Features

Armpro AT16 automatic tapping machine enables tapping operation automatically.

The automatic mode can effectively control the depth of tapping, automatic control by depth.

The integrated input field can be used to switch between automatic and manual mode, jsut simply set thread depth and speed.

The low maintenance and operating costs as well as the pleasant working volume are also an advantage favored by users.

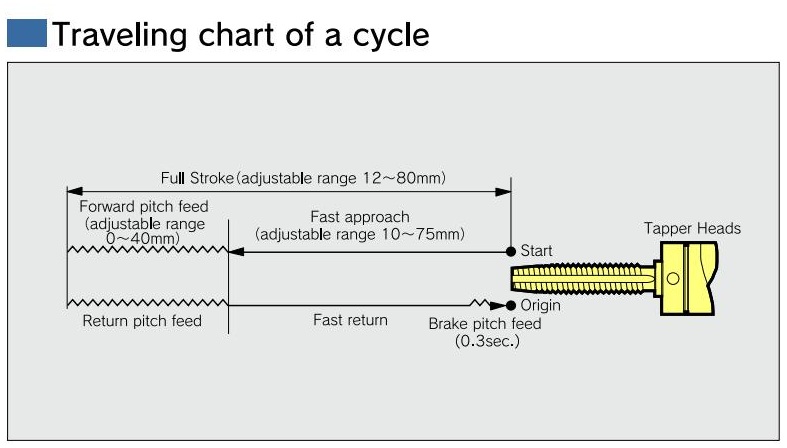

Tapping cycle time can be greatly reduced using Fast approach and Fast return mechanisms.

The built-in Fast approach and Pitch Feed automatic switch mechanisms significantly cut down idling time during the tapping process.

Tapping machine with a 100mm Long Full Stoke. Capable of avoiding interference with fixtures or peripheral devices and making it easiler for tool change.

Capable of mounting multi-spindle tapper head on tapping machine to reduce greatly on tapping cost

Specification

| AT12 | AT16 | |

| Max. Tapping capacity | M2-M12 | M2-M14 |

| Spindle Travel | 100mm | 100mm |

| Spindle taper | JT6 | JT6 |

| Motor Power | 1200W | 1200W |

| Max Spindle speed | 833rpm | 555rpm |

| Column Dia | 74mm | 74mm |

| Distance between spindle end to table | 400mm | 400mm |

| Distance between Spindle axis to column generating line | 270mm | 270mm |

| Spindle taper | JT6 | JT6 |

| Tap collet | M2-M12 | M2-M14 |

| Screw Pitch range | 0.4mm, 0.45mm, 0.5mm, 0.7mm, 0.8mm, 1mm, 1.25mm, 1.5mm, 1.75mm

40teeth/inch, 36teeth/inch, 28teeth/inch, 26teeth/inch, 24teeth/inch, 22teeth/inch, 18teeth/inch |

|

| Base dimention | 300*350 | 300*350 |

| N.W | 100kg | |

| Overall Size | 550*550*800 | 550*550*800 |

| Voltage: | 220/50hz (If require other voltage, pls specific) |

The selection of cutting speed rotation speeds should be based on the material type of the work, cutting characteristics, diameter and material of taps, cutting speed, etc.

Select the most appropriate feed gear for the tapping pitch to be used.

Reviews

There are no reviews yet.