Countersink VS Counterbore: Applications, Differences, And Choosing The Right Fit

Introduction

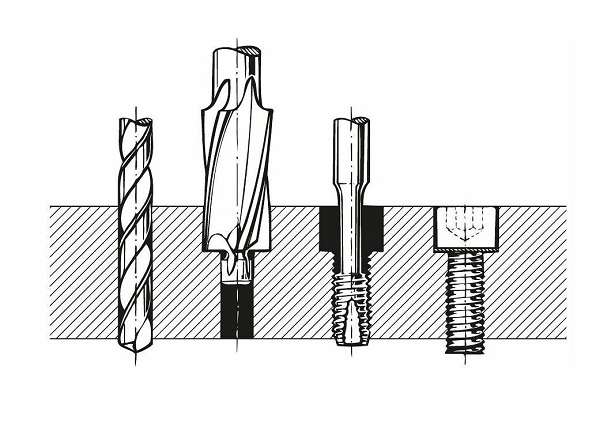

Ever wondered why some screws sit perfectly flush with the surface while others are recessed into the material? This precision isn’t magic—it’s the work of either countersinking or counterboring.

These techniques ensure fasteners don’t just hold things together but also do so with style and purpose. Whether you’re assembling a complex machine with an Acme lead screw, designing a system using trapezoidal lead screws, or simply ensuring your fasteners don’t interfere with moving parts, understanding these methods is vital.

Both countersink and counterbore offer specific benefits depending on the type of fastener and application. The choice often boils down to the kind of project you’re working on and the mechanics at play.

For instance, systems using acme threads and trapezoidal threads usually rely on these techniques for precision alignment and performance. Let’s break down these two techniques, their uses, and how to decide which fits your needs.

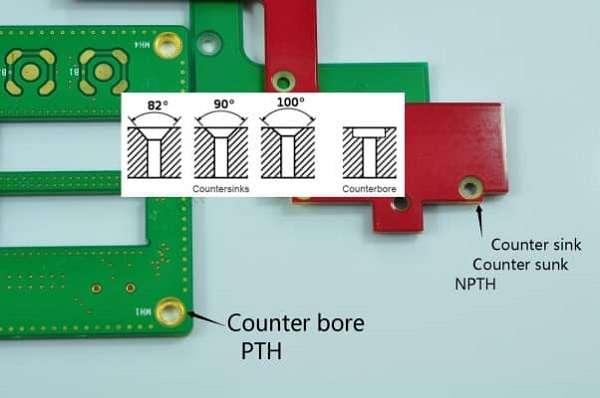

1、What Is Countersink?

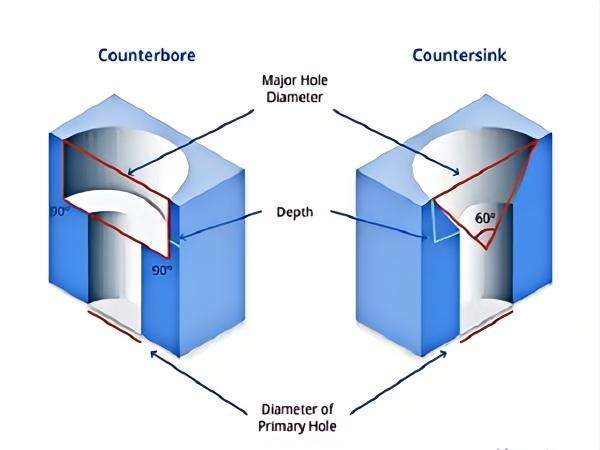

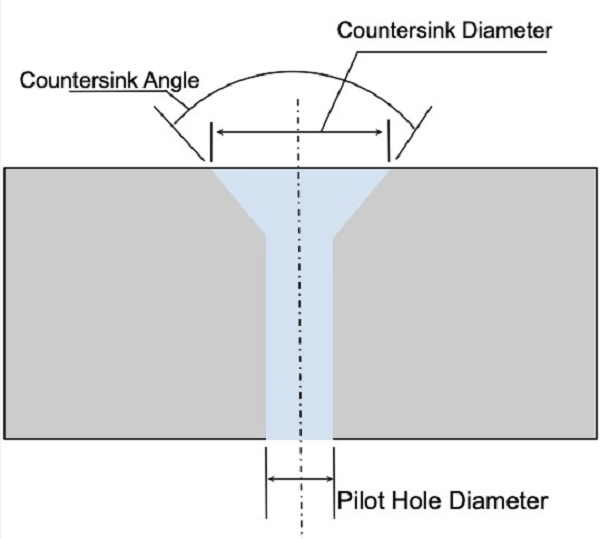

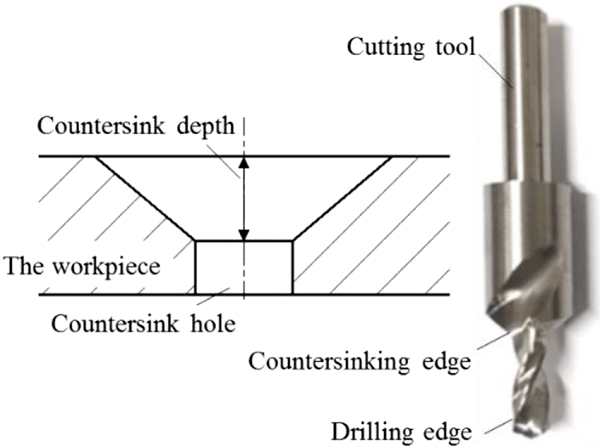

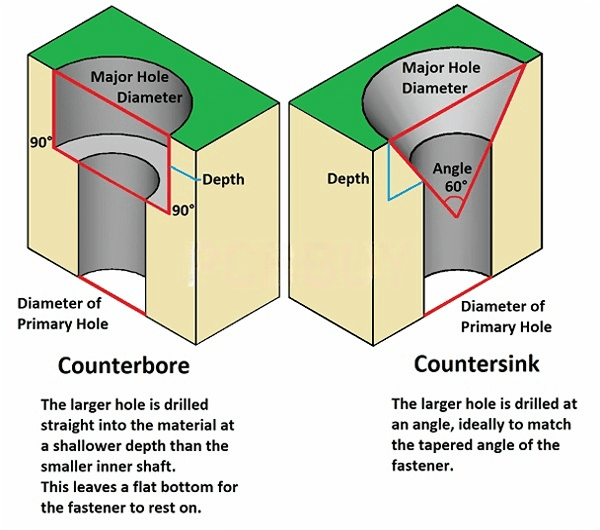

A countersink defined as a conical hole that provides a flathead screw or bolt at a level with or below the material surface. This is done employing a countersink bit that carves a taper around the hole through which the screws shall be inserted in.

Key Features of a Countersink are:

- The hole tapers outward, resembling a funnel.

- It is designed specifically for screws or fasteners with a flat or tapered head.

- Provides a neat, polished finish without protruding screws.

In projects involving components like Acme screws and nuts, countersinking ensures the screw head doesn’t interfere with moving parts, especially in applications with follower nuts or lead screw mechanisms.

2、Countersink Application

Countersinking is widely used in:

Woodworking: This creates smooth, flush finishes on furniture and cabinetry.

Metalworking: Often seen in machinery and tools using acme thread rods or trapezoidal screw threads, where precision is critical.

Aerospace: To maintain aerodynamic surfaces free of protruding screws.

Plastics: Ensures screws do not crack or stress the material over time.

A well-countersunk hole is essential when working with precision systems, such as an acme lead screw mechanism, where even the slightest interference can disrupt smooth operations.

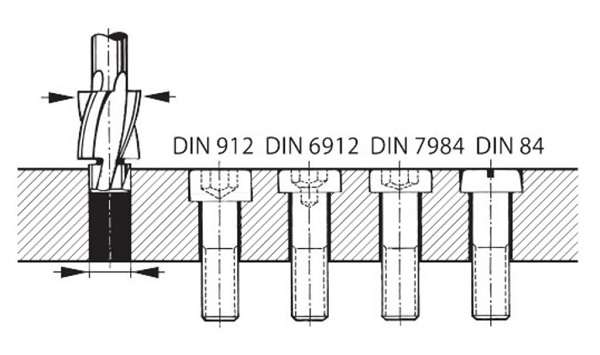

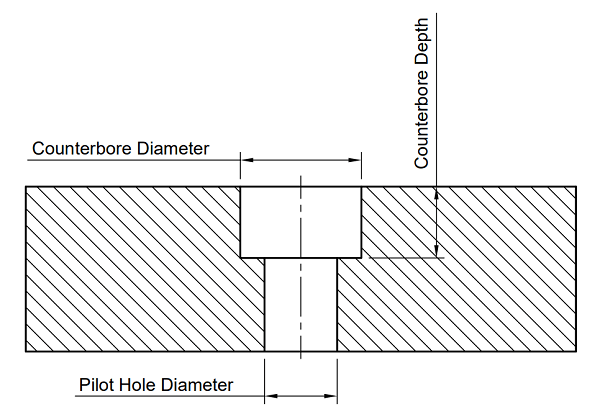

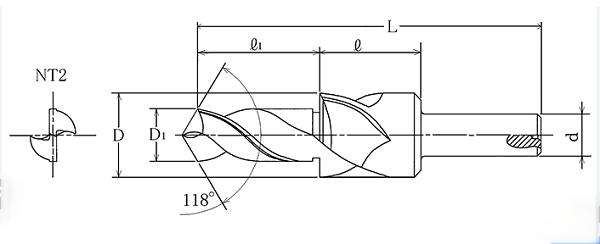

3、What Is Counterbore?

Compared to this, a counterbore is a cylindrical hole through which a bolt head can lay flat or partially sunk into the material in question. While you will use countersink to produce a tapered hole, counterbore will give you a flat-bottomed hole great for screws or bolts bearing a cylindrical head.

Key Features of a Counterbore are:

- Creates a circular hole on the workpiece with a horizontal floor.

- Used for fasteners having round or Hexagonal heads.

- Permits the use of washers beneath the bolt heads.

In machinery relying on acme threads and trapezoidal threads, counterbores prevent fasteners from interfering with sliding or rotating parts, such as in acme thread rods or stub acme threads.

4、Counterbore Application

Counterboring is commonly used in:

Heavy Machinery: Perfect for applications using ball lead screws or acme lead screws, where stability and alignment are critical.

Structural Applications: Ideal for bolted joints in bridges and heavy frames.

Precision Engineering: In systems using acme screw threads or trapezoidal thread charts, counterboring ensures consistent alignment of components.

Counterbores are particularly important when working with metric trapezoidal screw threads or stub acme threads, ensuring bolts don’t compromise the integrity of the mechanism.

5、How To Choose Countersink Or Counterbore For Your Application?

Counter sinking or counter boring is determined by the kind of fastener used and the project requirements during construction. Here’s a breakdown to help you decide:

1. Type Of Fastener

For flathead screws and bolts, you should use a countersink since it creates recesses necessary for a flat/oval head to lay flat. The counterbore should be selected if the fastener head is cylindrical or hexagonal, like a bolt with washers.

Countersinking is applied to the flat head screws, especially for acme screw threads or trapezoidal screw threads. Still, counterboring is used with bolts, and washers cover the head to ensure secure tightening.

2. Aesthetic Requirements

Countersinking is perfect for giving the workpiece a smooth, flush finish. It is suitable for any project where appearance is desirable, including furniture or cabinetry.

However, counterboring is more effective for industrial or heavy-duty utility as it creates space for washers and holds the fasteners in place. Counterboring can be used when you are dealing with acme thread profiles or having a 29° thread angle; this will help eliminate any protruding fasteners.

3. Load And Stress

Counterboring relieves stress in a better way and is, therefore, helpful in high-load applications such as ball lead screws or acme lead screw sizes. It checks whether the material and the fasteners can withstand the pressure exerted.

Counter sinking is just enough for less stressful applications where little stress is placed on the joint, and the main objective is to have a flush surface.

Conclusion

Regarding precision engineering and building robust systems, the choice between countersink and counterbore plays a crucial role. These methods are not just about creating holes—they’re about ensuring stability, longevity, and a flawless finish. Countersinking is the perfect match when aesthetics and flush finishes are a priority, making it ideal for projects that rely on flathead fasteners. On the other hand, counterboring is the go-to solution for heavy-duty applications where strength and alignment are paramount, especially when working with components like acme lead screws, trapezoidal screw threads, or stub acme threads.

Thus, knowing the difference between the two, you do not have to stress yourself while implementing your designs since each one is designed to do a specific thing.

Accuracy, utility, and speed – these principles explain a successful project, and they begin with the proper equipment and methods.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024