Why Armpre Machinery is Trusted

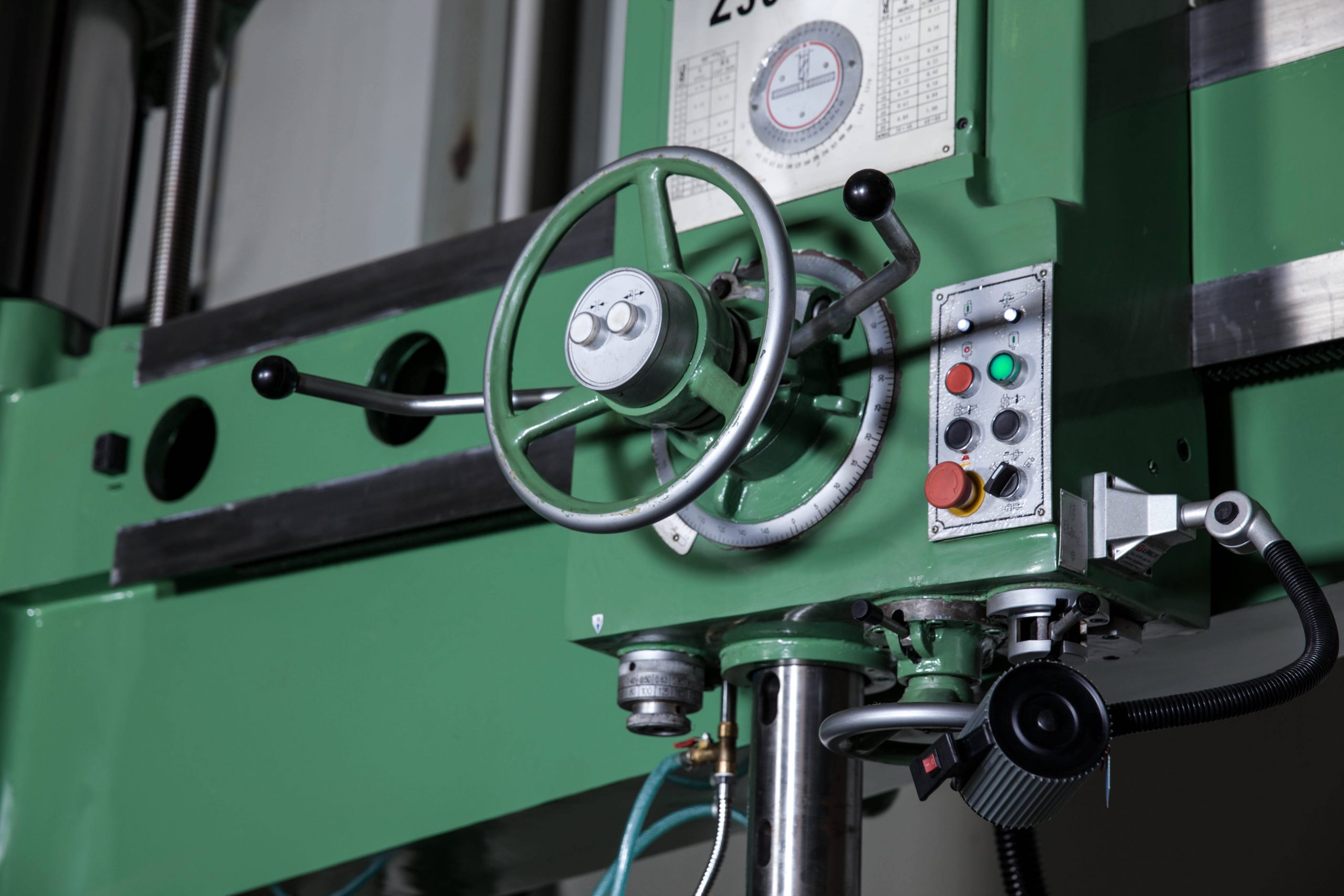

Welcome to Visist Our Radial Drilling Machine Factory

Welcome customers from any country come to visit us, we can show you the Radial Drilling Machine workshop, and show the Radial Drilling Machine production site.

The Buyer's Guide

Radial Drilling Machine:The Complete Buying Guide In 2024

The radial drilling machine is an indispensable tool for precise and adaptable hole drilling in machining. You must understand the complexities of radial drilling machines to make educated decisions, regardless of whether you are an experienced expert or a beginner enthusiast. From their basic features to maintenance tips in 2024, this buying guide for radial drilling machines tries to clarify their mystery.

1. What are different Drilling Machines?

There is a wide variety of drilling machines available, each specialized to a particular task.

Here are some common types:

- Portable Drilling Machine:

For simpler drilling jobs, try using a portable electric drill, sometimes called a hand drill or just a drill. Because of its adaptability, it is ubiquitous in homes and garages.

- Pillar Drill Machine:

A pedestal-type drill, often called a bench drill, is attached to a stand or a bench. It's more stable and precise than portable drills, making it ideal for larger drilling jobs.

- Radial Drilling Machine:

Drilling huge workpieces is no problem for this equipment because of its mobile radial arm. Its primary function in industrial contexts is to facilitate heavy-duty drilling operations.

- Upright Drilling Machine:

An upright drilling machine is quite similar to a pillar drill; however, it differs primarily in that it includes a moveable table, giving the operator greater freedom of movement when setting the workpiece.

- Gang Drilling Machine:

It can drill numerous holes in a workpiece at once because of its multiple drill heads that are positioned on a single base. This works well for mass manufacturing.

- Sensitive Drilling Machine:

It's an easy-to-carry, compact drilling equipment perfect for pinpoint work. It is frequently utilized in tool rooms and when crafting instruments.

- Automatic Drilling Machine:

It is not necessary to manually operate these machines for drilling tasks because they are fully automated. They have widespread application in fields that value efficiency and precision.

- CNC Drilling Machine:

The drilling machines known as computer numerical control (CNC) are controlled by a computer, which enables them to perform drilling tasks that are both precise and sophisticated. They are made use of frequently in a selection of sectors, consisting of the aerospace as well as vehicle manufacturing industries.

- Deep Hole Drilling Machine:

To pierce deep openings with a high level of precision, these devices have been specially constructed. Mold-making oil & & gas as well as aerospace are simply a few of the sectors that use them.

Every sort of exploration equipment has advantages of its own and is picked according to the specific requirements of the work at hand.

2. What is meant by Radial Drilling Machine?

One identifying function of radial exploration equipment is their movable radial arms which can be placed in numerous methods around a main upright column. To exactly position the exploration head over the work surface the radial arm can generally be changed both flat as well as up and down.

An essential component of any radial drilling machine is:

- Radial Arm:

The radial arm is swivel-able and also prolongs flat from the upright column. This arm sustains the exploration head and also allows you to readjust its setting about the column to fit work surfaces of differing dimensions.

- Worktable:

Worktables are basic devices on numerous radial exploration equipment either developed right into the maker or attached to the column. The work surface can be sustained throughout exploration by this flexible worktable, which can be used to high and also angle.

- Vertical Column:

The exploration head, as well as the radial arm, are sustained by the upright column. It is likewise where the securing, as well as upright activity systems, are situated.

- Drill Head:

At the actual end of the radial arm is the exploration head which is accountable for holding the exploration device. It can customize the exploration deepness by relocating up and down.

- Power Feed:

The exploration head can be instantly relocated up and down throughout exploration procedures on several radial exploration devices many thanks to power feed devices. Particularly for drilling jobs that require repetition, this feature greatly improves efficiency and precision.

When working with big and heavy workpieces, radial drilling machines are a frequent tool for the job. Their adaptability to a variety of drilling tasks, including drilling several holes at different depths, slanted holes, and precisely positioning the drill head over the workpiece, is due in large part to the radial arm's versatility. When accuracy and adaptability are paramount, they shine.

3. What are some common uses of a Radial Drilling Machine?

Drilling holes in big and heavy workpieces is a regular task for radial drilling machines, which are multipurpose tools used in many different sectors. Uses such as these are common:

- Metalworking:

Drilling, reaming, tapping, countersinking, and boring are common tasks performed on metal components by radial drilling machines in metalworking shops. Among the many materials they are capable of working with are cast iron, steel, and aluminum.

- Construction:

Radial drilling machines are commonly used in construction projects to bore holes in structural steel plates, columns, and beams. When constructing buildings, bridges, and other structures, they are important for boring the holes that link the steel parts.

- Manufacturing:

Radial drilling machines are vital in the creation of precise parts for industries including aerospace, automotive, and equipment. These machines are essential for drilling holes in different materials with exact dimensions and alignments.

- Shipbuilding:

To drill holes in various shipyard components, including hull plates, decks, bulkheads, and frames, radial drilling machines see extensive use. Ships and maritime vessels couldn't be assembled or built without them.

- Repair and Maintenance:

In the realm of repair and maintenance, radial drilling machines are essential instruments. They drill holes for fasteners, repairs, or alterations, and are thus useful for fixing machinery, equipment, and structures.

- Woodworking:

Radial drilling machines are most commonly used in metallurgy, although they can be modified to do woodworking as well. On occasion, you might see them employed in woodworking shops to drill holes in wooden parts in a consistent and precise manner.

- Tool and Die Making:

When it comes to the production of dies, molds, and many other tooling components, radial drilling machines are frequently utilized in the tool and die manufacturing industries. The drilling of holes that are necessary for mounting components and the creation of complicated geometries is made easier by such devices.

- Mining and Construction Equipment:

Radical drilling machines are utilized in the mining and construction industries to drill holes in heavy machinery components, such as excavator booms, buckets, and frames. Additionally, these machines are utilized to drill holes for blasting reasons in mining operations.

Radial drilling machines are vital in many different industries and applications due to their adaptability, precision, and capacity to handle large and heavy workpieces.

4. What are mainly features of radial drilling machine?

Drilling openings in huge work pieces is a normal job for radial exploration equipment which discovers extensive applications in the building and construction as well as metalworking industries. Amongst its essential features are:

- Radial Arm:

It is feasible to relocate the radial arm of the equipment in straight instructions along the column of the maker while it is built. In addition, this radial arm can revolve around the column which allows exploration to be carried out at a selection of angles as well as settings.

- Adjustable Height:

To match a selection of work surface dimensions the radial arm is usually up and down flexible along the column.

- Versatility:

Several drilling procedures, consisting of exploration, reaming, touching plus countersinking, are within the abilities of these makers.

- Large Work Area:

Exploration of large as well as hefty work surfaces is not a problem for radial exploration makers due to their large work locations.

- Powerful Motor:

They have solid electric motors that offer the torque required to pierce with steel and also various other difficult products.

- Drill Head:

The drill little bit is held in position by the pierce head that lies at the end of the radial arm. To fulfill a range of exploration requirements the drill head can be altered for rate, feed price, as well as deepness.

- Precision and Accuracy:

Furnished with functions like deepness quits as well as electronic readouts, radial exploration devices are indicated to generate exploration outcomes that are specific as well as precise.

- Safety Features:

These days, radial drilling machines have safeguards like automatic shut-off systems, protective guards, and emergency stop buttons to make sure nobody is hurt.

Because of their adaptability, accuracy, and capacity to manage massive workpieces, radial drilling machines are fundamental equipment in the construction and manufacturing industries.

5. How much does Radial Drilling Machine cost?

Size, capacity, features, and brand all play a role in the wildly varying prices of radial drilling machines. In general, these are the prices:

- From $3,000 to $20,000 you may get a small to medium-sized radial drilling machine that is good for light to medium-duty drilling jobs.

- Costs can range from twenty thousand to one hundred thousand dollars, or even more, for larger, more feature-rich, industrial-grade radial drilling machines.

- It is possible to spend more than $100,000 on a radial drilling machine that is both specialized and custom-built for a particular job.

These are only ballpark figures; the real price could differ depending on things like the quality of the brand, the nation of production, and any extra features or accessories. For requirements-specific pricing, it's best to get in touch with suppliers or manufacturers directly.

6. How to use radial drilling machine safety?

Preventing injuries and mishaps while using a radial drilling machine is of the utmost importance. Please adhere to the following safety protocols:

- Read the Manual:

Make sure you read and understand the manufacturer-supplied manual for your machine. Important details on use, upkeep, and safety precautions are included in it.

- Wear Safety Gear:

Wearing safety goggles, gloves, and shoes with closed toes is essential for protecting yourself from flying objects, coolant splashes, and other potential dangers.

- Inspect the Machine:

Look for damage, loose parts, or anomalies on the radial drilling machine before you run it. Make sure that every guard is operational and in their designated positions.

- Secure Workpiece:

To keep the workpiece from shifting while drilling, secure it firmly to the vice or drilling table. Accidents and injuries might occur due to workpieces that are not secured.

- Adjust Speed and Feed:

Drilling materials have different recommended speeds and feed rates. For the best settings, check the machine handbook or refer to the machining instructions.

- Use Proper Tools:

Be sure to use the right size and kind of drill bit for the material you're drilling into. Poor hole quality or broken tools are consequences of using the incorrect tool.

- Start Slowly:

Start drilling at a slow pace and raise it as you go. The drill bit could bind or shatter if the motor is started suddenly or turned on at high speeds.

- Avoid Loose Clothing and Jewelry:

Stay put and don't wear anything that could get entangled in the machine's moving parts, such as loose clothing, jewelry, or long hair.

- Keep Hands Clear:

While the drill is in use, you should not put your fingers or hands near the bit or any other moving component. Instead of handling chips or trash with your hands, try using a brush or an air blaster.

- Turn Off Power When Not in Use:

While the machine is not in use, particularly when changing tools or doing maintenance, be sure to turn off the power.

- Stay Alert:

Keep your focus and ignore any interruptions as you operate the equipment. For safe operation, vigilance is paramount.

- Emergency Stop:

Make sure you know where to find the emergency stop button and how to press it in case of an unforeseen scenario or emergency.

Contribute to the prevention of accidents and the maintenance of a safe working environment by using the radial drilling machine by these safety standards.

7. What is mainly parts of radial drilling machine?

Most radial drilling machines have the following main parts:

- Base:

The machine as a whole is supported and stabilized by the base. Cast iron is substantial in weight, it dampens vibrations caused by drilling.

- Column:

The drilling head and radial arm are supported by the column, a vertical structure installed on the base. It makes the drilling operation more stable and firm.

- Radial Arm:

You can spin the radial arm around the column, which extends horizontally from it. Drilling workpieces of varying sizes is made possible by adjusting the distance of the drilling head from the column.

- Drilling Head:

The motor, spindle, and other parts required for drilling are housed in the drilling head. To change the depth of the hole, it can be moved vertically along the radial arm.

- Spindle:

Attached to the drill bit or cutting tool is the spindle, a shaft that rotates. It generates the required rotating motion for drilling and is powered by an engine.

- Motor:

Drilling machines rely on motors to power their spindles and other moving components.

- Table:

On certain radial drilling machines, you can find a worktable that is either attached to the column or fixed on the base. This table may be adjusted in height and angle to make drilling operations easier. The workpiece is put on top of it.

- Control Mechanism:

To change the radial drilling machine's head and spindle's position, speed, and feed rate, the operator can use electronic controls, levers, or handles.

These are the fundamental components of a radial drilling machine; however, the exact designs could differ from one maker and application to another.

8. When would you choose to use a radial drilling machine?

If you need to drill holes in big or heavy workpieces that aren't easy to carry to a stationary drill press, a radial drilling machine is a good choice. When working with massive metal components or constructions, like steel beams, plates, or castings, this tool comes in handy for drilling holes.

Some possible uses for a radial drilling machine are as follows:

- Large workpieces:

A radial drilling machine's mobility allows it to access previously inaccessible areas of large, heavy workpieces, making it an ideal tool for situations where a fixed drilling machine would be impractical.

- Heavy-duty drilling:

Because of its robust build and powerful motors, radial drilling machines can manage demanding drilling jobs. They find widespread application in the building, industrial, and metal fabrication sectors.

- Variable angle drilling:

These machines are great for jobs that call for drilling holes at a variety of angles or places thanks to their adjustable radial arm.

- Production drilling:

Radial drilling machines can be configured for repeating drilling operations, which improves productivity and consistency in production environments where precision drilling of large quantities of parts is required.

- Versatility:

Radial drilling machines are adaptable for a wide range of drilling tasks due to their ability to accommodate a variety of drill sizes and kinds.

When portability, power, and adaptability are paramount, a radial drilling machine is an indispensable instrument for jobs involving the drilling of holes in massive or heavy workpieces.

9. What is the main advantage of the radial drilling machine?

Certainly, here are the main advantages of a radial drilling machine summarized in points:

- Versatility:

You don't have to move the workpiece at all to use a radial drilling machine; it can drill holes at any angle and in any location.

- Adjustable Radial Arm:

The drill head may be easily adjusted on the radial arm to suit workpieces of varying sizes and shapes.

- Large Drilling Capacity:

Radial drilling machines can typically handle larger workpieces and drill holes of higher depths due to their larger drilling capabilities compared to other types of drilling machines.

- Ease of Use:

Anyone from novices to seasoned machinists may use these machines with ease because of how simple they are to operate.

- Efficiency:

The fast placing and angling capacities of radial exploration devices significantly improve exploration performance, reducing configuration time and optimizing performance.

- Cost-Effectiveness:

Radial exploration makers are a prominent selection in several workshops and also production centers because of their cost contrasted to various other specialized exploration tools.

- Suitability for Various Industries:

Their versatility coupled with the capability to collaborate with different products makes them important in several areas, including metallurgy, structure synthesis, and also upkeep.

As a result of these advantages, radial exploration makers are essential in lots of machining and also production procedures.

10. What are the disadvantages of radial drilling?

Certainly, here are some disadvantages of radial drilling:

- Limited Reach:

The exploration head of a radial exploration maker is completely placed, restricting the maker's reach. As a result of this, it might be tested to drill openings in huge or otherwise hard-to-reach workpieces.

- Lack of Precision:

For complex or advanced exploration work, radial exploration cannot be as exact as various other, even more contemporary exploration approaches. Precision in opening place plus dimension can be endangered as a result of this.

- Slower Speeds:

For top-notch production procedures specifically the slower running prices of radial exploration devices various other exploration techniques can influence efficiency.

- Setup Time:

It could take a great deal of time to establish a radial exploration maker for a details exploration task, especially if the exploration head requires to be changed many times to get it ideal.

- Limited Automation:

Unlike state-of-the-art COMPUTER NUMERICAL CONTROL (Computer Numerical Control) exploration systems, radial exploration equipment generally has restricted automation abilities demanding higher human communication. General effectiveness might endure as well as labor costs might climb because of this.

- Maintenance Requirements:

For radial exploration makers to operate at their finest and also prevent malfunctions, regular upkeep is important. Operating costs can be raised by doing jobs such as lubrication, placement assessments plus changing worn-out components.

- Safety Concerns:

As a result of the fast-revolving exploration little bit and also the opportunity of flying particles, utilizing radial exploration equipment can be harmful. One should have appropriate security methods plus training to reduce the influence of these risks.

- Limited Flexibility:

The key application of radial exploration devices is the exploration of openings in both levels coupled with bent surface areas. They could not depend on the job of milling or touching, which would seriously limit their effectiveness in the commercial setup.

When contrasted with modern, more sophisticated drilling technology, these drawbacks show how radial drilling machines fall short.

11. How many movements does a radial drilling machine have?

In most cases, a radial drilling machine will have three main movements:

- Radial Movement:

The radial head can be relocated flat along the arm that expands from the equipment's column many thanks to this motion. It allows for a range of possible drill positions relative to the column.

- Vertical Movement:

Along the maker's column, this activity enables the exploration head to fluctuate. It regulates how deep the hole can be dug.

- Swing Movement:

The full arm and drill head assembly can spin around the column thanks to this motion. It allows you to relocate the drill while it's on the work surface. Radial exploration devices are exceptionally functional as a result of these 3 activities. They can pierce openings at various angles as well as various placements on a workpiece.

12. What precautions should be taken when using a radial drilling machine?

In the lack of adequate safety and security actions running a radial exploration maker lugs the danger of injury. To maintain everybody, secure below are some actions to take:

- Read the Manual:

Understand the manual for the equipment. It provides you a review on exactly how to run it, just how to maintain your security, and also what to do when it malfunctions.

- Wear Appropriate Clothing:

Avoid any things that might come to be entangled in the maker's relocating components such as loosened garments or precious jewelry.

- Safety Gear:

Safety glasses, earplugs, and also handwear covers are all instances of PPE that need to be used at all times.

- Inspect the Machine:

Inspect the maker for imperfections, loosened parts, or damages before utilizing it. Make certain every safety and security information waits.

- Secure Workpiece:

You avoid any unanticipated movement or spinning of the workpiece while drilling, make sure you clamp or otherwise stabilize it securely.

- Adjust Speed and Feed Rate:

Drilling at the wrong speed or feed rate might cause the tool to overheat and break.

- Use Coolant:

To minimize heat generation and friction, use a suitable coolant or lubricant when drilling metals.

- Avoid Overloading:

Never put more strain on the machine than it can handle. The maximum drilling capacity can be found in the manual.

- Keep Hands Clear:

Avoid getting your hands on the drill bit chuck or any other moving elements of the machine.

- Stop in Emergency:

Find the emergency stop button and practice using it in case you need to.

- Training:

Before using the radial drilling equipment, make sure the operators have received adequate training.

- Maintain Good Visibility:

Get yourself positioned where you can see the controls and the drilling action.

- Switch Off Before Maintenance:

Never make any changes or repairs to a machine until you have turned it off and allowed it to stop completely.

- Avoid Reach-ins:

While the machine is running or spinning, you must never reach into it to touch the moving parts.

- Stay Alert:

Make sure you stay fully engaged and concentrated while you operate the equipment. Stay focused to prevent mishaps.

To use a radial drilling machine safely, it is important to follow certain measures.

13. What is difference between Radial Drilling machine and Pillar drilling machine?

While both radial and pillar drilling machines can bore holes in a variety of materials, these two tools serve rather different purposes.

- Structure and Design:

Pillar Drilling Machine:

The drill head and worktable are supported by a vertical column, which is also called a pillar, in this type of bench drilling machine. Attached to the worktable is the drill head, which swivels vertically along the pillar.

Radial Drilling Machine:

The arm can be rotated radially around the column, which is supported by a huge column. This arm holds the drill head, which might be changed up and down for exploration at different angles and also placements.

- Flexibility:

Pillar Drilling Machine:

Although they do not offer you much freedom to relocate the drill head, column exploration devices are terrific for making openings on small work surfaces.

Radial Drilling Machine:

Radial drilling machines supply even more flexibility in the drill area about the work surface given that the drill head can be relocated both flat as well as up and down. Due to this, you might utilize them to pierce openings at various angles as well as right into bigger work surfaces.

- Size and Capacity:

Pillar Drilling Machine:

In contrast to radial drilling machines, they are frequently a lot more portable and also tend to be smaller. They pertain to pierce procedures that are much less required as well as for work surfaces that are smaller sized.

Radial Drilling Machine:

Much more significant in dimension and also weight as a result of the existence of the radial arm as well as the ability to take care of even more significant work surfaces. Along with having the ability to approve bigger work surfaces, they can do function that calls for tougher exploration.

- Applications:

Pillar Drilling Machine:

To pierce exact openings in products such as timber, steel, as well as plastic, this device is often made use of in building workshops, garages as well as various other small-scale manufacturing centers.

Radial Drilling Machine:

When drilling jobs need versatility, accuracy, as well as the capacity to manage bigger work surfaces these devices are normally located in bigger production centers, hefty design industries as well as building websites.

Although both devices are made use of for exploration the choice of either a radial exploration maker or a column exploration equipment calls for factor to consider of several requirements consisting of the measurements of the workpiece, the level of adaptability that is essential as well as the degree of accuracy that is needed for the exploration procedure.

14. What are Radial Drilling Machine Maintenance Tips?

For the longest life, greatest reliability, and safe operation of a radial drilling machine, regular maintenance is necessary. Here are some radial drilling maintenance tips:

- Regular Inspection:

Inspect visually the machine regularly looking for damage wear and tear or anything out of the ordinary. Take special note of the drill chuck, belts, pulleys, gears, and bearings.

- Cleaning:

Clean dirt, dust, or coolant off the machine frequently. Use proper cleaning materials and equipment to remove accumulated grime carefully so as not to damage any fragile parts during this process.

- Coolant System Maintenance:

Make certain that you constantly have a well-working coolant system in your radial exploration equipment. You can stop overheating by cleansing or altering filters for coolants frequently while at the very same time checking coolant degrees to maintain effectiveness in reducing high.

- Lubrication:

Follow the manufacturer’s recommendations about lubrication schedules and lubricants used; these are aimed at reducing friction thereby extending the lifetime of moving components such as gears, slides, and bearings.

- Belt Tension:

Frequent checking and adjustment of belt tension should be done to maintain proper power transmission and avoid slipping. If the belts hang, they might trigger ineffectiveness plus damage the equipment.

- Electrical Components:

Examine if all electric components such as cables, ports, buttons, and so on, are functioning correctly. Additionally guarantee there are no frayed cable televisions, loosened links, or subjected cords.

Adhere to these upkeep ideas to maintain your radial exploration maker at its ideal; conserve downtime as well as optimize performance.

Conclusion:

To conclude the Ultimate Buying Guide for Radial Drilling Machine in 2024 maintains precision, power, coupled with adaptability. Enhancements in contemporary innovation concentrate on devices geared up with digital controls and also automated features combined with sturdy safety measures.

Consider variables such as pin price expedition capability combined with developing high quality to make certain suitable efficiency and also durability. Inevitably acquire a manufacturer that straightens with your specific demands as well as budget plan combined with lasting purposes for boosted efficiency coupled with performance in your procedures.