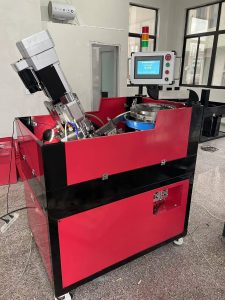

- The automatic tapping machine will not have broken wires and missing tapping. It is not easy to damage the wiretap. If there is any doubt, the equipment will actively alarm and stop.

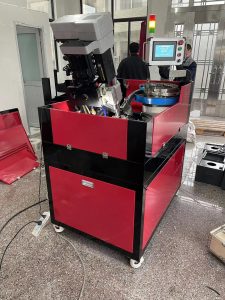

- The automatic tapping machine is customized according to the customer’s sample plan, with good stability, high power, high precision, fast speed, low investment, and a short cost recovery period.

- The automatic tapping machine works stably, maintenance and repair are more convenient, the failure rate is extremely low, and the power consumption of the equipment is low. This equipment can be shared by a variety of similar products.

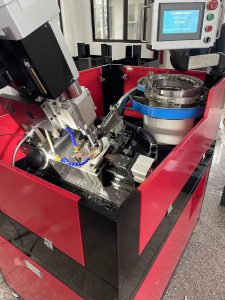

- It is easy to replace the workpiece with an automatic tapping machine. It only needs to change the disc mold and the clamping material. Because the main machine is inclined, the tapping chips are easily cleaned, and the cutting oil can deepen the workpiece and achieve the best smoothness.

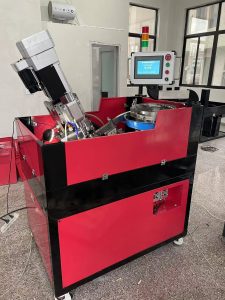

- Hardware processing products, precision parts for cars, electronics, special-shaped nuts, rivets, rivet nuts, etc.

- This equipment is mainly aimed at threading pins, rivet nuts, connecting shafts, short shaft parts, sleeves, valve cores, grinding head rods, small pipe fittings, and various non-standard hardware car parts inner hole tapping processing, blind holes can be processed The fixture can be flexibly replaced with through-hole products and can be used for tapping processing of workpieces with different shapes.

Reviews

There are no reviews yet.