How To Choose a CNC Lathe? Teach You Step by Step

Introduction

CNC (Computer Numerical Control) lathes employ computer programming to direct the planned movements of the cutting tools and the machining piece. CNC cutting materials, including such as steel, aluminum, titanium, brass, copper, stainless steel, and plastic, with unbelievable accuracy contrary to manual lathe。

This automation enables quicker, precise, and replicable production, which makes the CNC lathes a core in the Automotive Industry, Aerospace, Mold Manufacturing, Medical Devices, Electronics, Machinery Manufacturing, Defense Industry, Shipbuilding Industry, Energy Sector, and Home Appliance Manufacturing

Due to the desire of industries to have improved productivity and smaller tolerances, the need for CNC lathes has increased. Such machines are very vital to any company that intends to remain competitive since they minimize errors made by human beings, minimize production time, and those that have a complex the design.

A CNC lathe may be used in small workshops or big factories to convert the raw materials to finished products with little wastage, thus saving time and money. The proper selection of a CNC lathe is, however, vital in making sure that it satisfies your particular requirements, whether you are a recreational enthusiast or a manufacturer on an expansive scale.

Browse through a number of CNC lathes, and choosing the right one may be daunting. Such criteria as size and power, features, and budget contribute to the inventorying as well. Herein, we will guide you through everything you need to know about CNC lathes, their components, mechanisms, functions, and how they work, and help you choose what to purchase step by step.

1.What is a CNC Lathe Machine?

A CNC lathe machine is an automated machine that is controlled by a computer to turn and shape materials by spinning the workpiece against the tools.

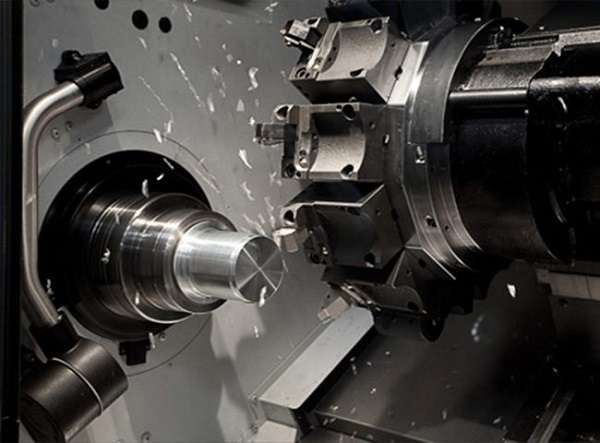

The piece being worked is usually a piece of material that is cylindrical, rotates at high speeds with the tools cutting out material resulting in the specific desired shapes, e.g., rods, screws, or ornaments.

The CNC describes a computer system that guides the activities in the machine through programmed set instructions to make accurate adjustments to the fractions of a millimeter.

Unlike in manual lathes, where the operator uses his hands to manipulate the tools used, CNC lathes depend on software to determine every movement. This can be used to produce complex designs consistently, even when thousands of parts are made.

Its sizes vary as there are small ones that fit on the desktop and are more dedicated to hobbyists, and large ones that are industrial and used to produce in large amounts.

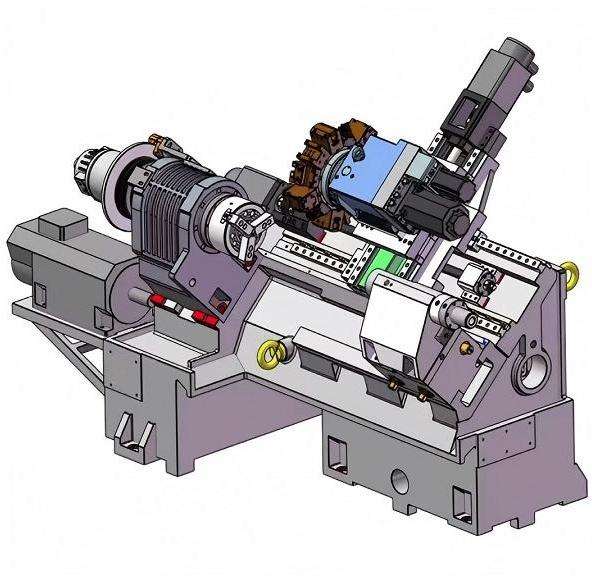

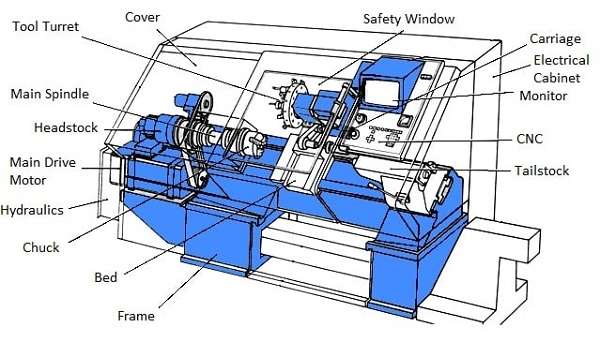

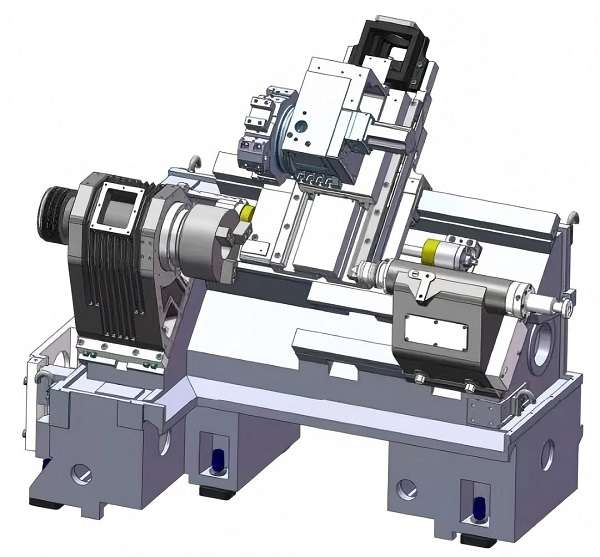

2.The Different Parts of a CNC Lathe

A CNC lathe is an elaborate machine comprising a number of essential parts, all of which are crucially involved in its functionality.

Knowledge of these components and their specifications is most important when deciding on a CNC lathe because they dictate what the machine is capable of doing- the size of the workpiece it can process, the precision it gives, and the kind of material it is capable of processing.

Other specifications, such as spindle speed, power, and bed size, are critical considerations as they determine performance and the desired application. Now we will see the significant parts of a CNC mill.

CNC Control system

The numerical control (CNC) system controls machining equipment through a computer, enabling a high-precision and automated manufacturing process. Well-known brands include:

- FANUC

- Siemens

- Mitsubishi Electric

- Haas Automation

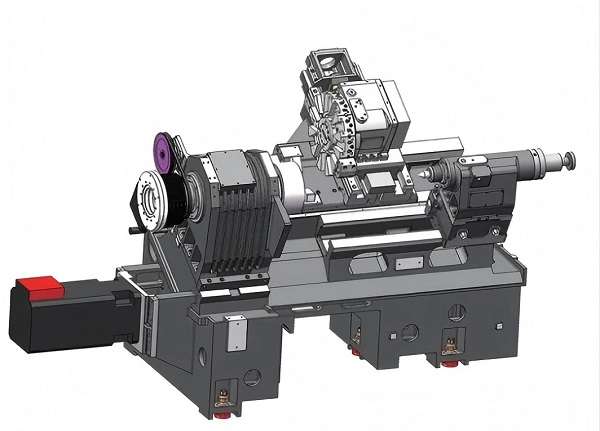

Machine Bed

- Function: The machine base is made of cast iron, providing stable support for the CNC lathe and reducing vibrations to ensure operational precision.

- Material: Typically made of cast iron for durability and vibration dampening.

- Importance: A sturdy bed ensures precision by minimizing vibrations during operation, which is critical for maintaining tight tolerances.

- Considerations: Check the bed length, as it determines the maximum length of the workpiece you can machine.

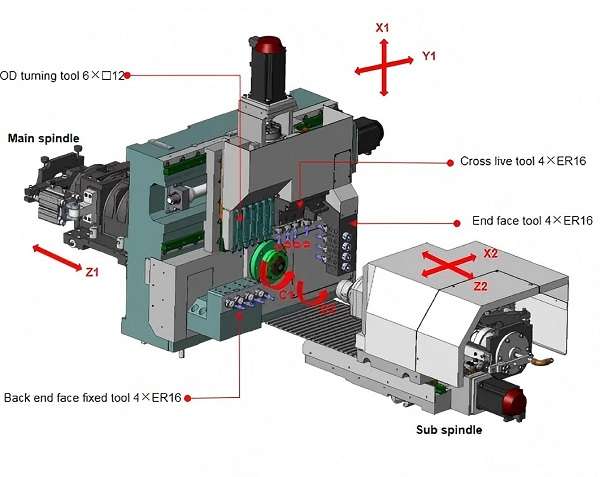

Main Spindle

- Function: The spindle is the core component of a CNC lathe, driven by a motor to rotate the workpiece at high speeds. Its variable speed operation directly affects cutting efficiency and surface quality.

- Features: It’s powered by a motor and can operate at variable speeds, depending on the material and task.

- Importance: The spindle’s speed and power affect cutting efficiency and surface finish quality.

- Considerations: Look for spindles with adjustable speed ranges and sufficient horsepower for your materials.

Sub-Spindle/Second Spindle

- Functions: The sub-spindle allows machining on both sides of the workpiece without repositioning, enhancing the efficiency of complex CNC lathes.

- Features: Can be commonly found in complex CNC machining lathes since it maximizes efficiency due to continuous machining.

- Usability: It is applicable to complex parts that need working on both sides, which saves set-up time.

- Considerations: When your projects will involve parts of a CNC mill that are multi-sided or fine enough in detail that accuracy is a significant problem, then a sub-spindle can make such jobs more economical and lead to better accuracy.

Headstock

- Function:The headstock secures the spindle and connects to the machine base, housing gears and bearings to support the spindle’s rotation.

- Contributions:Has gears and bearings to help facilitate the spindle's rotation.

- Significance: The headstock is where the spindle rotates, so it must be strong to make sure there is less friction and wear and tear.

- Factors to note: Be sure that the headstock is reinforced to provide the best spindle performance and durability.

Tailstock

- Function:The tailstock supports the other end of the workpiece, preventing bending and can be adjusted according to the workpiece length to support the tool.

- Capabilities:Can support tools such as drills or can be adjusted along the bed when dealing with different lengths of workpieces.

- Significance:Long workpieces are stabilized and precise at a significant level.

- Issues to consider:Spruce the features on the tailstock; get a programmable or hydrated one.

Collet and Chuck

- Function:The collet is used for high-precision clamping of small cylindrical workpieces, while the chuck is suitable for larger or irregularly shaped workpieces.

- Collet: A narrow sleeve holder of smaller and cylindrical work pieces that are held with high precision.

- Chuck: A clamping device that has jaws that are perfect for handling large or irregular-shaped workpieces.

- Significance:A collet or a chuck must be selected depending upon the size and shape of the workpiece.

- Considerations: Make sure it is compatible with your workpieces and ensure quick change systems are provided to promote efficiency.

Carriage

- Function:The carriage holds and moves the cutting tool, equipped with a turret and cross slide to ensure precise tool positioning

- Contribution:Has the tool turret (which contains the multiple tools) and the cross-slide (used to fit the tools precisely).

- Significance:The smooth movement is essential in the precise cutting and finishing of the carriage.

- Factors to Consider: Prioritize a carriage with a sturdy tool turret and smooth guide ways to provide dependable results.

3.How Does a CNC Lathe Machine Work?

A CNC lathe is a machine that works based on the rotational movement of a piece of work and the removal of material by a tool to create a shape. A digital design is made first with the help of CAD (Computer-Aided Design) software.

CAM software converts this design into a set of instructions, i.e., G-code. The G-code gives the CNC lathe specific information on how to move the workpiece and tools.

After the G-code has been uploaded to the lathe, the operator fastens the workpiece in the chuck or collet. The spindle rotates the workpiece at a fixed speed, and the work is done by the carriage, which moves along the X and Z axes (horizontally and longitudinally).

The computer accurately guides the tool path, speed, and depth of cut such that when the toolpaths are rendered on the computer, the final part is an exact rendition of the digital design.

Sensors and feedback mechanisms will monitor the procedure and make real-time corrections to ensure accuracy.

On high-end CNC lathes, options such as live tooling or a sub-spindle are available to permit various other operations, such as drilling or milling, to be done to a workpiece without having to release it.

The automation would save human intervention to a minimum, assure fewer errors, and the production would be faster; hence, CNC lathes are very proficient in both large and small-scale production.

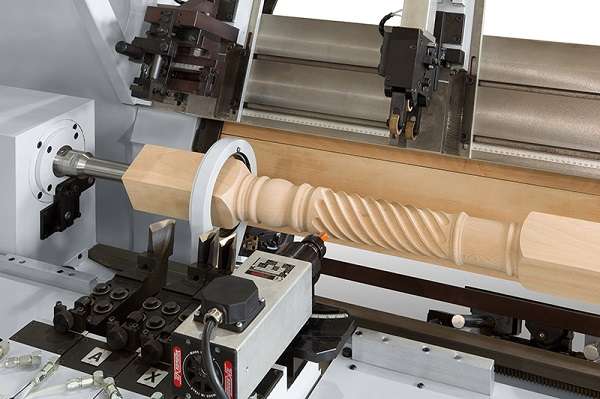

4.What Operations Can Be Done with a CNC Lathe?

CNC lathes can perform a variety of operations. Following are the most frequent tasks they may process:

- Turning:Wet turning is the most critical process, in which there is rotation of the workpiece and removal of the material to produce cylindrical objects such as shafts and tubes.

- Facing: Leveling the end of a piece to give a smooth, even surface.

- Drilling:Machining a hole-shaped workpiece by using a drill mounted in the tailstock or one of the tool turrets.

- Boring:To size previously drilled holes to specific diameters in order to achieve better precision and finish.

- Threading:Removal of threads (internal or external) to form the screws or bolts.

- Knurling:Raising a pattern of knurling on the surface of the work done to give better purchase, commonly used on tool handles.

- Grooving:Making a deep cut in the shape of a groove, usually to fit O-rings or as a decoration.

- Parting/Cutting Off: Cutting the completed part off the raw material.

- Taper Turning: Tapering of the workpiece by gradually decreasing the diameter.

- Milling (Live Tooling): CNC lathes with live tooling are also able to mill (create a slot or part flat surface) without having to move the work to another machine.

Automatic change of tools and the possibility of carrying out several operations in a single setting increase their efficiency.

5.In Which Applications Are CNC Lathes Generally Used?

CNC lathes find use in a vast industry as they are precise, versatile, and more importantly, capable of producing complex parts excellently and with great speed.

Whether it is making complex parts of high-tech equipment or the production of sturdy parts of heavy machine equipment, CNC lathes are an essential means of modern-day production.

Some of the main applications of CNC lathes are outlined below, and they include foundry activity and military work.

Foundry Production:

What is a foundry? A foundry is an establishment where raw resources, usually metal such as steel, aluminium, or iron, are melted and poured into molds of desired shapes.

Such castings typically need to be refined further to acquire the desired levels of accurate dimensions and smooth surfaces, and it is here that CNC lathes enter the picture.

Use in foundry: CNC Lathes castings are turned into accurately machined products through the capability to bore and thread to the specifications required.

As an illustration, they are able to machine cast engine blocks, pump housings, or valves, among others, and have very controlled tolerances and quality finishes.

CNC lathe machines increase the number of parts that the foundries are capable of processing, especially with a high level of consistency, as it eliminates the manual labour needed in the process.

Advantages: CNC lathes operate on more difficult materials, such as cast iron or stainless steel, often used in foundry processes, and are able to manage more complex geometries than manual lathes.

Military Applications:

In the military industry, CNC lathes play an essential role in the manufacture of high-precision parts that are classified for use in weaponry, automobiles, and aerospace equipment. The examples are missile casings, gun barrels, and plane landing gear parts.

CNC lathes have a high degree of precision, and thus military parts remain highly precise in terms of safety and their functionality.

As an example, threading ammunition components or turning titanium fighter jet parts are exact applications that CNC lathes can fulfill with repeatability

They are essential because of their mastery of high-end materials such as titanium, composites, and high-strength alloys, needed to produce military products whose durability and precision are never compromised.

Other Applications:

- Automotive Industry: CNC lathes create diesel engine, automobile parts, shafts, and fittings with high accuracy in cars, motorcycles, and trucks.

- Aerospace: Aerospace is employed in the fabrication of the turbine blades and landing gear components, among other parts, where intricate tolerances and lightweight materials are necessary.

- Medical Industry: CNC lathes produce surgical equipment, implants, and prosthetics out of biocompatible materials such as stainless steel or titanium.

- Electronics: They manufacture connectors, housings, and other small, fine components of electronic devices.

- Oil and Gas: CNC lathes manufacture fittings, valves, and drilling accessories that are able to sustain rigorous conditions.

6.What Types of CNC Lathe Machines Are There?

CNC lathe machines are designed as subtypes, and are intended to handle special purposes, part size, and complexity.

Your choice of CNC lathe will be determined by the precision and flexibility requirements, together with the production needs of your projects. There are three main types of CNC lathes described below by their axis functionality and system design.

2-Axis CNC Lathe:

Description: The easiest form of which has two linear axes (X and Z). The horizontal movement of the tool is controlled by the X-axis, and the longitudinal movement on the workpiece with the help of the Z-axis.

Applications: Suited to low-end turning such as cylindrical machining, facing, and threading.

Benefits: Cheap, convenient to program, simple parts.

Considerations: Restricted to simple operations; not applicable in situations that demand multi-angle machining of complex shapes.

3-Axis CNC Lathe:

Description: Provides a third linear axis (usually Y or a live tooling axis) to permit more complicated operations such as milling or off-center drilling.

Applications: It is utilised where the part needs like slots or inclined holes in the part, without reorienting the workpiece.

Pros: It is more flexible than 2-axis lathes with a somewhat simple operation.

Considerations: A little higher priced but a good cut off at small to medium workshops.

4-Axis CNC Lathe:

Description: This one has an extra rotational axis (usually C-axis, which controls the rotation of a spindle), allowing more sophisticated machining tasks.

Uses: Handy with features on more than one side, e.g., gears or components that are to be milled off-axis.

Pros: Multi-sided parts become flexible and have reduced setting time.

Considerations: More complicated degree of skills and a greater level of investment.

5 Axis CNC Lathe:

Description: Introduces an additional axis of rotation so that the tool or workpiece can tilt and rotate and perform detailed operations.

Applications: Aerospace and medical industries for complicated components such as turbine blades or orthopedic implants.

Pros: Can machine with a high degree of complex geometries within one setup with greater accuracy and efficiency.

Considerations: Costly and specialized operators are needed, as well as sophisticated software.

CNC Lathe 6 or More Axis:

Description: The machines are highly advanced with six or more axes, which provide the maximum flexibility to be used in multitasking.

Uses: In high precision manufacturing where components need to be machined simultaneously on multiple axes, e.g., in aerospace or prototyping.

Strengths: Able to process complete parts within a single setup and reduce handling and errors.

Desirable features: Extremely expensive and intricate; suited to mass and high-resolution production.

Vertical CNC Lathe:

Description: It is vertically spun with the tool above the workpiece. Gravity aids in affixing the workpiece.

Applications: Suitable when there are heavy, large-diameter workpieces such as wheels, turbine disks, or large castings.

Benefits: It is easy to place heavy components in it, and it can be used to carry out large-scale production.

Considerations: Uses a larger footprint on the floor, and small, detailed parts may be problematic.

Horizontal CNC lathe:

Description: The spindle is flat, and the workpiece is lifted up parallel to the ground. This is the most elementary CNC lathe machine.

Applications- a variety of different parts can be used, including small screws, long shafts, and other applications in various industries.

Pros: Adaptable, easy to find, and can be used in most turning applications.

Considerations: Maybe need extra support with a workpiece of very long length to keep it from being deflected.

Swiss-Type CNC Lathe:

Description: Used for small-diameter high-precision parts. A guide bushing is used to hold the workpiece, and long, slender parts can be machined accurately.

Applications: Watchmaking, medical equipment manufacturers, and electronics manufacturing often use them to make parts, such as screws or connectors.

Benefits: Great accuracy in small work and less wastage of materials.

Considerations: Suitable for prominent volume manufacture of small parts.

Multi-Spindle CNC Lathe:

Description: Has multiple spindles so as to machine several workpieces at once or multitask simultaneously.

Uses: Created in large-scale manufacture of items such as automotive fittings or fasteners.

Benefits: Improves throughput and decreases cycle times.

Considerations: Intricate installation and is more expensive; it is adapted to large-scale production.

B-Axis CNC Lathe:

Description: Has a B-axis to rotate the tools, so that inclined machining instructions and complex contours are possible.

Applications: Intricate castings in the form of aerospace or moulds, where tools must be angled at more than one point towards the workpiece.

Pros: Improves complex geometry flexibility and multitasking.

Cons: More costly, needs to be known with advanced programming.

7.What Are the Top 10 Recommended CNC Lathe Manufacturers?

What is a CNC lathe machine’s manufacturer’s importance? By choosing a quality CNC lathe manufacturer, you will select a machine that will provide the type of production you require and future benefits. The list below contains the top 10 recommendations regarding CNC lathe manufacturers, who are all known as the most quality, innovative, and reputable in the industry.

- Mazak: A Worldwide market competitor that provides multitasking CNC lathes, applicable to all industries, e.g., in automobile and aerospace engineering, their machines are high-scoring and accurate.

- DMG MORI: It will blend German and Japanese skills and produce versatile lathes which are used in high-end manufacturing, usually with innovative automation and high precision.

- Haas Automation: Offers inexpensive, dependable CNC lathes, mainly in the small to medium shops, and pays much attention to easy-to-use controls.

- Okuma Corporation: Recipe of high-quality, long-lasting precision lathes with excellent CNC Systems commonly used in heavy industries such as oil and gas.

- EMAG Group: First movers in inverted lathes and combined automation, and a leader in high production automotive and aerospace component manufacturing.

- Hardinge Inc.: Very high precision lathes, leader in small to medium turned work in military and medical markets.

- Doosan (DN Solutions): Has high-rigidity lathes with global supports, which are ideal for strong toughness in automobiles and general engineering.

- Citizen Machinery: Deals in CNC lathe machines of the Swiss-type and provides high precision in small and complex productions in the medical and electronics sectors.

- Nakamura-Tome: Offers precise, dependable lathes with easy-to-operate controls and is suited to machining demanding parts and parts with high accuracy standards.

- Tsugami Corporation: This is a leader in precision Computer Numerical Control (CNC) lathes (especially Swiss-type), serving industries that need micro-sized, high precision parts.

8.What Factors Should We Consider Before Purchasing a CNC Lathe?

Selecting the appropriate CNC lathe you require should consider a number of essential factors so that it fits well within your production, budgetary, and operating needs. The following are some considerations to help you make an informed choice.

Certifications:

Seek ISO Certifications (e.g., ISO 9001:2015) as a quality management standard, CE Marking to adhere to the European safety standard, UL Certification to adhere to the electrical safety standard, RoHS Compliance to adhere to environmental requirements, and ASME Certification as a pressure vessel or mechanical requirement.

Certifications show that the machine complies with the regulations in the industry, making them reliable and safe for your operations.

Parts Materials:

Make sure that the lathe is able to work with a variety of materials such as: steel, aluminum, copper, stainless steel, titanium, and bronze, because such materials are standard in many industries such as automotive, aerospace, and medical.

To be on the safe side, ensure that the machine is compatible with the kind of hardness of the material and the requirements of the machining processes.

Max Size of Parts (Length and Diameter):

Confirm the maximum capacity of the length and diameter of workpieces in the lathe. Saying this is applicable to the degree that small lathe types can process parts to 300 mm in diameter, whereas an industrial model would have the capacity to process over 1000 mm.

Select a machine that will fit your most significant parts both now and in future projects.

Machine Power:

Determine the power of the spindle motor (e.g., 5-30 kW on industrial models, 600 W on desktop models) to verify that it is adequate to cut your materials and meet your cutting needs.

Heavy-duty materials such as titanium or large-scale production require higher power.

Working Efficiency:

Measure the cycle time (time required to produce 1 part), feed rate (the speed of the tool motion, usually 10-40 m/min), cutting speed (the spindle speed, e.g., 1000-6000 RPM), tool change time (e.g.1-5 seconds with ATC), machine utilization (percentage of time the machine is running or idle), and take time (production rate at each step to meet demand).

When cycle times are faster and utilization is higher, the throughput is increased, particularly in high-volume production.

Machine Accuracy and Repeat Accuracy:

Seek machines with accuracies and repeat accuracies of up to +0.01 mm or +0.001 mm, as required in such businesses as aerospace or medical, where precision is key.

More accuracy will guarantee uniform part quality that cuts down rework and wastage.

Machine Stability:

Find features such as high-quality iron beds, precision bearings, and thermal compensation systems to dampen vibration and help provide stability at high speeds.

Consistent precision with tools and prolonged tool life is achieved in stable machines.

Support Automation:

Automatic Tool Changers (ATC) for quick ingoing and outgoing tools, robotic loading and unloading for a free-hand operation, part handling systems for efficient management of workpieces, software automation for smooth programming.

Automation is cheaper in labor costs and more efficient, especially in high-volume environments.

Local Voltage:

Make sure that it can work with your facility power supply: single phase 110-120V or 220-240V on smaller ones, three phase 380-415V or 480V on industrial forms, or custom voltages such as 230V or 600V on custom installations.

Confirm electric requirements to prevent unnecessary electrical alterations.

Machine Safety:

Search factors such as emergency stop buttons, guarding to keep the operators safe, and the suggestive use of personal protective tools such as goggles and gloves.

Strong safety provisions make it less likely that various accidents will arise at work and ensure that the regulations are adhered to.

CNC System:

Select a dependable control system such as Siemens, Fanuc, GSK, SMARTBRAIN, or Haas. Fanuc and Siemens are great in reliability/ease of use, and Haas has easy interfaces in smaller shops.

Your CNC system must fit the skills in your team and programming requirements.

Warranty:

Ask for at least a 2-year parts and labor warranty and read the exclusions (e.g., wear-and-tear parts or abuse). One that has a wide coverage of a warranty minimizes future maintenance expenses.

Find out whether it has on-site coverage or if there are replacement components involved in the warranty.

After-Sale Service:

Check installation support and commissioning support, sources of technical support (e.g., 24/7 phone or online), maintenance services, spares availability, operator training and support resources, upgrade potential, and customer feedback on customer service quality.

Good post-sale services also provide a low level of downtime and long-term reliability.

Machine Cost:

Compare prices between manufacturers based on initial purchase price and long-term value. Use manufacturer websites (e.g., www.mazak.com, www.dmgmori.com, www.haascnc.com) to obtain pricing information on specific products.

Weigh cost against features, because cheaper machines may be less accurate or more fragile.

Conclusion

The world of CNC lathes might be confusing, and it might start to appear overwhelming; however, with the proper knowledge, you can make a confident decision to choose a machine that can take your production to a new level.

Doing your research on the best manufacturers, such as Mazak, DMG MORI, Haas, and closely analyzing their role in certifications, material compatibility, automation capabilities, along with customer post-sale services, can help you meet the ideal CNC lathe machine that best suits your needs.

Spend the time to match your selection to your own applications, be it foundry production, military manufacturing, and so on, and focus on quality, precision, and efficiency.

Based on the key points just explained to you, I believe you can make a rational choice for a CNC lathe that can meet current production needs and has long-term investment value. Of course, you can also visit the manufacturer's official website (such as https://armpremfg.com/ )Get the latest customized solutions.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?

Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines: The Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling Milling Machine: The Ultimate Buying Guide in 2024

- CNC Tapping Machine: The Complete Buying Guide in 2024

- Pipe Chafering Machine: The Complete Importing Guide in 2024

- Radial Drilling Machine: The Complete Buying Guide in 2024

- Thread Rolling Machine: The Complete Buying Guide In 2024

- Pillar Drilling Machine: The Ultimate Buying Guide in 2024