JIC vs AN: Understanding the Differences and Choosing the Right Fitting

Introduction

Hydraulics and fluid systems have to offer quite a lot of machining design capabilities for fitting applications JIC vs AN. Even with these applications for their consideration, both fittings maintain a high level of respect in terms of reliability and performance, which is where they draw their ends apart in their respective design history.

This blog takes a look at the JIC versus AN argument, tackling issues such as what each fitting is and where it is used, then ultimately putting forth an easy way for you to choose which one meets your needs.

This guide will explain NPT vs NPTF threads in detail, which kind is suitable for use, and how to establish that you are using the right thread.

1. What Is JIC?

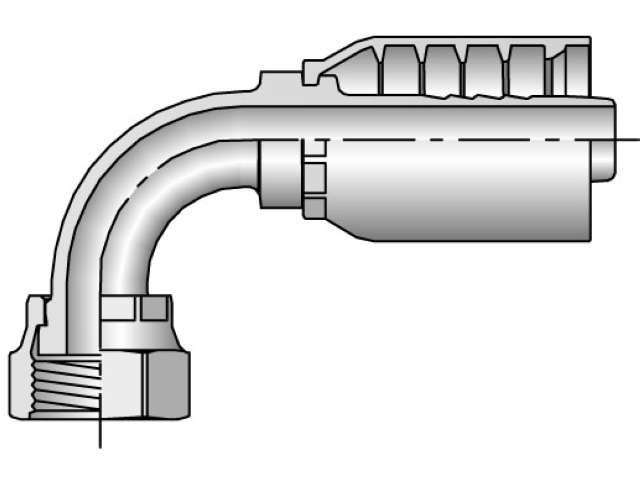

The abbreviation of JIC derives from its original name-Joint Industry Council. JIC fittings are flare-type fittings characterized by a 37-degree flare seat angle with the objective of providing a secure, leak-free interface between tubing and hose.

The creation of the mid-20th century was developed by a partnership among industrial leaders in order to standardize hydraulic fittings for more general commercial use. So, what is JIC? A general-use, precision-engineered fitting that has become a staple for industries requiring robust fluid-transfer systems.

Design parameters for JIC fittings also provide dash sizing (e.g., -4, -6, -10), where the number denotes the tube's outer diameter in 1/16-inch increments. As such, a -8 JIC will fit a 1/2-inch tube, together with a given thread size, such as 3/4-16.

This standardization, compliant with the requirements of SAE (Society of Automotive Engineers), ensures compatibility from manufacturer to manufacturer and represents practicality when choosing JIC fittings from an engineer's or technician's standpoint across various projects.

2. JIC Application

The application range of JIC fittings is extensive, thanks to their durability and adaptability. What does JIC mean in practical application? The fitting solution is trusted throughout automotive, industrial, and agricultural applications.

Automotive high-performance fuel lines, oil cooler, and hydraulic systems for brakes or steering services, pressure and vibration with JIC fittings. JIC fittings connect hydraulic lines responsible for significant functions used on heavy equipment such as excavators, tractors, and industrial presses.

JIC fitting applications include production plants connecting pumps to valves in fluid transfer systems. Being able to maintain tight seals under changing conditions means that dynamic and static applications are covered.

JIC fittings are widely used for reasons that answer the question of cost, ease of availability, and performance, making them the standard option for people needing reliable connections in slightly demanding settings.

3. What Is AN?

To define AN, it stands for Army-Navy, which hints at the fact that these fittings were developed with respect to their military applications during World War II for aerospace use.

AN is a flared fitting, using a 37-degree angle like the JIC, but designed to much higher military standards for precision and reliability. What, then, is AN, it is a fitting built for extreme conditions where it will never fail.

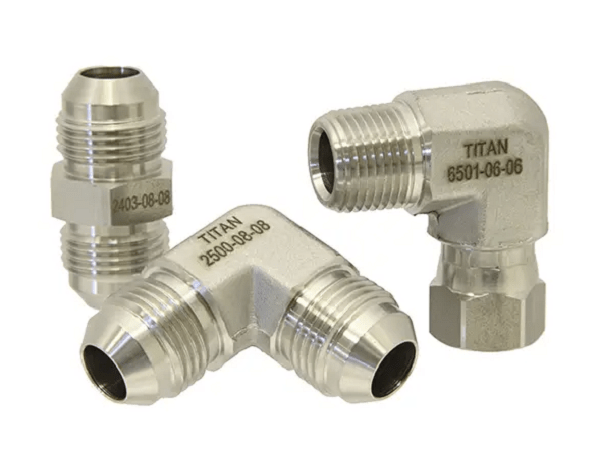

While sharing the exact dash sizing of AN with that of JIC-e.g., -6 AN equals a 3/8-inch tube with a 9/16-18 thread-AN fits more stringent tolerances and higher quality specifications such as those listed in MIL-SPEC (Military Specification).

Most AN fittings were initially developed for aircraft fuel, hydraulic, and oil systems attached to very lightweight and high-strength materials. This is because they had an aviation heritage, which makes them stand above other fittings in the marketplace.

4. How To Decide Between JIC And AN For Your Application?

The consideration between JIC vs AN may be determined by several factors associated with your particular application. Although they share a standard 37-degree flare and the same dash size convention, their variations in design intent, quality of construction, and cost may serve as the choice between them.

AN fittings, however, would be leading in critical performance applications. They are mil-spec tolerances, and better finishes make them good for aerospace, motorsports, and other high-pressure, high-vibration environments.

If you are plumbing an airplane's hydraulic lines or a race car nitrous system, AN precision gives the highest level of safety and durability. But that also costs a premium- fittings are usually more expensive and may require some specific tools or components, such as AN-specific hoses.

However, JIC fittings present a practical option for a less critical condition. Because of their industrial origins, JIC fittings are readily available and, hence, affordable; therefore, they become effective on the majority of automotive repair jobs, maintenance of heavy equipment, and hydraulic setups.

However, JIC fittings fail to possess those high tolerances of AN, which may be critical in ultra-critical systems, although they can withstand considerable pressure, often up to 5,000 PSI, depending on size and material. Compatibility is another incentive, as JIC fittings are likely to mate with more standard hoses and adapters.

The recommendation of using different materials has also become an issue when choosing JIC vs AN. AN fittings are usually manufactured with lightweight aluminum or stainless steel and anodized to resist corrosion and are aesthetically pleasing for applications that are visible, such as car engine bays.

JIC fittings should be steel, brass, or aluminum, as they will be used for very rugged, utilitarian needs. The surrounding environment to saltwater or extremes of temperature should determine whether you will be using the stainless steel AN or settling for a less-expensive option like the JIC.

Pressure ratings and regulatory requirements round out the considerations. AN fittings, built to MIL-SPEC, meet stringent aerospace and military standards, while JIC aligns with SAE norms suitable for commercial use. If your project demands certification or operates under intense scrutiny, AN might be non-negotiable. For everyday builds or repairs, JIC often suffices without breaking the bank.

Conclusion

The JIC vs AN comparison reveals two fittings with shared DNA but divergent paths. The JIC meaning—Joint Industry Council—points to a standardized, accessible solution for industrial and automotive fluid systems. JIC uncovers a fitting that balances cost and capability, as seen in its broad applications from tractors to factory floors.

Meanwhile, AN highlights a premium fitting crafted for precision in aerospace and high-performance contexts.

Ultimately, understanding these fittings empowers you to match them to your project's requirements. Whether you're maintaining equipment or pushing the limits of performance, the decision shapes the reliability and efficiency of your fluid system.

JIC and AN each bring strengths to the table, ensuring there's a fitting for every challenge in the intricate world of hydraulics and beyond.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024