NPT vs NPTF: Understanding the Differences and Applications

Introduction

When it comes to threaded pipe systems, the type of thread must be selected correctly in order to achieve good compatibility, sealing, and general performance.

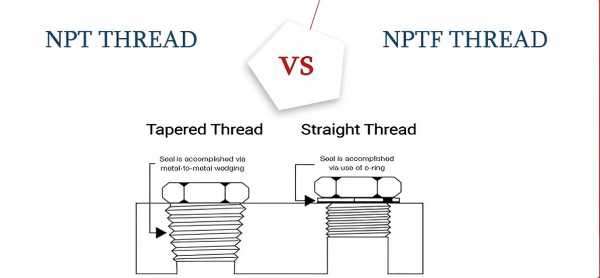

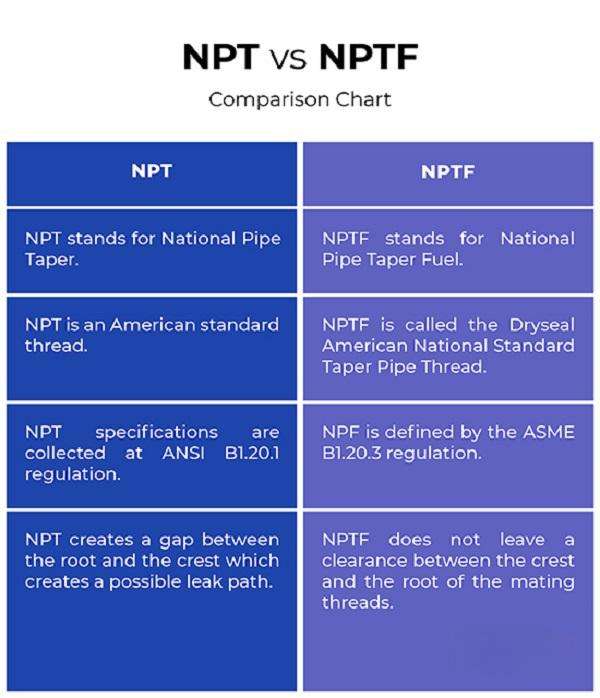

The types of threads most familiar with industrial and plumbing applications include NPT (National Pipe Taper) and NPTF (National Pipe Taper Fuel). Although they present the air of revolving and turntables and are meant for similar purposes, they are designed for different purposes.

This guide will explain NPT vs NPTF threads in detail, which kind is suitable for use, and how to establish that you are using the right thread.

1. What is NPT?

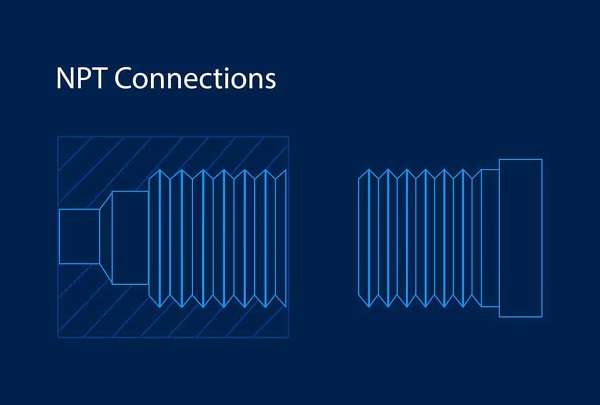

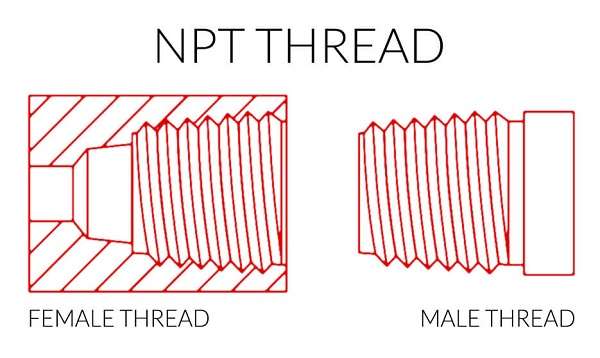

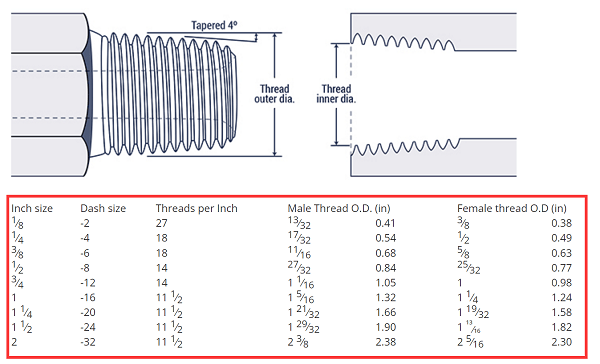

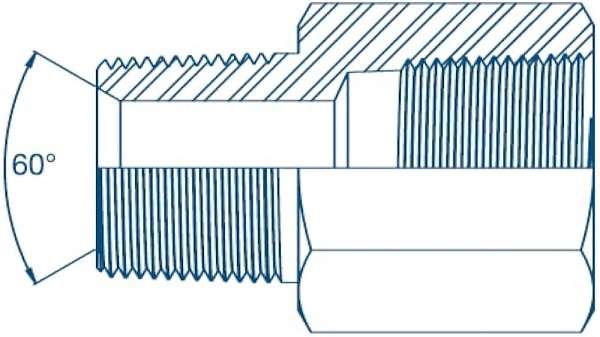

NPT, or National Pipe Taper, is a classification of tapered threads with references to pipes used to create leak-proof joints in piping systems. The threads on NPT fittings have a taper. That is to say, the diameter reduces progressively along the length of the thread.

As the round threads extend from a smaller to a larger diameter, interlocking is achieved when two NPT threads are screwed together and with an interference fit in connection with a sealing component such as thread tape or pipe dope for leak-tight sealing.

NPT threads are built in accordance with the standard of the American National Standards Institute B1.20.1, and are used in plumbing systems, gas, and hydraulic systems around North America.

The taper angle of 1.793 degrees provided also ensures that each thread is forced to bear against the other and gives a seal appropriate for pressure applications.

2. NPT Application

NPT threads are universal and are used in different sectors of the economy. Common applications include:

- Plumbing Systems: Nowem uses NPT threads in water, gas, and steam lines, and the type of thread ensures a safe seal against leakage.

- Hydraulic systems are employed to connect structural parts like valves and cylinders to the pumps in hydraulic circuits.

- Industrial Equipment: NPT threads are used on compressors, boilers, and other equipment that requires pressure-tight joints.

- Oil and Gas Industry: Today's pipelines and most of the fittings used in oil and natural gas transportation employ NPT threads due to their sealing characteristics.

- HVAC Systems: In heating, ventilation, and air conditioning systems, NPT threads are employed to join ducts and pipes.

Though NPT threads offer a sealing capability, other sealing components are necessary for leak-proof areas, particularly areas exposed to high pressure or high temperature.

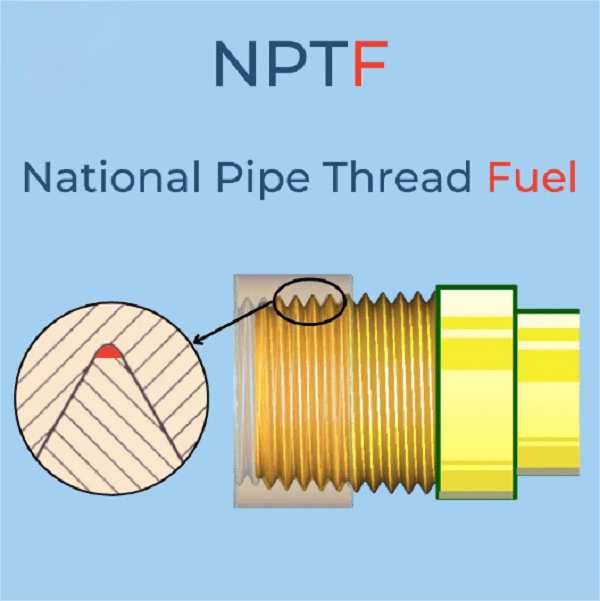

3. What is NPTF?

NTPF or National Pipe Taper Fuel is a type of thread form that is used with another part to make a taper thread seal without any need for any sealing material.

Another name for NPTF threads is Dryseal threads; these threads have the same taper angle and thread pitch as those of NPT threads but have changed crest and root profiles.

These changes enable the threads to change their shape slightly when tightened to make a metal-to-metal connection.

NPTF threads conform to the American National Standards Institute/American Society of Mechanical Engineers, B1.20.3 standard and are suitable for use where leak loss must be controlled, but thread seal cannot be achieved using thread sealants.

This characteristic is especially valuable in industries employing fuels, oils, and other sensitive fluids.

4. NPTF Application

These NPTF threads have been designed to suit specific needs and offer high sealing integrity. Common uses include:

- Fuel Systems :NPTF threads are typically utilized on fuel lines and fittings where leakproof connectors are required, but sealants are impossible.

- Hydraulic Equipment: High-pressure hydraulic systems use NPTF threads for dry seal connections because they are reliable.

- Pneumatic Systems: NPTF threads are admired in air compressors and all other pneumatic tools due to their self-sealing nature.

- Oil and Chemical Industries: NPTF threads are most suitable for fluctuating or dangerous fluid leakage.

- Aerospace Applications: Because of their excellent sealing capability, NPTF threads are applied in aircraft fuel and hydraulic systems.

NPTF threads can make a dry seal, so they are used in situations where other sealing materials may pollute the system or affect performance.

5. How to Choose NPT or NPTF for Your Application

Some applications require NPT threads, while others require NPTF threads – albeit with different thread dimensions. Here are some factors to consider:

- Sealing Needs: If your application allows you to use sealants or tapes, NPT threads are much more affordable and quite versatile. NPTF thread is preferred when a system demands a dry seal.

- Fluid Type: For critical applications or fluids, like fuels and chemicals, NPTF threads provide further reliability without the necessity for sealers.

- Pressure Levels: NPT or NPTF threads can both be used for pressure systems, but NPTF threads have a dry seal, which is used in critical pressure systems.

- Industry Standards: Find out if there are guidelines on the appropriate thread types in your industry. For instance, some specific industries, such as aerospace and chemical, may require NPTF threads because they are safer.

- Cost and Availability: NPT threads are more easily procurable and cheaper. However, because NPTF threads are specialized in some particular forms, they may be useful to some clients and allow them to pay higher costs.

You can select the right type of thread by examining your system's sealing, fluid, and pressure demands.

Conclusion

It is vital to comprehend the two types of threads, NPT vs NPTF, in order to get the best outcome for the application.

Although NPT threads are generic and familiar, they are generally not self-bedding and are always used in conjunction with other sealing media.

On the other hand, the NPTF has a dry seal thread with minimum leakage, which makes it suitable for those critical areas.

Therefore, the sealing, pressure, and fluid assessment of your application results in making the right choices in an informed manner whilst achieving all aspects of a safe and efficient piping system.

Our Armpre Machinery can provide customized thread rolling machines and electric tapping machines to meet your NPT or NPTF Threads products requirements

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024