AN Fitting Size Chart: Everything You Need to Know

Introduction

You may have heard of the fitting called the AN fitting if your hands have ever been dirty with cars, planes, or anything that moves fluids. These little connectors are the unsung heroes of high-performance systems, and if you know how to use them, you will save yourself a headache or two.

So, what exactly is an AN fitting? This article will cover what an AN fitting really is, how the sizes work, what its materials are, and what its applications are. You will be all equipped with confidence on your next project.

1. What is AN Fitting?

The AN fittings were initially introduced during World War II and primarily served to connect hoses and fluids with different appliances in an aerospace environment.

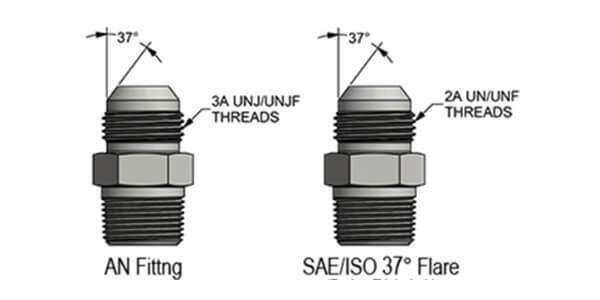

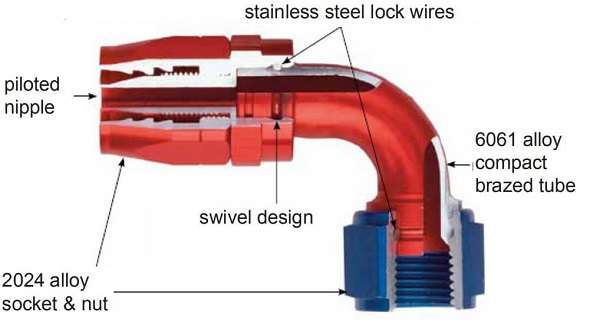

Any description that sums them up is trustworthy; they tightly seal using a 37-degree flare that offers leak-proof assurance between hoses and metal tubing, and that is the reliability of a system one bets on w.r.t precision and performance; automotive racing, aviation, and even marine setups are all excellent examples.

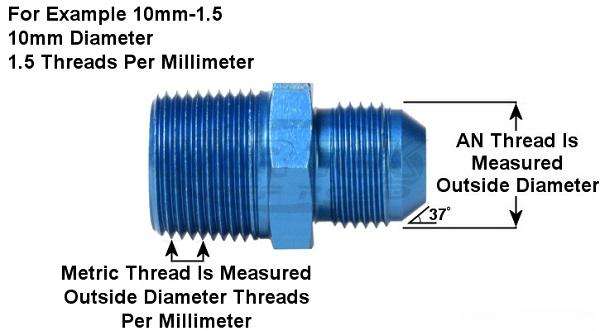

To measure an AN fitting is as tricky as a street crossing without crossing; since there are various sizes labeled with dash numbers, examples being -4, -6, and, 10-the sizes correspond to an outside diameter of tubing. It should fit, measured in 1/16ths of an inch, so the -4 AN fitting goes to a tube having an OD of 4/16 or 1/4 inches, -6 therefore means 6/16s or 3/8, and so on.

The AN series is also used to specify the thread size and includes the tubing size. Thus, standards like SAE(Society of Automotive Engineers) would apply to AN fittings. Nice tiny system, but one has to get used to a real pain for the newbie!

2. What Is an AN Fitting Size Chart?

Now, let’s talk about the AN fitting size chart—your cheat sheet for making sense of all this. An AN fitting chart lays out the key details: the dash size, the matching tube outer diameter, and the corresponding thread size.

For example, an -8 AN fitting pairs with a 1/2-inch tube and has a thread size of 3/4-16 (meaning 3/4-inch diameter with 16 threads per inch). Then there’s the AN thread size chart, which zooms in on the thread specs alone, helping you match fittings to hoses or adapters without guesswork.

Here’s a quick peek at what you might see on an AN-fitting size chart:

- -3 AN: Tube OD 3/16”, Thread 3/8-24

- -6 AN: Tube OD 3/8”, Thread 9/16-18

- -10 AN: Tube OD 5/8”, Thread 7/8-14

Why does this matter? Imagine you’re plumbing a custom oil cooler. Pick the wrong size, and you’re looking at leaks, pressure drops, or worse—system failure. The chart is your roadmap to getting it right.

The beauty of the AN fitting chart is its consistency. Whether you’re buying from a big-name brand or a local hydraulic shop, those sizes and threads stay the same. It’s a universal language for gearheads and engineers alike.

| AN Size | Hose Inner diameter/ Tube Outer Diameter |

SAE Thread Size |

| -02 | 1/8 in. | 5/16 in.-24 |

| -3 | 3/16 in. | 3/8 in.-24 |

| -4 | 1/4 in. | 7/16 in.-20 |

| -5 | 5/16 in. | 1/2 in.-20 |

| -6 | 3/8 in. | 9/16 in.-18 |

| -8 | 1/2 in. | 3/4 in.-16 |

| -10 | 5/8 in. | 7/8 in.-14 |

| -12 | 3/4 in. | 11/16 in.-12 |

| -16 | 1 in. | 15/16 in.-12 |

| -20 | 11/4 in. | 15/8 in.-12 |

| -24 | 11/2 in. | 17/8 in.-12 |

| -28 | 13/4 in. | 21/4 in.-12 |

| -32 | 2 in. | 21/2 in.-12 |

3. What Materials Are Used for an AN Fitting?

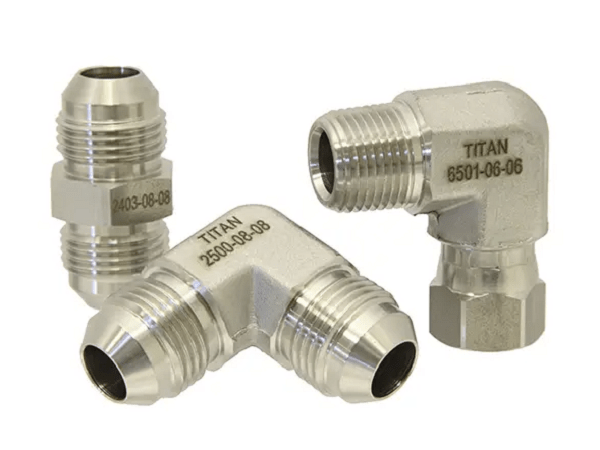

AN fittings aren’t just about size—they’re built to last, and that comes down to the materials. Most commonly, you’ll find them made from aluminum, stainless steel, or brass. Each has its vibe and purpose.

Aluminum is the lightweight champ. It’s easy to work with, resists corrosion pretty well (thanks to anodizing), and comes in cool colors like blue or red. It’s perfect for racing setups where every ounce counts, but it’s not the most demanding guy on the block—high-pressure systems can wear it down over time.

Stainless steel, however, is the heavyweight champion- very durable, very much impervious to corrosion, and able to withstand extreme amounts of pressure and high heat.

But the downside? It's heavier and costs more. For instance, reach more for stainless if it's even the subject of a brake line, a good deal-critical work. Brass is even rarer, but it's one middle ground.

It's really not quite that corroded, but it's a bit easier to machine and much more affordable than stainless. It would be found in low-pressure applications like fuel or water lines; however, it does not stand up to anything intense.

4. What Is the Application of an AN Fitting?

So, where do these fittings shine? The application of an AN fitting is vast, thanks to its versatility and bombproof design. Initially, they were all about aircraft—think fuel lines, hydraulic systems, and oil coolers buzzing through the sky. That aerospace DNA means they’re built to handle harsh conditions without flinching.

In the automotive world, AN fittings are a staple for performance builds. Fuel systems, turbo oil lines, coolant setups—you name it, they’re there. Racers love them because they’re reliable under high pressure and vibration, and they’re easy to swap out when you’re tweaking a setup between runs. -6 AN fittings on a custom fuel rail have been rock-solid, even with ethanol-blended gas.

Beyond cars and planes, you’ll spot them in boats, motorcycles, and even industrial gear. Anywhere you need a flexible, leak-free connection for fluids or gases, AN fittings step up. They’re not cheap compared to basic hardware store stuff, but when failure isn’t an option, they’re worth every penny.

Conclusion

Wrapping this up, the AN fitting size chart is more than just a list of numbers—it’s your key to mastering a system that’s been trusted for decades. Whether you’re sorting out AN fitting sizes like -4 or -16 or digging into the AN fitting dimensions for a perfect match, it’s all about precision and reliability. These fittings, born from military specs, have evolved into a must-have for anyone serious about performance or safety.

The materials—aluminum, stainless steel, brass—give you options to fit your needs, whether you’re chasing lightweight speed or rugged longevity. And the applications of AN fittings? They’re as broad as your imagination, from screaming race cars to high-flying jets.

Next time you’re staring down a project, grab that AN fitting chart, double-check your AN thread size chart, and pick the right tool for the job. It’s not just about getting it done—it’s about getting it done right.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours