How to choose the right tube chamfering machine for specific tasks?

With such a lot of options available on the market, deciding on a tube chamfering device that is well-ideal in your particular necessities can be complex. A tube chamfering device is a metalworking and making tool designed to deliver best results, which means producing perfectly smooth edges at the circumference of tubes or pipes. If you're in manufacturing, construction or another industry wherein steel tubing ought to be processed successfully choosing the right gadget and dealer is prime to receiving a wonderful part.

This article is ready for the distinct machine sorts and discusses how their features work in assisting you find a device that fits your specific wishes. In this guide, you'll apprehend the way to choose the right tube chamfering system when you are finished reading this newsletter.

Introduction

Tube chamfering is the method of doing away with burrs and growing a beveled side at the end of a tube or pipe. This is critical for making sure of a smooth fit while joining tubes, stopping harm, and improving the general aesthetics of the finished product.

The importance of selecting the right pipe chamfering machine.

Choosing the right pipe chamfering system is important for numerous motives, and impacts the efficiency, satisfaction, and universal achievement of a project. Here are the key reasons why choosing the suitable gadget is critical:

- Precision and Quality

An extremely good chamfering machine guarantees unique and steady bevels on the pipe ends. This precision is essential for ensuring that the pipes are in shape collectively perfectly, especially in programs requiring tight tolerances, which include the oil and fuel, car, and aerospace industries.

Increased Productivity

- Cost Efficiency

Investing in a reliable and efficient chamfering system can lead to long-term value financial savings. By minimizing cloth wastage, reducing rework, and lowering hard work prices due to automation, agencies can acquire better financial overall performance.

- Versatility

The proper chamfering machine can take care of diverse pipe sizes, substances, and chamfering angles. This versatility is especially critical for organizations that paint with a huge variety of pipe specifications, as it lets in them to fulfill diverse patron requirements with no need for a couple of machines.

- Consistency

Consistency in chamfering fines is essential for retaining excessive requirements in production.

- Ease of Use and Maintenance

Choosing a person-friendly chamfering system with sincere renovation requirements can reduce downtime and grow operational performance.

1.Understanding Different Types of Pipe Chamfering Machines.

Each sort of chamfering machine is designed to meet precise needs, from small-scale operations to large business packages. Understanding the different sorts lets you pick out the right gadget for your unique needs.

- Overview of various types of pipe chamfering machines and the specific tasks each type is best suited for.

Following are numerous types of pipe chamfering machines:

- Manual Pipe Chamfering Machines Handheld Chamfering Tools:

Portable gadgets are used to create a chamfer on small to medium-sized pipes. It is Suitable for on-website online work or small-scale operations.

Best Suited For:

Small to medium-sized pipes; short and on-site chamfering obligations.

Bench-Mounted Chamfering Machines:

It is fixed to a bench or table, these machines offer stability for chamfering responsibilities.

Best Suited For:

It is suitable for Medium-sized operations that require greater balance than handheld gear can provide.

- Automatic Pipe Chamfering Machines

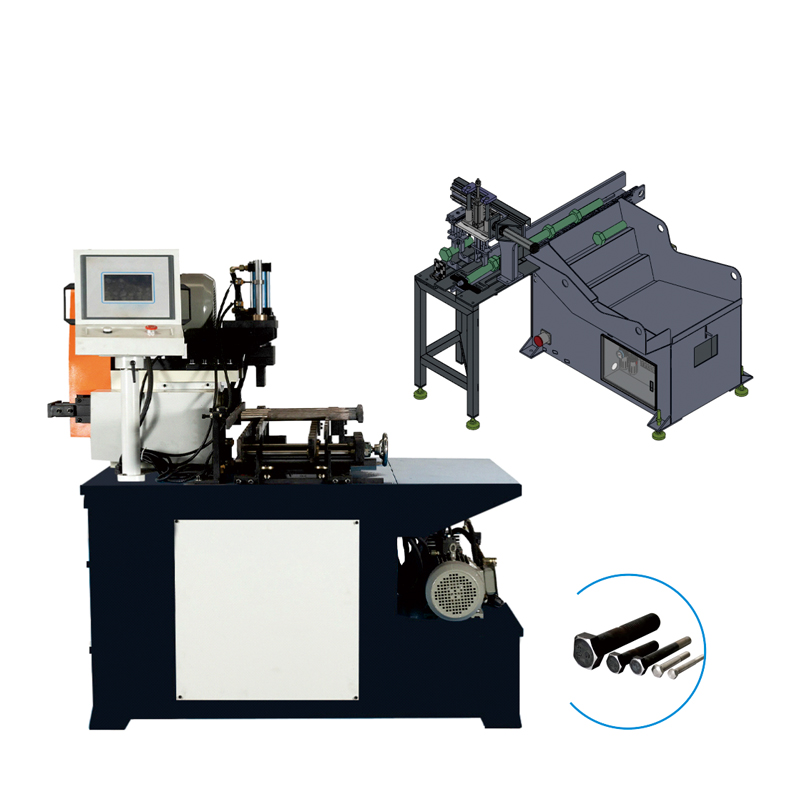

Single-End Chamfering Machines:

In this type Chamfers one end of a pipe at a time.

Best Suited For:

- High-quantity operations where pipes need to be chamfered on one end fast and correctly.

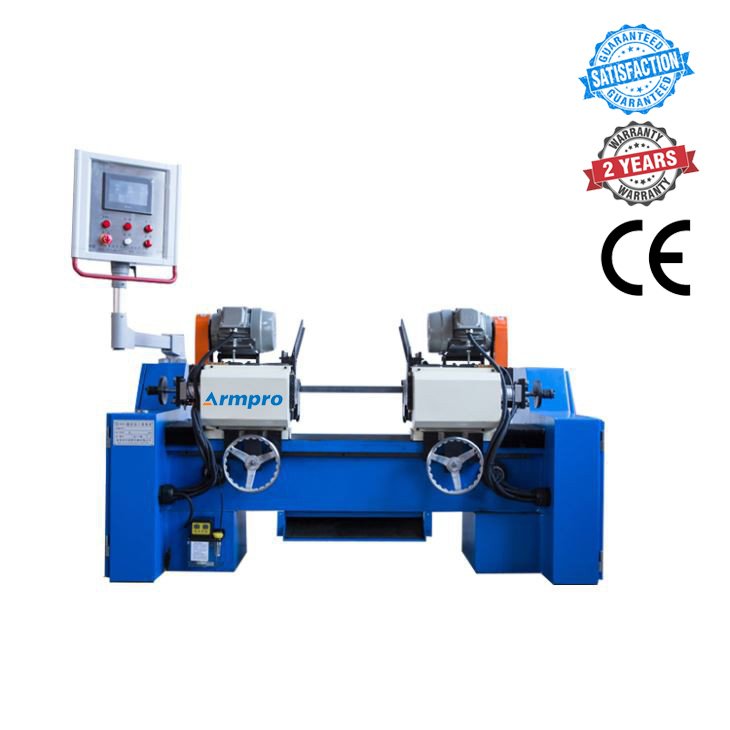

Double-End Chamfering Machines:

Can chamfer each end of a pipe concurrently.

Best Suited For:

- High-quantity production wherein both ends of pipes want chamfering concurrently.

- CNC Pipe Chamfering Machines

CNC Chamfering Machines:

It is a: Programmable machine supplying excessive precision for complex chamfering responsibilities.

Best Suited For:

Large-scale manufacturing requiring excessive precision and programmable operations

CNC Lathe Machines with Chamfering Attachments:

Standard CNC lathes equipped with chamfering attachments.

Best Suited For:

Versatile operations combining turning and chamfering capabilities.

2.Factors to Consider When Choosing a Pipe Chamfering Machine.

By taking these factors into account, you could choose a pipe chamfering device that meets your specific necessities, enhances productiveness, guarantees safety, and affords terrific effects.

- Understanding the Task Requirements

- Material

It Ensures the machine can cope with the kind of fabric you will be running with, including steel, stainless steel, aluminum, copper, or plastic. Additionally, consider if the device is designed to work with the hardness or brittleness of the fabric.

- Size

Diameter Range: Verify that the device can accommodate the variety of pipe diameters you need to chamfer.

Wall Thickness: Check if the machine can cope with the pipe’s wall thickness.

- Precision

- Chamfer Specifications: Determine the required chamfer attitude, period, and finish.

- Tolerance: Ensure the machine can gain the essential precision and consistency in your

- Evaluating the Machine's Capabilities

Speed

- Production Rate: Assess the device's chamfering velocity and its ability to fulfill your manufacturing extent wishes.

- Cycle Time: Consider how quickly the gadget can entire every chamfering cycle.

Accuracy

- Consistency: Look for machines that provide constant and repeatable outcomes.

- Adjustability: Ensure the system allows for high-quality changes to meet unique specs.

Automation

- Level of Automation: Decide in case you need a totally automated system, a semi-automated system, or a guide one based totally to your production wishes and finances.

- Integration: Consider how nicely the device can integrate with your current workflow and other systems.

- Considering the Machine's Safety Features and Ease of Use.

Safety Features.

- Emergency Stops: Ensure the machine has without difficulty handy emergency stop buttons.

- Safety Guards: Check for protecting guards and covers to save you injuries.

- Compliance: Verify that the machine complies with applicable protection requirements and policies.

Ease of Use

- User Interface: Look for an intuitive control panel and consumer-friendly interface.

- Training Requirements: Consider the quantity of training required for operators to use the gadget efficiently.

- Maintenance: Evaluate how smooth it is to hold and clean the machine, which includes getting the right of entry to replaceable elements and technical support.

3.The Role of Pipe Chamfering in Different Industries.

- Examples of Industries Where Pipe Chamfering Is Essential.

- Oil and Gas Industry

- Pipeline Construction: Chamfered pipes ensure smooth joints and reduce the danger of leaks, that is critical for transporting oil and fuel

- Drilling Operations: Chamfering is essential to put together drill pipes and casings, making sure they join securely and might withstand excessive stress.

- Plumbing and Water Supply

- Pipe Fittings: Chamfered ends permit for higher connections and decrease the hazard of leaks in plumbing structures.

- Water Mains: Chamfering helps within the smooth meeting of big-diameter water mains, making sure a reliable water deliver network.

- Automotive

- Exhaust Systems: Chamfering is used to prepare exhaust pipes for welding and assembly, making sure a good and stable suit.

- Hydraulic Lines: Chamfered edges are crucial for the right becoming of hydraulic pipes, which might be crucial for vehicle braking and guidance systems.

- Aerospace Industry

- Fuel and Hydraulic Systems: Chamfered pipes are important for the steady fitting of gasoline and hydraulic lines, which must withstand high pressure and temperature variations.

- Structural Components: Precision chamfering ensures that structural pipes fit appropriately and securely, retaining the integrity of the aircraft.

- Manufacturing Industry

- Production Lines: Chamfered pipes are frequently required in production lines for clean operation and meeting of diverse additives.

- Machinery: Chamfering is important for preparing pipes that are a part of complicated machinery, ensuring unique fits and decreasing put on and tear.

- Specific Tasks in These Industries That Require Pipe Chamfering Machines

Oil and Gas.

- Pipeline Installation: Chamfering system prepares pipe ends for welding or threading.

- Maintenance and Repair: Chamfering broken or worn pipe ends earlier than reinstallation.

Plumbing and Water Supply.

- Pipe Joining: Chamfering gadget prepares pipes for steady joint connections using numerous methods, which includes welding or adhesive bonding.

- Fitting Preparation: Chamfering guarantees pipes fit correctly with couplings, elbows, and other fittings.

Automotive

- Welding Preparation: Chamfering exhaust and different pipes earlier than welding to ensure a smooth, strong weld.

- Component Assembly: Preparing hydraulic and gasoline lines for steady, leak-unfastened connections.

Aerospace

- Precision Fitting: Chamfering pipes for accurate becoming in gasoline, hydraulic, and structural systems.

- Component Fabrication: Chamfering as part of the producing manner for excessive-precision aerospace additives.

Manufacturing

- Machine Assembly: Chamfering pipes for precise meeting in diverse types of machinery.

- Production Line Maintenance: Preparing alternative pipes for seamless integration into manufacturing structures.

4. Case Study: Choosing the Right Pipe Chamfering Machine.

Choosing the right pipe chamfering device is critical for ensuring outstanding pipe processing, extended efficiency, and decreased operational charges. This case study explores the selection-making method of a mid-sized production enterprise, "Precision Pipes Ltd.," as they navigate the complexities of selecting the right chamfering gadget for their operations.

- Practical example:

Imagine a manufacturing organization that produces steel pipes for various industries. These pipes need to have unique chamfering (beveling) on the ends to ensure proper suit and safety when they're joined together.

Instead of manually chamfering each pipe, which is time-eating and inconsistent, the corporation decided to spend money on a pipe chamfering system.

By the use of the pipe chamfering machine:

- The company improves the performance of its manufacturing method.

- They ensure uniformity and precision inside the chamfering of every pipe.

- Labor costs are decreased because fewer people are wished for this repetitive project.

- How the chosen machine has improved efficiency and product quality.

Improvements in gadget efficiency and product first-rate can be attributed to several elements depending on the enterprise and specific technology concerned.

- Automation: Machines can perform repetitive responsibilities with regular precision and speed, reducing human mistakes and variability in production approaches. This leads to better performance and more uniform product excellence.

- Precision and Accuracy: Advanced equipment regularly consists of unique dimensions and control structures, ensuring that products are manufactured to actual specifications

- Speed of Production: Modern machines can perform a whole lot faster than human employees in many responsibilities, growing usual manufacturing costs and throughput without sacrificing fines.

- Reduction of Waste: Efficient machines can optimize raw material usage and limit waste technology at some point in manufacturing processes, mainly to price financial savings and environmental benefits.

- Quality Control: Many machines are ready with sensors and tracking systems that could hit upon defects or inconsistencies in actual time. This allows for fast changes and ensures that handiest outstanding products are delivered to clients.

- Flexibility and Adaptability:Some machines are designed to be versatile and effortlessly reconfigurable for specific manufacturing wishes.

Conclusion

In the end, careful attention while selecting a pipe chamfering device isn't always just about selecting a system; it's about making an investment that complements productivity, ensures product excellence, and helps lengthy-time period enterprise achievement.

By comparing technical specs, assessing operational wishes, and prioritizing support and reliability, producers could make knowledgeable selections that yield effective consequences throughout their operations.

"Pipe chamfering" plays a pivotal role in several industries, including production, car, plumbing, and production. It entails beveling or chamfering the rims of pipes to facilitate assembly, welding, or sealing.

This process enhances joint integrity, reduces strain concentrations, and improves overall structural stability in assemblies.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024