ST1600R Sheet Metal Deburring Machine

Technical Advantages

In the world of industrial sheet metal processing, it is common practice to round all sheet edges after cutting. By rounding edges, also known as edge breaking, you can achieve the desired radius on your sheet metal edge. This removes the sharpness from the sheet metal and prepares it specifically for further processing, for example for painting and coating

In general, During deburring, sharp edges are removed and the sheet metal edges are rounded. Depending on the application, it can be important to remove the sharpness of the edge. Larger radii in the range of 0.5 mm are necessary to prepare the sheet metal for reliable coating (painting, galvanizing). Occasionally, radii of up to 2.0 mm are required which can be achieved with Armpre machines as well

Vacuum table for processing small products (50 x 50 x 1 mm)

User comfort and ease of use has been a priority in the design of this deburring machine.

The HMI touchscreen is clear and simple to understand

low consumable usage, the energy efficiency and the optimal price-quality ratio. That makes it a perfect, versatile solution for processing different sheet metal parts.

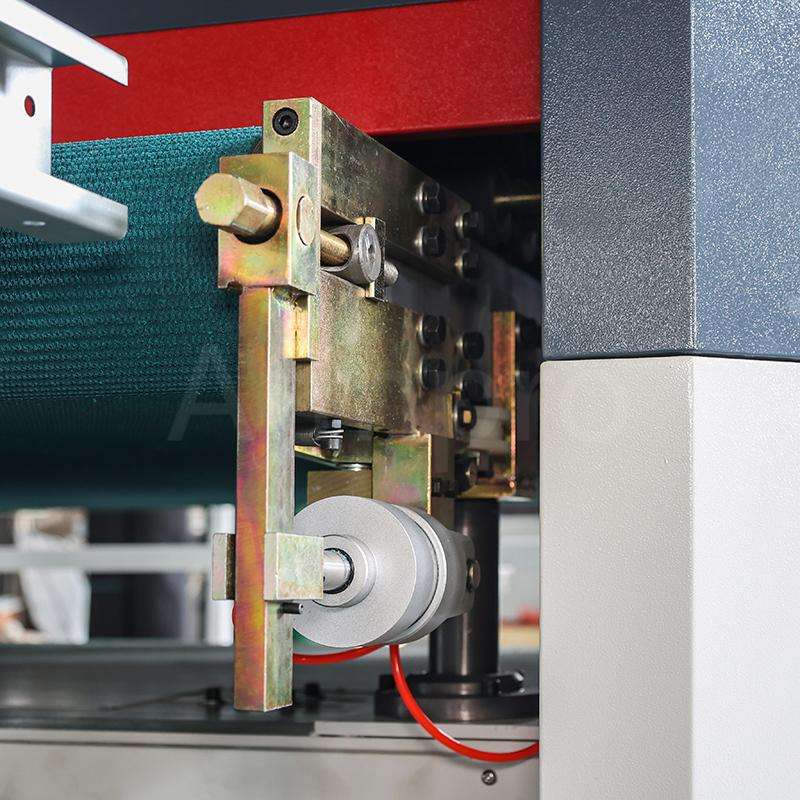

Equipped with a quick-change system for the tools (abrasives) to minimize set up time.You can simply remove the brushes and click them back in, without any tools needed!

The primary burr, which remains on flat and round parts after the previous work step, is removed with our modular machine attachments. Depending on the nature of the workpiece, this is done with Two grinding belt which abrasively removes the burr.

Our Armpre Shhet Metal Deburring Machine Supporting laser cutting machine, CNC stamping, various CNC processing or other machining deburring batch production line.

Equipment through straight line processing, sanding belt and multiple groups of sanding line wheel rotation, revolution, alternate, can be a real uniform removal of solid slag or parts surface, contour edge and hole edge burr, and uniform chamfering.

it can also be used for rust removal and oxidation layer on the surface of sheet metal according to the situation;Stainless steel surface simple wire drawing; Aluminum plate, copper plate surface treatment

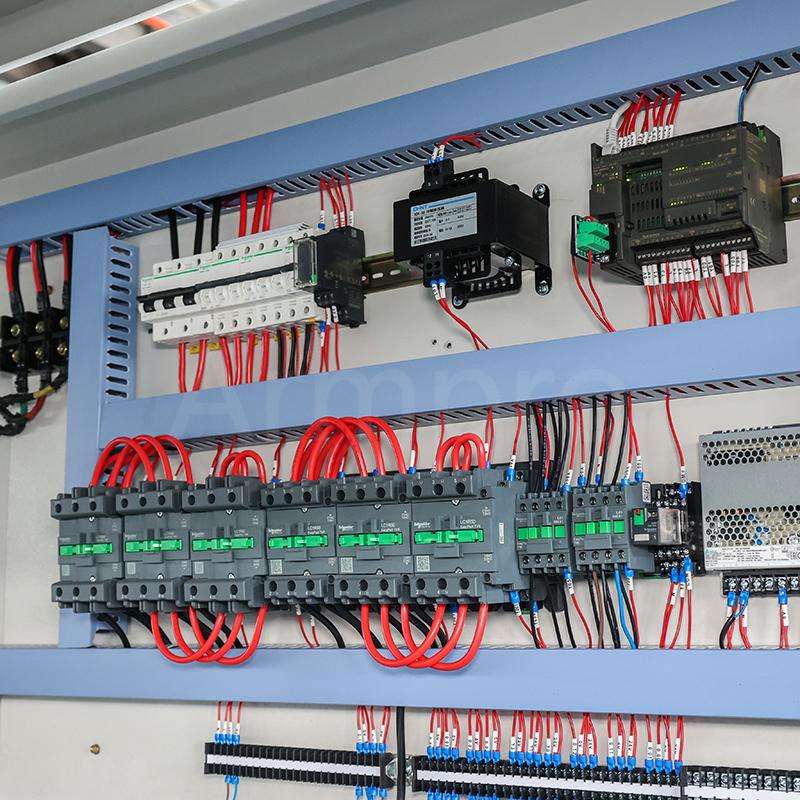

We have established strong relationships with world-renowned suppliers such as SIEMENSE

Mitsubishi Electric Autonics Schneider, and NSK to ensure the excellent performance of our machines.

| Item | Content | Specifications |

| Range of processing | Max working width | ≤ 1600 mm |

| Single-sided, dry | ||

| Mateiral thickness | 0.5 Up to 110 mm | |

| Power supply part | Input power source | 480 V / 3 phases / 60 Hz |

| Sanding belt drive motor *1set | 30 kw | |

| Sanding belt drive motor *1set | 22 kw | |

| Power of dust removal fan *1set | 5.5 kw | |

| Platform lifting motor *1 | 0.55kw | |

| Feed conveying motor *1 | 4 kw | |

| Eccentric rubber roller | Effective 1600mm* diameter 240mm* adhesive layer 20mm |

|

|

Parameter of operation |

Speed of sanding belt | 0 – 1700 rpm |

| Speed of conveyor | 2 – 25m/min | |

| The attachment | Sand belt size*1 set | 2000 mm*1620 mm |

| Conveyor belt dimensions | 6870 mm*1620 mm | |

| Thickness adjustment mode | automatic | |

| Control system | Panel control | HMI Touch Screen |

| Control | SIEMENSE PLC | |

| Thickness adjustment precision |

<0.05mm | |

| Working air pressure | 0.4-0.6Mpa |

Equipment features and advantages

Versatile Processing: Capable of handling various sheet metal sizes and thicknesses to accommodate diverse applications.

Adjustable Speed Settings: Features variable speed controls for both grinding belts and conveyor systems, allowing customization based on material and deburring needs.

User-Friendly Interface: Designed with an intuitive HMI control screen that simplifies operation and monitoring.

Robust Construction: Built with durable materials to withstand heavy use, ensuring long-term reliability and performance.

Efficient Dust Collection: Integrated dust collection systems to minimize airborne particles and maintain a clean working environment.

Offers adjustable worktable height to accommodate various operator preferences and improve ergonomics.

Safety Features: Includes emergency stop buttons and safety guards to protect operators during operation.

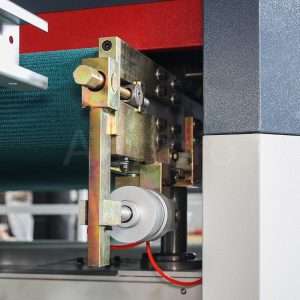

Low Maintenance Requirements: Designed for easy access to components, reducing downtime and simplifying maintenance tasks. Automatic deviation correction

Reviews

There are no reviews yet.