Why Armpre Machinery is Trusted

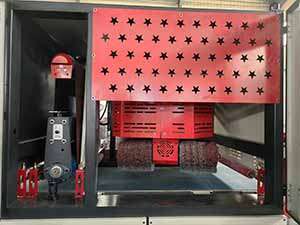

Welcome to Visist Our Sheet Metal Deburring Machine Factory

Welcome customers from any country come to visit us, we can show you the Sheet Metal Deburring Machine workshop, and show the Sheet Metal Deburring Machine production site.

The Buyer's Guide

Your Complete Buying Guide for Sheet Metal Deburring Machine Buying Guide Machine in 2024

1. What is a Sheet Metal Deburring Machine?

Introduction:

The sheet steel burring equipment is a typical customized tool in the metalworking market. To ensure premium and also exact components for a selection of usages its primary responsibility is to ravel sheet steel elements by eliminating burrs sharp sides and also problems.

Working Principle:

Mechanized therapies automate the removal of burrs from sheet steel making burring tools dependable and also constant. They squash steel parts making use of thermal power rolling systems, rough belts, or turning brushes.

Importance and Applications:

You'll find the automotive, aerospace, medical equipment, and general fabrication industries among the many fields that rely on these machines. As a result of their meticulous work, precision engineering, and adherence to industry standards everyone benefits from metal components that are free of burrs.

Benefits:

- Makes steel components look much better, function much better, plus be more secure.

- Makes producing simpler and also makes use of much less physical labor.

- Assists in fulfilling top-quality criteria together with lawful requirements.

- Reduce the variety of burrs and also mistakes that wind up in scrap, remodel, and also service warranty cases.

2. Why is important to remove the burrs via a sheet metal deburring machine?

For several factors, it is vital to make use of a sheet steel burring maker to get rid of burrs:

- Enhanced Safety:

Sharp burrs on steel elements posture a carcinogen. Employees managing the parts are shielded from cuts along with abrasions by eliminating them.

- Improved Functionality:

When collaborating with steel components burrs can hinder setting up and even damage makers. Components that have been burr are most likely to mesh quickly along with execute as anticipated lowering the probability of functional troubles as well as failings.

- Quality Assurance:

Metal elements look plus carry out much better with smooth, burr-free surface areas. Getting rid of burrs ensures that end products satisfy both the visual needs as well as the assumptions of the customer.

- Compliance with Standards:

The lack of burrs as well as sharp sides is a demand of numerous markets' high quality together with safety and security criteria for steel elements. Using a sheet steel burring device helps manufacturers follow these spec-plus guidelines.

- Prevention of Contamination:

Gradually burrs can create deterioration or contamination of the item by capturing particles or contaminations. The steel components are assured to last a long period as well as be dependable after deburring to get rid of these feasible impurities.

- Cost Reduction:

Minimized manufacturing prices as well as boosted total performance are 2 advantages of deburring which aid in saving remodel scrap and also guarantee cases triggered by burrs.

The removal of burrs utilizing a sheet steel burring maker is important for the safety and security, performance, performance, uniformity plus the economic situation of steel construction treatments.

3. How Do Deburring Processes Work?

The function of deburring is to enhance the top-quality effectiveness as well as safety and security of steel parts by getting rid of burrs, sharp sides as well as various other flaws. Deburring is achieved in a range of means each having its certain auto mechanics as well as usages:

- Manual Deburring:

Process:

Refine steel work surfaces by hand utilizing devices like brushes, data, or scrapes to get rid of burrs.

Application:

Perfect for one-off items or complicated settings up when precision is of vital value.

Advantages:

Enables the deburring of complex forms and also supplies control as well as versatility.

Disadvantages:

Slow, needs a great deal of human initiative plus isn't perfect for automation.

- Mechanical Deburring:

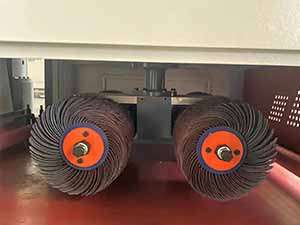

Process:

Automates the deburring procedure utilizing equipment that is fitted with turning brushes, unpleasant belts, or grinding wheels.

Application:

Perfect for elements with easy geometry or for automation.

Advantages:

Efficient at refining big amounts of components effortlessly as well as uniformity.

Disadvantages:

Maker configuration as well as upkeep might be essential originally.

- Thermal Deburring:

Process:

The treatment involves home heating the steel component to a factor where the burrs are thawed or charred off.

Application:

Helpful for smoothing off harsh places in detailed geometries or inside slim openings.

Advantages:

Promptly as well as properly gets rid of burrs without damaging the workpiece.

Disadvantages:

Heating can happen otherwise effectively managed with specialized tools.

· Electrochemical Deburring:

Process:

Gets rid of burrs from steel utilizing an electrolyte option and also an electrical present.

Application:

Designed for precise deburring of complicated geometries and intricate components.

Advantages:

Offers controlled deburring that is both precise and safe for the work piece’s surrounding areas.

Disadvantages:

The concentration of electrolyte and current density must be carefully controlled.

· Tumbling:

Process:

Using abrasive media with a tumbling barrel or chamber to remove burrs from metal workpieces. The barrel is then rotated.

Application:

It works well for deburring large quantities of small to medium-sized components.

Advantages:

Provides an efficient and economical way to deburr a large number of parts.

Disadvantages:

Surface finishing may necessitate extra procedures and yield variable results.

There are several considerations, including metal type, part geometry, production volume, and desired finish, that go into selecting the most appropriate deburring technique.

4. What size of parts can be deburred?

From tiny precision components to massive structural elements, sheet metal deburring equipment can handle it all. To give you an idea of what kinds of parts are usually durable, consider the following:

- Small Parts:

- These comprise complex and fragile parts utilized in precision engineering, such as electrical connectors, tiny brackets, or minuscule metal bits.

- To get rid of burrs from tiny components, use sheet metal deburring equipment that has abrasive belts or brushes for delicate deburring.

· Medium Parts:

- Automotive, aerospace, and manufacturing are just a few of the many industries that frequently use medium-sized parts.

- Metal housings, medium-sized brackets, engine parts, and gearbox parts are only a few examples.

- For the effective processing of medium-sized parts in bulk, deburring machines with customizable settings and conveyor systems are commonly utilized.

· Large Parts:

- Typical heavy industries that need large parts include construction, aerospace, and shipbuilding.

- These can be big metal enclosures, structural parts, or even sheet metal panels.

- huge items can be efficiently deburred using tumbling machines that have huge chambers and strong abrasive media.

· Versatile Capacity:

- A large variety of part sizes can be accommodated by the changeable settings and customizable solutions offered by several current sheet metal deburring machines.

- Machines can have their designs or capabilities adjusted to accommodate different part sizes, which is one example of a custom solution offered by manufacturers.

Ultimately, in the year 2024, sheet metal deburring machines provide the adaptability to work with components ranging in size from tiny precision bits to massive structural components. Before making a purchase, it is essential to assess your production requirements and take the deburring machine's capabilities into account.

5. Manual Deburring VS mechanical Deburring

To eliminate burrs from metal parts, two separate processes exist mechanical deburring and manual deburring. The two are compared here:

· Manual Deburring:

- Work that is done by hand.

- Achieving control and precision is within reach.

- Very time-consuming.

- Perfect for complicated or small-scale projects.

- Operates best with trained hands.

- Equipment investment is minimal at the outset.

- Mechanical Deburring:

- Streamlined procedure.

- It provides reliability and effectiveness.

- Perfect for mass manufacturing.

- Needs to be capitalized with machines initially.

- Easier to handle.

- Could use some upkeep every so often.

6. What is the difference between a WET deburring machine VS DRY deburring machine?

Method of deburring and use of coolant or lubricant are the main differentiating factors between wet and dry deburring machines:

· Wet Deburring Machine:

Process:

While deburring, use a liquid lubricant or coolant.

Coolant/Lubricant:

The tool and workpiece are cooled by the liquid, which reduces friction and heat buildup.

Benefits:

- Useful for removing debris and avoiding heat buildup, which can prolong the life of tools.

- Makes the surface of the workpiece appear smoother.

- Lowers the possibility of the component suffering heat damage.

Applications: - Fits materials like titanium and stainless steel that produce a great deal of heat when machined.

- Frequently employed in the production of aerospace, automobile, and medical device components.

· Dry Deburring Machine:

Process:

Removes burs without using lubrication or liquid coolant.

Operation:

Depends entirely on mechanical abrasion for burr removal.

Benefits:

- Because neither coolant nor lubricant is liquid, cleanup is a breeze.

- Because it does away with the need to dispose of coolant, it can be better for the environment.

- Since coolant systems are not necessary, this option may be more economical in the long run.

Applications:

- Work well with plastics and aluminum, which do not require coolant to deburr.

- Used frequently in the woodworking, electronics, and precision engineering industries.

To summarize, dry deburring machines depend only on mechanical abrasion, but wet deburring machines use liquid coolant or lubricant to decrease heat and friction. Materials compatibility, desired finish, and operating preferences are some of the elements that determine whether wet or dry deburring is better.

7. What are the different applications of a Sheet Metal Deburring Machine?

Certainly! The capacity of sheet metal deburring machines to eliminate burrs, sharp edges, and other flaws from metal workpieces makes them useful in a wide range of industries. A comprehensive rundown of the various uses is provided here:

- Automotive Industry:

- Disinfecting engine parts, including crankshafts, cylinder heads, and gearbox components.

- Working to improve stamped sheet metal components utilized in vehicle bodywork, chassis, and interior parts.

- Aerospace Industry:

- Cleaning up the engine, landing gear, and airframe components that have been precisely machined.

- Taking intricate aircraft parts, such as fuselage panels and turbine blades, and smoothing them out.

· Medical Device Manufacturing:

- Make sure that implanted medical equipment and surgical instruments are smooth and free of burrs to avoid irritating tissues.

- Perfecting X-ray and magnetic resonance imaging (MRI) systems and other precision machined components utilized in medical equipment.

· Electronics Industry:

- Metal components of electrical and communication devices, including housings, chassis, and heat sinks, are deburred.

- Taking stamped metal components utilized in electronics and computer gear and smoothing them down.

· Precision Engineering:

- Deburring machined components used in manufacturing machinery, tooling, and industrial equipment.

- Refining precision shafts, bearings, and gears for long-term use and trouble-free operation.

· Metal Fabrication:

- Sheet metal components, signs, and furniture that have been plasma or laser cut can have their edges smoothed down.

- For the sake of both appearance and safety, burrs are being removed from welded assemblies and manufactured structures.

· Plumbing and HVAC Industry:

- Mechanical air conditioning (HVAC) ducting, pipes, and fittings deburring.

- Fixing and improving the fit and functionality of plumbing fittings, valves, and connectors.

Sheet metal deburring machines are useful in many different fields, and they help make metal parts more reliable and secure.

8. What are the advantages and disadvantages of sheet metal deburring machines?

Certainly! Here's a summary of the advantages and disadvantages of sheet metal deburring machines in points:

- Advantages:

- Improves the quality of the part by smoothing off rough spots and sharp edges.

- Reduces production time and increases throughput by automating the deburring process.

- Boosts production efficiency by cutting down on labor expenses and rework.

- Adaptable to a wide range of materials, part shapes, and sizes, allowing for more customizability in production.

- Reduces the likelihood of worker injury and equipment damage by getting rid of sharp edges.

- Disadvantages:

- Can be quite expensive initially, particularly for automated or high-quality systems.

- To maintain the devices performing well and expand their life regular upkeep is required.

- To correctly run coupled with keeping the gadgets, drivers could call for specialized training.

- It might be essential to make use of specialized treatments or devices to get rid of particular products effectively.

- Might not be the most effective option for each burring task, specifically when taking care of components with difficult or ornate geometries.

While there are lots of advantages to making use of sheet steel deburring equipment in production such as greater item top quality, even more effectiveness, and also reduced prices there are likewise some vital factors to consider to bear in mind such as the first financial investment, upkeep requires, as well as product restrictions.

9. How to Choose the Right Abrasives for Your Metal?

The steel kind, surface needed plus application details are all essential factors to consider when picking the suitable abrasives for steel. To assist you pick intelligently we have consisted of adhering to the directions:

- Identify the Metal Type:

- Metals differ in solidity plus surface area coating.

- You might be collaborating with steel, lightweight aluminum, stainless steel, or copper.

· Determine the Application:

- Choose abrasives for deburring, grinding, brightening, or surface area prep work.

- Varying applications require differing grit dimensions, product, along with aggression.

· Assess Surface Finish Requirements:

- Choose a harsh, matte, satin, or mirror-like surface.

- Finer abrasives with greater grit dimensions offer smoother coatings than coarser ones.

· Choose the Abrasive Material:

- Common alternatives consist of lightweight aluminum oxide, silicon carbide, ceramic alumina plus zirconia alumina.

- Aluminum oxide is inexpensive and flexible for metal grinding and polishing.

- Silicon carbide's sharp cutting and high-temperature resistance make it perfect for hard metals and non-ferrous materials.

- Ceramic and zirconia alumina abrasives are for heavy-duty metal grinding because they cut aggressively and last long.

· Consider Environmental Factors:

- Choose waterproof or dust-resistant abrasives for damp or dusty situations.

- Environmental restrictions may necessitate specific abrasives or dust extraction devices.

· Evaluate Grinding Pressure and Speed:

- Durable, heat-resistant abrasives may be needed for higher grinding pressure and speed.

- Under aggressive conditions, use high-speed grinding and heavy stock removal abrasives.

· Test and Experiment:

- Try several abrasives and grit sizes to find the best fit for your metal and application.

- Testing should consider material removal rate, surface polish, and abrasive life.

These methods will help you choose the proper abrasives for metalworking by evaluating metal type, application, surface finish requirements, abrasive substance, environmental conditions, and testing. Performance, quality, and metal processing will be optimized.

10. What key factors should we consider when purchasing a Sheet Metal Deburring Machine?

To make sure you have the correct equipment for your needs, there are a few important things to think about when buying a sheet metal deburring machine. Presented here are the most important considerations:

· Deburring Method:

You need to figure out if mechanical, vibratory, brush, or thermal deburring is the right procedure for your application.

· Type of Material:

Before purchasing a deburring machine, it is important to research which materials it is compatible with. Some examples of such materials are steel, aluminum, and stainless steel.

· Part Size and Geometry:

Make sure the machine can handle the pieces you'll be deburring by taking their size, shape, and complexity into consideration.

· Production Volume:

To choose a machine that can efficiently satisfy your throughput goals, you must first determine your production volume requirements.

Automation Level:

Depending on your production needs and budget, choose the level of automation you desire, from manually operated machines to semi-automatic or fully automatic systems.

· Future Expansion:

Think about the machine's scalability and whether it can handle your production needs now and in the future.

When purchasing a sheet metal deburring machine, it's important to keep these things in mind so you can get the equipment that works for you, boosts productivity, and produces high-quality results.