Male Fitting vs Female Fitting: Meaning, Uses, and Key Differences

Introduction

You've probably heard of male fittings and female fittings if you've ever had a chance to work on plumbing connection, gas connector , or industrial piping. These two types of connectors are popularly found everywhere, from houses to factories to farmlands and even cars. But many people still mix them up or don’t fully understand how they work.

So what’s the deal with male fitting vs female fitting? Why do both exist, and how do you know which one to choose?

Let’s break it all down — from female plumbing fittings, male plumbing fittings, to the difference between male and female fitting, including how they’re used, and when to pick one over the other.

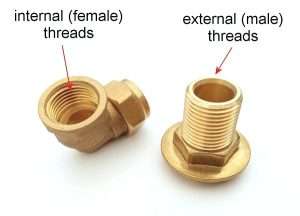

1. What Is Male Fitting?

Let’s start with the basics. The male fittings are one of the fittings, one part that has male threads or extensions that stick out. Its job is to fit into something else, which is usually a female fitting.

In short, a male fitting or male connection inserts into another piece to create a secure plumbing connection.

This type of fitting is used in many different systems. While talking of the male threads, the reference is usually to historical designs that use external thread or push-fit fittings for connecting pipes or hoses. Male fittings or male connections are the traits common in plumbing works, gas lines, hydraulic systems, and specific HVAC apparatus.

The male fitting system includes different types, such as:

-

- Threaded male fittings with external threads

- Push-connect male fittings that slide into place without threads

- male to female gas connector

- male to male fitting, male to female fitting

The reason people rely on the male hose connector is that it’s quick to install, holds tight, and works with various materials like brass, copper, and plastic.

2. Male Fitting Application

Now let’s look at how male fittings are actually used.

So, who uses the male fitting? The short answer: almost everyone in mechanical, fluid, or gas-related work. From homeowners fixing a sink to engineers managing pipelines.

Male fittings show up in all sorts of male connection applications. Here’s where they’re commonly used:

- Plumbing systems for pipe and valve male connector

- Hydraulic tools and machines in factories

- Gas lines for cooking, heating, or industrial work

- Air conditioning and heating systems

- Garden and irrigation setups

- Vehicle parts like brake lines and gas connector

- Male female ball valve,

The male fittings is popular in these setups because it’s strong, reliable, and handles pressure well. Once you screw in or push a male fitting into place, it creates a tight seal that holds up — even under heavy use.

3. What Is Female Fitting?

Now let’s move to the other half of the thread connection — the female fitting.

So what is it? A female fitting is designed to receive a male fitting. It has female thread also

called internal threads or an opening that allows the male part to fit inside. Together, they create a sealed connection.

If a male fitting sticks out, the female fitting stays open. It’s like a socket for the male end to lock into.

Female fittings can also be threaded or push-connect. They are just as important as male fittings and will almost always be found on the receiving end of any pipe, tube, or hose connection, gas connector

These fittings have everything engineered to withstand pressure, prevent leakage, and allow smooth running of operations.

4. Female Fitting Application

Female fittings are used in just as many places as male ones. They're found in homes, on industrial plants, medical apparatus, and outdoor systems.

Female fittings come into play when installing plumbing on faucets, sinks, or toilets. They are also employed in the large-scale pipelines used for chemical transportation and even hospital gas lines.

Wherever a male fitting goes in, a female fitting is there to hold it.

Here’s a quick look at some common uses for female fittings:

plumbing connection in homes and buildings

Fuel and gas systems in commercial spaces

Industrial piping for chemicals and fluid

Medical equipment for oxygen or, gas female connector

Farm irrigation systems

female to female fitting, female to male fitting

The female fitting plays a crucial role. Without it, the system can’t seal or hold pressure. And just like male parts, female fittings must be the right size and type for the system to work.

5. How to Choose Male Fitting or Female Fitting for Your Application?

So here’s the big question — how do you know which fittings to use?

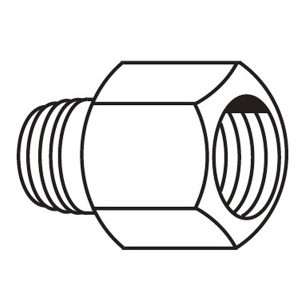

Let us take a closer look at male fitting vs female fitting,or male threads vs female threads. Examining how to select the right fittings for your system,and how to choose the male female joint.

| Feature | Male Fitting | Female Fitting |

| Thread Type | Male threads(External threads) or

push in fitting |

Female threads(Internal threads) |

| Connection Roll | Starts the connection | Locks and seals the system |

| Installation Position | Goes into the female threads | Receives the male fitting |

Now that you know the core difference, it’s time to choose the right one. Here’s how:

Check Your Existing System First

Before anything else, take a look at what you already have. If the part you’re working with has external threads , that’s a male fitting. In that case, you’ll need a female fitting to match. On the other hand, if it's internal threads, the fitting is a female fitting and will require a male fitting for connection.

Think About Available Space

Space matters more than most people think. If your workspace is tight or crowded, a female fitting might be the smarter option. It won’t stick out as much, making installation a little easier. Male fittings take up more room, so in compact setups, they might be harder to fit in.

Consider System Pressure and Movement

This isn’t just about which one is stronger. male female plumbing fittings choices depend on how well the parts match and hold together under pressure or movement. Both can handle tough conditions, as long as they’re paired correctly. A weak match-up is where leaks and failures happen.

Match Materials Correctly

Not all materials go together. If you’re using plastic fittings, some metals might wear them out or cause leaks. The male fitting and female fitting need to be compatible not just in size but also in material. This detail can make or break your setup.

Think About Maintenance and Reuse

Threaded male and female fittings are the best choice of fittings if you ever want to separate them. It saves time because it is simple to connect or disconnect. This makes repairs or upgrades simple. But if you use push connect, they may not come apart as easily once installed, such as male female joint.

Choosing between the two comes down to fit, male threads vs female threads,function, and the kind of system you're working on. There’s no universal rule. Male threads vs female threads ? Sometimes you’ll need a male fitting, sometimes a female fitting, and often times both.

Conclusion

Now you know the full story behind male fitting vs female fitting.

The male fittingis simple: it connects by sliding or threading into another part. It’s used across homes, factories, and farms — basically anywhere that fluid or gas moves. The male fitting is trusted because it seals tightly, installs quickly, and handles pressure very well.

You also learned who uses the male fitting — and it turns out, just about everyone who works with pipes, hoses, or tubes. From irrigation to automotive systems, male fittings play a central role.

Then there’s the female fitting — the part that receives and locks the male fitting in place. It completes the connection and holds everything together.

When choosing between them, understanding the difference between male thread and female thread is key. Match the parts properly, and your system will run smoothly.

Still confused about which fitting to choose? Just remember this: The male fitting goes in, and the female fitting receives it. Get the pairing right, and you’ve already solved half the problem.

Related Reading

1. What is AN Fitting?

AN Fitting, also known as Army Army-Navy joint, is a specialized component primarily used in high-performance fluid systems to help achieve safer leak-proof connections between pipelines.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024