How To Choose A CNC Milling Machine for Your Metalworking?

Introduction

The decision to select the right CNC milling machine is an important process for any person in the metalworking industry, whether you are operating a professional shop or busy DIYing.

There are numerous types of such machines of a large variety to choose from, differentiated in terms of their size, speed, precision, and capabilities. It is possible to feel lost when selecting the one that suits your particular needs.

The right selection of a CNC milling machine can guarantee productivity, ensure regular precision, and process delicate metallic components with ease.

In this guide, we will take you through the critical factors that can guide you in choosing the ideal CNC milling machine to meet your metalworking needs.

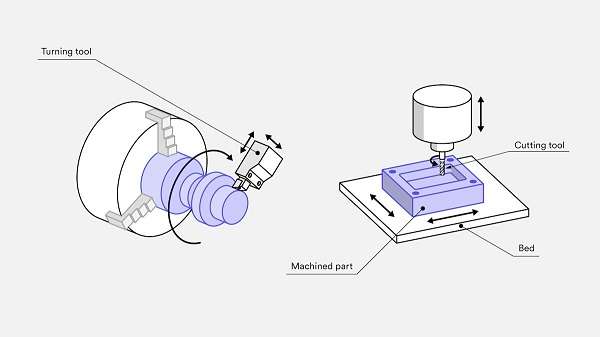

1. What is a CNC Milling machine?

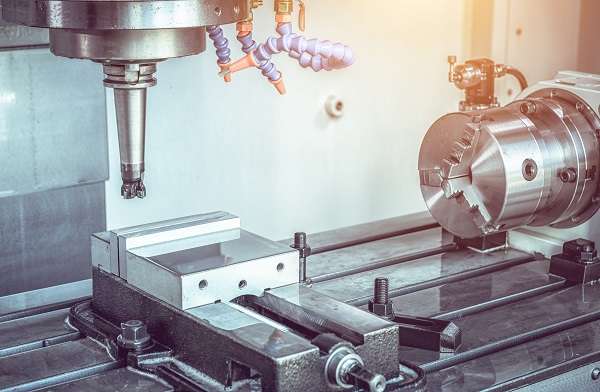

A CNC milling machine is a Computer Numerical Control (CNC) machine that involves removing material and forming pieces by rotating cutting tools, which are shaped to impart precision to workpieces.

By the standard milling machine definition, the machine is capable of producing quality parts with a smooth finish on its surface.

As an example, the CNC milling machine 33100 is understood to be one of the stable models to work with precision machining, although the CNC machine 368000 is more suitable when it comes to mass production, as it can deal with creating complex metal and plastic components in large volumes.

These machines use the programmed computer codes, and there is no necessity for human intervention involved; hence, the efficiency, consistency, and productivity are more, and therefore they have become irresistible in the manufacturing industry today.

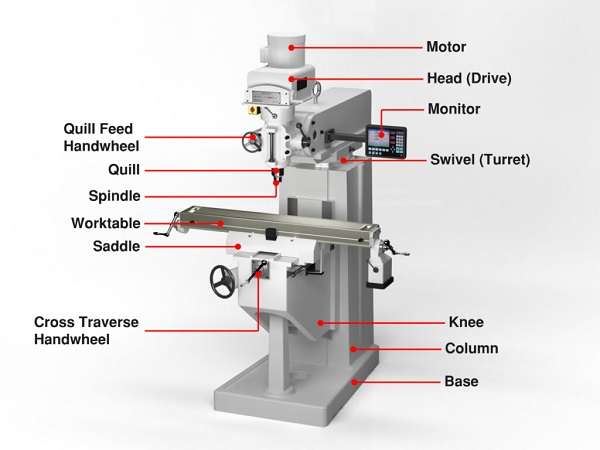

2. The main components of a CNC Milling Machine

To achieve high-precision machining, the fundamental CNC milling machine parts 880 need to be known. These parts are stabilized, precise, and work effectively in multifaceted milling operations. The major milling machine parts 2900 are given below:

- Control System:This is the main machine that guides and controls all the other machines with precision because it has already been pre-programmed.

- Knee:A vertically movable component that is attached to the column. It holds the slide and the table and enables them to move vertically on the Z-axis to regulate depth.

- Column:The column supports the skeletal portion of the machine and acts as the base where the mechanical apparatus in the machine is housed.

- Slide (Saddle):The slide is placed between the knee and table, and moves horizontally along with the spindle, which makes it possible to accurately position the workpiece.

- Table:The table that contains the workpiece sits at the top of the slide. It can move in various directions, depending on the milling operations.

- Spindle:An important rotating shaft is powered by a motor. It carries the cutting tool, and it is the one that does the actual milling.

- Axle:This is common in a horizontal mill, where it is added into the spindle to accommodate different cutting tools.

- Machine Tool:It is a cutting tool in the hands of the spindle that cuts material away from the workpiece. Each of them is employed in different kinds of milling.

The collaboration of these milling machine parts and CNC parts is essential for offering the modern machining precision, repeatability, and productivity.

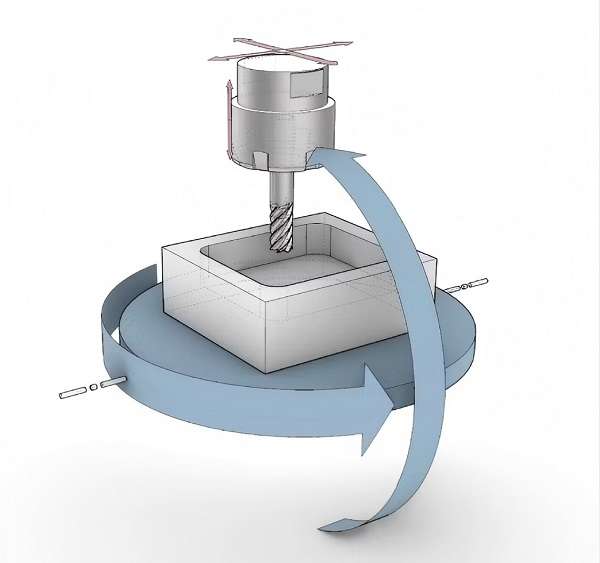

3. How Does a CNC Milling Machine Work?

A CNC milling machine operates based on an accurate directive whilst operating on a CAD file, which entails the specific shape and size of the part to be manufactured.

With CAD-based CNC production, the digital design is generated and made ready to be produced with CNC. This is subsequently uploaded to CAM software programs, which translate it into CNC milling machine programming 1300, usually in G-code format.

These directions dictate the movement of tools on different axes on the machine in order to provide sophisticated and precise milling activities. A proper CAD file 12100, trusted CAD software for CNC 220, and effective programming of the CNC milling machine yield precision in prototype making and mass production.

4. What operation can be done with a CNC Milling Machine?

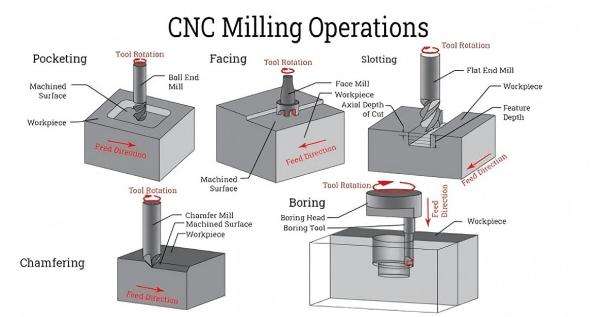

A CNC milling machine can do a lot of different things with accuracy and speed. Common techniques include:

- Vertical Milling 1900:The spindle is set in vertical orientation in this operation. Perfect for precise cutting, drilling, and slotting of the flat surfaces.

- Horizontal Milling 6600:The spindle has a horizontal composition, which allows thicker, more profound cuts and a large cut rate of the material.

- Face Milling 6600:Applied to the work of machines on flat surfaces. The edge of the cutting tool is at a right angle to the surface to get smooth and clean finishes.

- Plain Milling 720:This is also referred to as surface milling, whereby material is removed using a cutting tool parallel to the surface of the workpiece, ideal in grooves or flat faces.

- Angular Milling 210:This work is done by machining the angles or bevels by orienting the tool at a definite angle to the working piece.

- Form Milling 390:Uses special-shaped knives to cut multi-shaped contours, curves, and irregular profiles on the workpiece.

The adaptable functions of these types of machines predispose CNC milling machines to a broad variety of manufacturing pursuits.

5. What are the tools used in CNC milling machines?

The use of a CNC milling machine depends on the variety of cutting tools to undertake precise and complex machining duties. End Mills can also be profiling, slotting, and contouring.

The Face Mills are precision tools used in machining big and flat surfaces. Ball Nose Mills are perfect to make curves, intricate 3D surfaces, and contoured parts. Reamers are particularly employed to complete and expand holes, pre-drilled but with high precision.

Taps remove internal threads to have fastening holes. There is also the use of Specialty Tools in the event of special or tricky tasks that normal tools cannot take care of. In total, this equipment turns CNC milling into one of the most versatile processes and the one that can be used to create a complex part.

6. Which applications are CNC milling machines generally applied to?

Milling having CNC can be placed in great use as far as the manufacture of components of an engine, as well as the transmission systems in the automotive industry, and precision parts on aircraft in the aerospace industry.

They are used in mold manufacturing to come up with precise molds and dies. They manufacture implants and surgical tools in the field of medicine. The electronics industry takes advantage of highly precise housings, and the machinery manufacturing industry produces gears and machine parts.

CNC is used in the defense industry to generate weapon parts, the shipbuilding industry to produce propellers, the energy sector industry to generate turbines, and home appliances manufacturing to introduce precision-fitting parts to guarantee quality and consistency in the applications.

7. What are The Different Types of CNC Milling Machines?

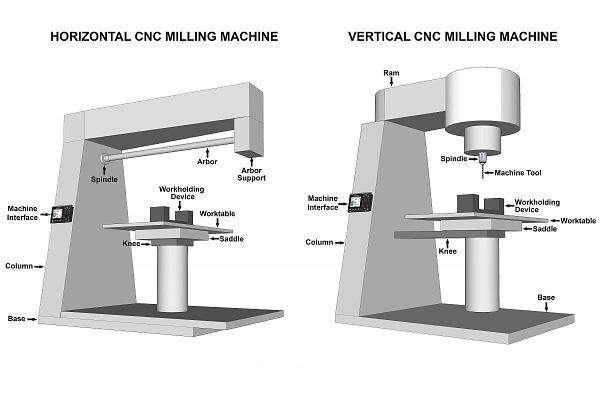

· Vertical Milling Machine 6600

A Vertical Milling Machine has a vertical position of its spindle, suited to friction tasks characteristic of cutting, drilling, and shaping. It finds common application in small to medium-sized workpieces.

· Horizontal Milling Machine 6600

A Horizontal Milling Machine is characterized by the horizontal spindle itself, which enhances the disposal of the chips, and it is especially convenient to work with heavy-duty cuts and larger parts.

· Horizontal Vs Vertical Milling Machine 320

The preference of the two is dependent on the production requirements: vertical production needs precision and versatility, whereas horizontal production needs power and volume.

· Multi-Axis CNC Milling Machine

A 2-axis CNC milling machine 40 has just two axes of movement, whereas a 3-axis CNC milling machine 880 has three. The advanced types feature a 4-axis milling machine 170 to perform rotary operations and a 5-axis CNC milling machine 590 to perform complex and complex geometrical work with precision.

8. Top 10 Recommended CNC Milling Machine manufacturers

· Hass CNC Milling Machine 1900

Haas Automation is one of the largest manufacturers known to produce a wide variety of CNC milling machines.

Haas machines are associated with durability, precision, and easy-to-use controls, and work in both small shops to large-scale manufacturing. They are used all over the world due to their flexibility.

· Mazak CNC milling machine 320

Mazak provides high-tech solutions involving high-speed machining and accuracy in milling. These machines are suitable for high production settings, where quality and efficiency are key, with great reliability.

· DMG Mori CNC Machine 720

DMG Mori is an experimental technology company that delivers high-quality CNC milling machines because of its precision engineering. The DMG Mori machinery is renowned in the industry, cutting across the automotive, aerospace, and medical industries.

· Siemens CNC Milling Machine 40

Siemens offers CNC milling technologies that are highly tailored and well acquired using powerful software. They can be used in a variety of machining applications: prototypes and production-scale-up.

· Fanuc CNC milling machine 210

Fanuc has some of the most powerful yet reliable CNC milling machines that have high automation capabilities. Industries using their systems abound in the aspects of speed, accuracy, and long-term functionality.

· Okuma CNC Milling Machine 40

Okuma manufactures high-performance CNC milling machines that are precise and efficient. The machines have an accurate mixture as they are designed to handle difficult and demanding machining functions.

· Makino CNC milling machine 50

Makino focuses on the high-speed machining technologies whereby the equipment manufactured can withstand complex part manufacturing processes. Their machines have been popular in the manufacture of aerospace, dies/molds, and medical devices.

· Hurco CNC Milling Machine 880

Hurco is lauded as a company that produces versatile CNC milling machines that are easy to operate. Hurco machines are the performance/friendly curve blend suitable for prototyping and small-volume manufacturing.

· Bridgeport CNC Milling Machine 320

Bridgeport has the reputation of reliability and a long record in vertical milling machines, in particular. Solidly built and simple in usage, they have long been a reliable brand of machining.

· Toshiba Milling Machine 20

Toshiba Machine provides quality milling services that are produced with the best engineering standards. They make their machines to suit the industries that need uniform precision and innovation during machining.

9. Check Points on how to buy a suitable CNC Milling Machine for your work

Making the right decision in regard to your choice of the CNC milling machine is essential in obtaining productivity, accuracy, and long-term sustainability of your manufacturing facility. The following are factors you need to look into prior to realizing your investment.

· Define the Standard or Application

To begin with, it is important to explain the point of the CNC milling machine. Is it to be in precision prototyping, heavy-duty production, or to make intricate molds?

Comparing the features of the machine to the one you want to have will help you achieve the best performance out of it, and efficiency will be achieved.

· Number of Axes

Choose between a 3-axis and a 5-axis CNC milling machine.

- 3-axis machines will work best with simpler machining and general-use work.

- The more complex geometries adaptable into 5 concurrent machines mean that multi-sided machining may be done in one arrangement, saving time and producing predictable precision.

· Machine Size

Select the size depending on the largest dimensions of the components that you are going to machine. Bigger components are supported by a larger work envelope, and a small machine saves space and cost on smaller projects.

· Machine Certifications

Make sure that the CNC milling machine meets the world's quality and safety standards. Armpro CNC Milling Machines can be supported with the ISO Certifications, CE Marking, UL Certification, RoHS Compliance, and ASME Certification, so there is certainty in quality, safety, and compliance.

· Accuracy

Precision manufacturing depends on accuracy. To perform tight-tolerance work, seek out machines that have a positioning accuracy and repeatability in the 0.01mm to 0.001mm range.

· Material Compatibility

Select a CNC milling machine that can operate with different types of materials, including steel, aluminum, copper, stainless steel, titanium, and bronze, making it versatile, adaptable, as well as capable of satisfying the diverse needs of different clients in different industries and even in complicated machining applications.

· Machine Voltage

Armpro CNC Milling Machines are addressed in the standard three-phase voltage 380-480V, but other voltage options can be used, including 230V or 600V, to suit the needs of specific countries.

They must be compatible with the standard of the power supply in your facility, or else you will incur some expensive adjustments.

· After-Sales Support and Service

An excellent supplier ought to provide complete after-sales service. Armpro offers installation and commissioning, technical support, maintenance, spare parts, training, upgrade, as well as customer feedback.

· Warranty

Armpro has a 2-year parts warranty, and that should show confidence in quality and peace of mind.

Such insurance lowers sudden expenses caused by repair, facilitates steady production as well, and ensures constant support of your CNC milling machine investment, making your investment in the CNC milling machine more secure and economical.

· Machine Parameters

Test major parameters like:

- Power in horsepower of spindles and drive motors

- High traverse rates and max cutting feed rates

- Time chip-to-chip tool-change time

- Torque and top RPM

- Coolant through spindle (CTS) systems

· Working Efficiency

Measure productivity indicators of cycle time, feed rate, cutting speed, tool change time, machine load, and takt time to maximize performance, maximize your work development, and also to make sure that the productivity of your CNC milling meets your high production challenges.

· Stability and Rigidity

Stable machines reduce vibration to give smoother cuts and better surface finishes.

High-rigidity frame increases the precision, dimensional accuracy, and extends the life of tools, and is critical to improved repeatable, high-quality machining of a vast array of materials and production needs.

· Tool Storage and Capacity

A higher tool magazine is even more flexible and efficient, as it allows automatic tool exchanges to accomplish different functions in machining.

· Safety Features

Make sure your CNC milling machine is OSHA- and other safety compliance. Consider such features as emergency stops and good safety guards, as well as the compatibility of PPE, to ensure the safety of operators, reduce accidents, and ensure a safe and compliant metalworking atmosphere.

· CNC Controllers

The programmability and the accuracy of the program are influenced by the control system. These are Siemens, Fanuc, Mitsubishi, SMARTBRAIN, and Haas. Select one that best suits the production and operator abilities.

· Automation Support

Complex or high-volume: Select CNC machines with Automatic Tool Changers (ATC), robot loading and unloading, built-in part handling systems, and automation of software to improve productivity, decrease downtimes, and have efficient, constant, and highly accurate machining.

· Ease of Maintenance

Choose machines that will be easily serviceable, to minimize downtime and holding operation costs. Armpro models are constructed to allow ready access and facilities to be reached.

Concerning these checkpoints, you will certainly be in a better position to choose a CNC milling machine on technical, production, and budget reasons.

Conclusion

Selecting a suitable CNC milling machine for your metalworking applications requires a clear understanding of your production requirements, material needs, and tolerances.

Whether it be establishing how many axes are required to make sure the various certifications are maintained, how precise it is, how stable, and how automated it can be, it all matters to your efficiency and the quality of output.

A good machine, where, depending on after-sales count and good warranty, means long-term performance and reliability that you invested in.

Armpro CNC Milling Machines are sophisticated and accurate, but rugged machines that must be up to challenging metalworking. With international approvals, flexible configurations, and highly knowledgeable service, we can support your quest to deliver better outcomes.

Ready to find out how your Armpro CNC Milling Machine can serve you? Go ahead and get in touch today!

Based on the key points just explained to you, I believe you can make a rational choice for a CNC Milling Machines that can meet current production needs and has long-term investment value. Of course, you can also visit the manufacturer's official website (such as https://armpremfg.com/ ) to get the latest customized solutions.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?

Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines: The Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling Milling Machine: The Ultimate Buying Guide in 2024

- CNC Tapping Machine: The Complete Buying Guide in 2024

- Pipe Chafering Machine: The Complete Importing Guide in 2024

- Radial Drilling Machine: The Complete Buying Guide in 2024

- Thread Rolling Machine: The Complete Buying Guide In 2024

- Pillar Drilling Machine: The Ultimate Buying Guide in 2024