electric tapping machine is useful for different engineering field?

Electrical Tapping Machine

Different engineering fields utilize this machine for their better working and to develop a fine product with less error rate.

In civil engineering different kind of holes are threaded on the floor or on the walls and this is done with different kinds of tapping chucks which are present on the drill.

In different engineering fields like mechanical or civil there are three basic types of electric tapping machine that one can use according to the type of product that you want to work with and these machines are.

- Two Fluted Tapping machine.

- Three Fluted Tapping machine.

- Four Fluted Tapping machine.

The only difference between these machines is their work ratio according to the presence of their chuck taps in the stroke system.

Tapping machine with its high precision and accurate tapping is very useful in different engineering fields to make different small products that can be used to build a great product.

9.What are general safety rules for using electric tapping machine?

Some safety rules are important to keep in mind when you are interacting to work with the electric tapping machine because your product will remain safe and secure along with the labor which is working with the machine.

- It is noticed by different doctors that most of the eye infection is happened to those person who works with different electric machine which reflects light like tapping machine does during holes threading.

- Please make sure to wear the glasses when working with the machine because these safety glasses will work as a shield to protect inner retina of your eyes.

- Always fix the product with the clump or any fixing component to stop the product from moving around.

- Never hold any metal material in your hand it may cause some damage on your hand or arm because the threading speed of the tapping machine is very insane.

- Stay away from the moving arm of the machine to provide wide angle to your working equipment.

These are some key rules that you must know to ensure the safety of yourself and your product as well.

10.What are the different work modes of the electric tapping machine?

There are three modes on which a tapping machine works.

Intermittent Tapping Mode

For this tapping mode a cantilever is used at the oscillation point which can tap up to the amplitude of 100nm. The oscillation provides a blind depth to the cantilever to accurately tap with the surface of the material which is similar to the blinding end of the product.

A probe is used to tap in the threaded hole which provides an accurate width and rotational speed to the drill for the tapping purpose.

Dynamic Tapping Mode

In this mode the cantilever and the probe does not make any contact which is why it is called dynamic or contactless tapping. Because the vibration of the probe and cantilever does not make any impact it is only because the product sample and the tapping tip of the drill are rarely contact with each other to make the tapping possible.

Contact Tapping Mode

In contact mode the cantilever works as a sensor to measure the depth of the tapping hole by going deep into it and then contact with the layer for making the tapping process accurate and precise.

The measurement of force that needs to be applied on the metal surface is calculated easily and then the tap head moves into the hole for making a thread hole useable for tapping purpose.

11.What is the speed of the normal electric tapping machine?

Electric Tapping Machine without base

Basically, the speed of the electric tapping machine depends on the automation level of the machine because an automatic machine during the tapping process will behave differently as compared to manual tapping machine.

Some semi-automatic tapping machines hold 200 RPM speed with the regulation of time period.

Speed of a normal electric tapping machine lies between 180 to 200 rpm because every machine does not poses the same power rate.

The installation of servo motor inside a machine is also very vital to define the speed of the machine.

Every machine works different so you can not say that every machine has the same speed ability because it is not possible when you compare number of factors that defines the speed.

12.How much power electric tapping machine required to perform its functions best?

The requirement of a power to work with the tapping process depends on the type of servo motor which is installed in the machine.

A high quality servo motor will require up to 440V of electric power to work with the tapping process because it is easy for the machine to utilize this energy and then precisely deliver it to different parts of the machine.

Most of the motors will cost you in terms of power consumption because they have a large size motors inside them that requires some extra energy to work on.

We will provide you servo motor which will enhance the productivity speed and it will take minimum amount of electric power to work with different kinds of materials for tapping purpose.