Seamless Pipe vs Welded Pipe

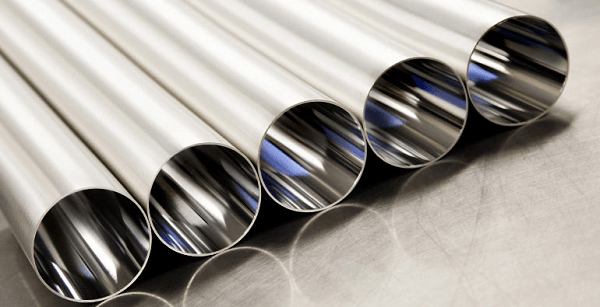

1. What is Seamless pipe?

The tube manufacturing process without seams at any point results in a product known as a seamless pipe that maintains uniformity.

The production method of this pipe involves solid billet piercing to make a tube, which demonstrates exceptional strength properties and structural durability.

Seamless pipe sizes work excellently as high-pressure and high-temperature components within the oil and gas industry, as well as power and construction.

A seamless pipe outperforms seam pipes because it lacks welding seams, which produce weak points, leading to improved stress efficiency.

The reliability and trustworthy nature of seamless pipes originates from the union of precision and safety protocol in their purpose. Seamless pipe meaning exist in multiple dimensions from instrument sizes to industrial scales and are available as steel products that include carbon steel as well as stainless steel.

2. Seamless pipe applications

The diverse manufacturing sector depends heavily on seamless steel pipes because these pipes deliver superior strength with precise engineering capabilities along with extended operational durability.

Through advanced seamless pipeline manufacturing technology, these stainless steel or carbon steel products have a structured structure free of welded joints, which boosts their ability to endure harsh pressure and environmental elements.

Due to their unique properties, they are selected for several applications.

· Oil & Gas Industry

The oil and gas industry and downhole applications, together with drilling operations, utilize seamless pipes as their primary material choice.

Their potent characteristics, together with resistance to high pressure, enable them to serve as optimal materials for harsh fields where pipeline casings and tubing applications exist.

· Power Generation

The power generation sector employs seamless pipes across their boilers and heat exchangers, as well as in steam line operations.

High temperatures and external pressures do not limit seamless pipe sizes as they maintain operational safety through continuous power generation activities.

· Chemical & Petrochemical Industry

Seamless pipes maintain corrosion resistance and deliver smooth interiors, thus enabling them to transport aggressive chemicals and gases securely with minimal contamination.

· Automotive and Mechanical Engineering

The strength, alongside the precision properties of seamless pipes, enables their usage as crucial parts in drive shafts and fuel lines, and hydraulic cylinders of automotive systems and machinery.

· Construction and Infrastructure

Seamless pipe manufacturing process demonstrates outstanding strength capabilities, along with seamless joining that allows them to work within building foundations as well as bridges and industrial buildings for structural reinforcement.

· Hydraulic and Instrumentation Systems

Refrigeration platforms and control instruments use smaller seamless pipe sizes to ensure both exact specifications and leak-proof delivery systems.

3. What is a welded pipe?

The process to make a welded pipe starts with flat steel rolling into a cylindrical profile that requires edge welding to create a unified solid pipe. Inspection procedures apply strenuous tests to evaluate the steel-based seam that results from the welding process, which extends throughout the entire pipe length.

Welded pipes serve multiple industrial purposes because they exist in construction sites and supply systems and oil facilities, and chemical treatment operations.

Manufacturing techniques for welded pipes remain simpler than seamless ones, along with corresponding material expenses, which leads to diminished overall costs. Welded pipes exist as versatile construction components because manufacturers provide them in many dimensions and varieties of thicknesses.

Advances in welding techniques have greatly strengthened and enhanced the performance attributes of welded pipes.

Modern industries employ welded pipes across low and high-pressure operations because these materials demonstrate top-tier reliability in addition to durability and performance capabilities.

Seamless pipes have both corrosion protection and smooth surface properties, which let them transport aggressive chemicals and gases with high security while preventing unnecessary contamination.

4. Welded pipe applications

Various industries utilize welded pipe fittings because of their economic benefits, along with superior strength properties and adaptable nature. The applications that utilize welded pipes include the following:

· Construction and Infrastructure

The structural properties of welded pipes make them suitable for all plumbing work, as well as drainage purposes and water distribution systems.

Welded pipes supply the perfect combination of installation convenience and pressure-bearing capability, thus being appropriate for all types of construction activities from households to businesses and factories.

· Oil and Gas Industry

Users adopt welded pipes to move oil and natural gas products across low to medium-pressure networks. Welded pipe fittings connect to pipes to construct systems with complete structural integrity and leak prevention capabilities.

· Water and Wastewater Systems

The water treatment sector, along with sewage systems together with municipal water distribution systems, favors welded pipes for their operational needs.

These materials show two important characteristics: high resistance to corrosion and excellent strength during pressure applications, which makes them ideal for safely moving water between locations.

· Chemical and Petrochemical Industries

Industrial facilities commonly employ welded pipes to transport various fluid and gas materials between different sections of their chemical plants.

Secure leak-proof connections are ensured through welded pipe fittings, which function effectively in high-temperature or high-pressure situations.

· Agriculture and Irrigation

The irrigation system benefits from using these pipes because they offer reliable operation over time due to their long-lasting properties and simple maintenance requirements.

The use of welded pipe fittings enables welded pipes to join together quickly and allows modifications and lengthening of such pipes, which delivers dependable performance in multiple applications.

5. How to choose welded pipe or seamless pipe for Your Application?

Your particular application demands consideration of pressure along with temperature requirements, as well as cost and strength needs, to determine whether you should use either welded pipe or seamless pipe.

Knowledge about welded pipe vs seamless pipe helps engineers select appropriate pipe types for their projects.

· Pressure and Strength Requirements

The widespread application of seamless pipes in high-pressure systems happens because the pipes maintain maximum resistance to internal pressurization due to having no welded joints.

Seamless pipes prove to be better for projects requiring both extreme stress along high-pressure environmental conditions.

· Cost Considerations

The manufacturing costs of welded pipes remain less expensive than the costs of seamless pipes. The price of welded pipes remains lower during production when considering large construction initiatives and other situations that prioritize cost-effectiveness.

Seamless pipes deliver better durability while achieving higher performance standards in demanding environments, thus their increased pricing makes sense for specific situations.

· Application Temperature

Seamless pipelines prove most suitable for high-temperature functions that involve boiler systems or steam infrastructure. Thermal expansion affects welded pipes less frequently because they lack a seam, which provides better heat resistance.

· Corrosion and Durability

Welded pipes function adequately at medium to low pressure points and in non-corrosive environments. Branch pipes installed in demanding chemical environments perform better when made seamless than those with welded seams.

· Size and Availability

The broad spectrum of welded pipe dimensions as well as thicknesses renders them suitable for various general engineering requirements. Seamless pipes exist in standard sizes, but their main purpose is to serve applications that need precise tolerance values and heightened strength requirements.

The difference between welded vs seamless pipes requires a basic comparison of their characteristics, since the acquired knowledge helps determine specific project requirements.

Conclusion

Different industrial needs demand separate advantages between welded and seamless pipes, which determine the best pipe type selection for an application.

Seamless pipes possess exceptional strength properties, together with high-pressure tolerance and uniform material features that excel under demanding high-stress and high-temperature situations.

Welded pipes provide better cost-effectiveness combined with broad availability, which makes them suitable for operations that do not exceed low to medium pressure levels. The understanding of seamless versus welded pipe differences helps you select the best option between performance requirements and budget limitations, and project needs.

The pressure, alongside temperature and corrosion resistance, and adherence to industry standards, must be evaluated for choosing the appropriate pipe type.

Don't forget to share this post!

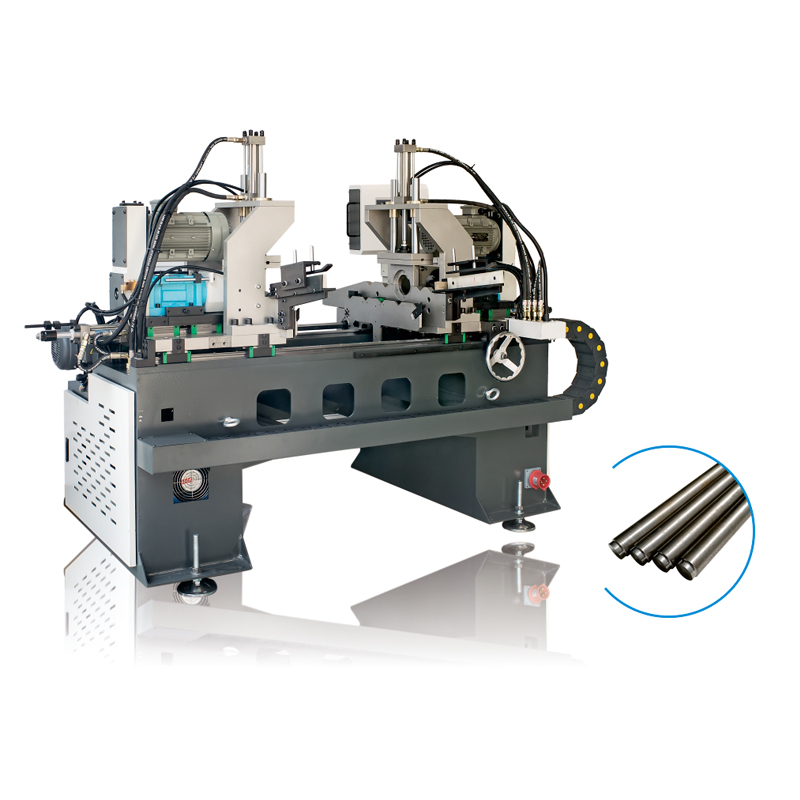

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours