BSPP VS BSPT

Introduction

With precision engineering and construction, the selection of the hole design highly determines the efficiency and reliability of the building. Countersinking and counterboring are the two significant methods for shaping holes, but there are some differences in their application and benefits.

These techniques involve different fasteners and materials, and knowing when it is appropriate to use each method can significantly improve the quality and appearance of the finished project.

In any case, the right choice can enhance the final product's functionality and aesthetics in making a tool and heavy machinery or in creating the next eye-catching home decor.

1.What Is BSPP?

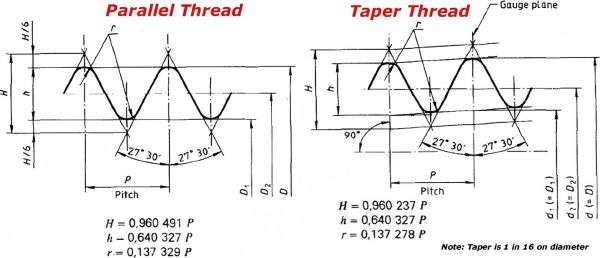

BSPP stands for British Standard Parallel Pipe and is a thread applicable to pipes. The "parallel" in BSPP refers to the thread form being parallel, not tapered.

This type of thread is suitable for fluid applications with low pressure or situations where the thread itself does not hold the pressure.

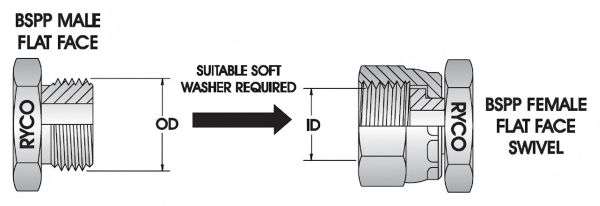

BSPP threads are applied when a gasket or an O-ring is used to ensure the systems do not leak. They can be found in almost every hydraulic, pneumatic, and other equipment requirement where close fitting is required.

The BSPP thread profile is similar to Acme threads used in mechanical systems, like acme lead screws. Acme thread angles and acme screw threads are crucial for understanding how pressure-tight seals work in threaded applications.

2.BSPP Application

You'll typically see BSPP threads used in applications like fluid or gas pipes, fittings, and adapters where a flat seal is required. Typical applications include water pumps, filtration systems, and gas pipelines.

It's also popular in ball lead screw mechanisms, where a leak-free environment is crucial for performance. The acme screw and nut combination in such applications offers both strength and precise motion control.

For example, BSPP threads with additional sealing mechanisms, such as gaskets, are often used to ensure no fluid leaks from a high-pressure system. The acme lead screw sizes come into play here, as they ensure the thread provides both durability and functionality.

In other mechanical systems, like a lead screw mechanism, BSPP threads help seal or join the components securely. Acme thread profiles, like trapezoidal threads, are used in similar systems, offering comparable sealing strength.

3.What is BSPT?

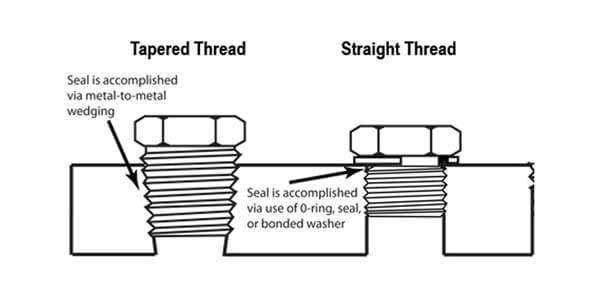

BSPT, or British Standard Tapered Pipe , is another threaded pipe used in various applications, particularly pressure systems. Unlike BSPP threads, BSPT threads have a tapered profile. This means that as you screw the pipes or fittings together, the threads get tighter and form a seal as they are joined.

The design of BSPT threads makes them ideal for high-pressure systems where sealing is done directly through the thread engagement. This self-sealing feature is particularly useful in industries dealing with pressurized gases or fluids, such as oil and gas systems, heavy machinery, and hydraulic applications.

In some cases, BSPT threads might be used for acme screw threads, especially when tight sealing under high pressure is needed, as the taper provides greater force for sealing than parallel threads.

4.BSPT Application

BSPT threads are often used in systems where sealing under pressure is required. This can include machinery, gas pipelines, and certain types of industrial equipment. For example, in trapezoidal screw threads used for lead screws in mechanical systems, BSPT threads may be incorporated to prevent leaks in high-pressure environments.

The trapezoidal thread chart and acme thread calculator can help you determine the correct thread type based on your system's pressure requirements. Acme thread dimensions are chosen based on their ability to withstand pressure, and BSPT is often paired with these for systems that need more robust sealing capabilities.

Because BSPT threads form their seal through the tight engagement of tapered threads, they are commonly used in acme screw thread applications that require self-sealing, especially when combined with acme stub thread connections.

5.How Do You Choose BSPP Or BSPT For Your Application?

To be more precise, you may ask yourself, "What should I do? Which course should I choose between BSPP and BSPT"?" It all depends on the pressure demands, the type of fluid or gas being transported, and the sealing technique needed.

Pressure Sensitivity: If your system experiences significant pressure, the BSPT threads are preferable because they seal themselves. These tapered threads are ideal for use where pressure is likely to cause some leakage. In contrast, essential Pennsylvania Practice (BSPP) might be enough if your system is not under much pressure.

Sealing Method: BSPP threads are self-locking and need an external gasket or `O’-ring to prevent leakage. BSPT requires no additional components to create its seal because it uses tapered threads. If you need a more basic auto-threading method, you should get a system using BSPT threads.

Application Type: BSPP might be a better fit for fluid-based applications where sealing is critical but not under high pressure. BSPT is ideal for industrial and hydraulic systems that deal with higher pressure.

Complementary Threading Systems: When choosing a system, it's essential to consider how BSPP or BSPT may interact with other components, like acme lead screws and trapezoidal lead screw systems. These components often require specific threading types for proper functionality. Consider how the acme screw thread and trapezoidal screw thread profiles align with your needs.

| Feature | BSPP (British Standard Parallel Pipe) | BSPT (British Standard Tapered Pipe) |

| Ease of Installation | Requires additional sealing components | Easier installation with self-sealing properties |

| Compatibility | Often paired with acme lead screws, ball lead screws, and acme screws and nuts. | Often used with acme thread profiles in high-pressure applications |

| Common Thread Sizes | Commonly seen in smaller sizes, fitting industrial and plumbing systems | Used in both large and small sizes, fitting industrial and hydraulic systems |

| Sealing Method | Requires external seals (gaskets or O-rings) | Self-sealing due to tapered threads |

Conclusion

Ultimately, BSPP and BSPT threads serve different needs and should be chosen based on your system's requirements. If you need a self-sealing connection under high pressure, BSPT is your go-to choice.

If you're working with lower-pressure systems and can implement external seals like gaskets or O-rings, BSPP will do the job. Additionally, understanding other mechanical threading systems like acme screw thread and trapezoidal threads will help you design a more efficient, leak-free system.

Whether you're designing a complex system with acme lead screw sizes, integrating ball lead screw mechanisms, or simply sealing pipes, knowing the right thread to choose will save time and money in the long run.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024