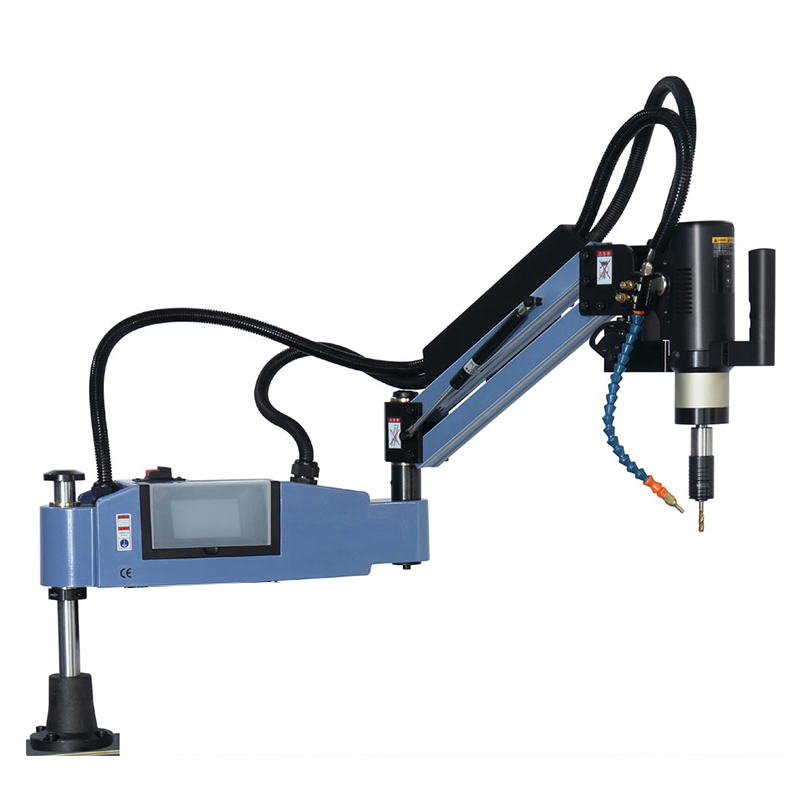

ELECTRI TAPPING MACHINE FEATURES:

| FA1910 | FA1912 | FA1916 | FA1920 | FA1916L | |

| Tapping capacity | M3-M10 | M3-M12 | M3-M16 | M3-M20 | M3-M16 |

| Voltage: 220/50hz | |||||

| Motor Power | 600W | 600W | 600W | 600W | 600W |

| Spindle speed | 1200rpm | 660rpm | 375rpm | 240rpm | 375rpm |

| Working Radius in Horizontal | 1045mm | 1513mm With extension arm |

|||

| Working Range in Vertical | 570mm | 729mm | |||

| Spindle taper | B16 | ||||

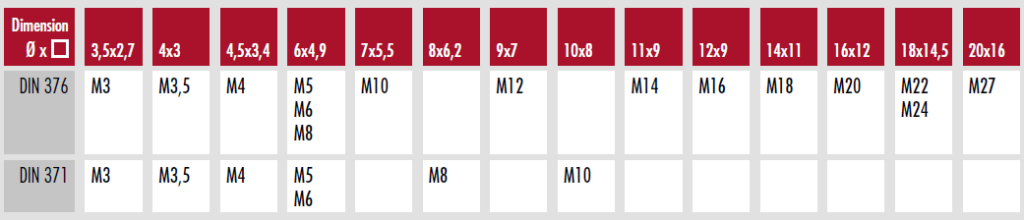

| Quick change chuck size | 19mm | ||||

| Tap collet | M3-M10 | M3-M12 | M3-M16 | M3-M20 | M3-M16 |

| Torque Max | 18N.M | 33N.M | 58N.M | 90N.M | 58N.M |

| N.W | 34kg | 34kg | 34kg | 34kg | 34kg |

| Overall Size | 700*600*220mm | 61*41*124 | |||

• With lower consumption compared with tradional pneumatic tapping machine.

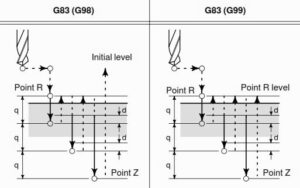

•Taps both blind and through holes with automatic depth control,tapping counter,torque value control, speed control easily via servo motor system.

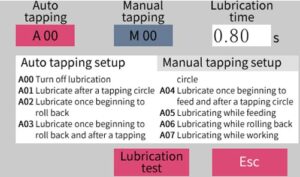

• Both manual or automatic tapping model available.

• Peak tapping model for harden materials tapping. (for holes that clog with swarf , harden materials)

• The arm equipped with bearings at all swivel points, provides weightless operation through the use of damper and permits the operator to bring the tap to the hole with ease.

• Highly flexible Faster tapping cycles.

METRIC, BSP, BSW, UNC, UNF, NPT IN DIN OR ISO standard chuck collet available

DIGITAL TOUCH SCREEN CONTROL Program in English, Spanish, Portuguese, Italian, Russian available.

• Servo motor with Torque protection and Ratchet Tap holder to avoid tap broken. And the torque can be manual adjusted if required

• Faster tap positioning with difficult locations –easier to reach holes

• Increases productivity – lowers tapping cost per part

• Touch screen easy set parameters, RPM and thread pitch to program auto reverse.

• With Optional Automatic MQL Minimum Quantity Lubrication System ,only a few milliliters of lubricants are spent per hour, ecological and economical solution compared with conventional cooling processes. and compressed air flow can be adjusted to blow away the iron filings easily.

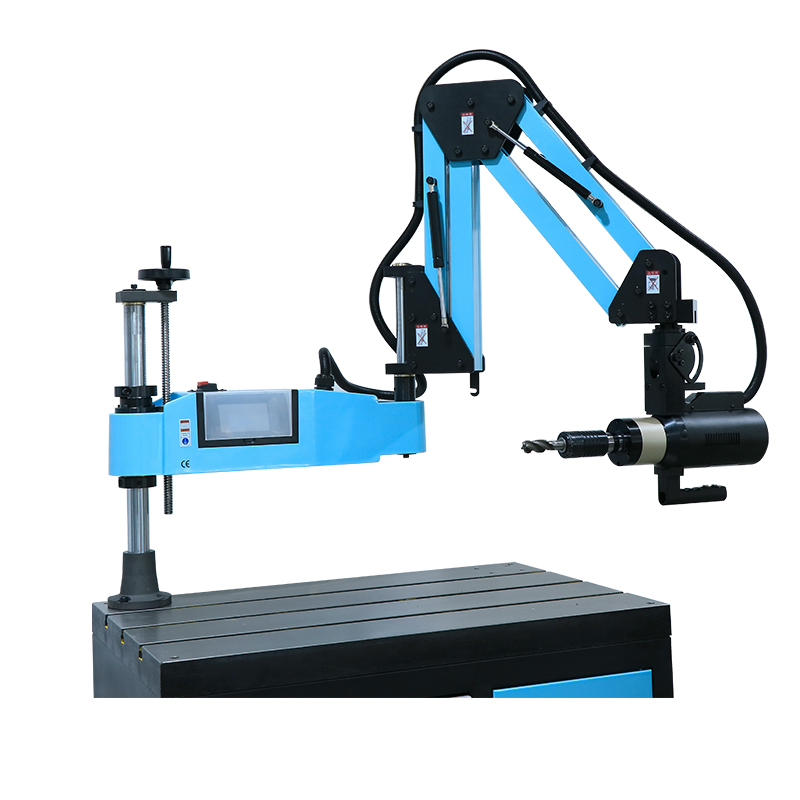

IRON STEEL WORKING TABLE TECHNICAL PARAMETERS

working table surface size: 900*600mm

Table surface with precision grinding treatment and M14 T-slot.

With Five sliding drawers and cabinets

Packing details:

Packed in export standard plywooden case with steel handle for convenient transport.

Tapping machine size 69*65*21cm 32kg Working table size 95*65*82cm 128kg

If our electric tapping machine can do Other operations:

- Countersink hole, tightening, Screwing, riveting, Helicoils inserts.etc.

Optional working table with oil recycling

And we made high quality Precision working table suface with Milling water sink and T-slot for our Spanish client.

Reviews

There are no reviews yet.