Butt Weld Size & Guide: Everything You Need to Know

Introduction

If you have ever stared at a well-joined piece of metal and asked, "How on earth do they make it so clean?" then you aren't alone. Welding is quite a tough and gritty job, but it is also where precision and strength meet in beauty.

Whether you're in construction, manufacturing, or just geeking over solid metalwork, understanding how metals are fused is more than shop talk; it is necessary.

And one of the most common and trusted ways to connect metals? Butt welding. Before delving into the technicals, let us establish the basics and show why butt welding is the method most chosen by the pros who mean business.

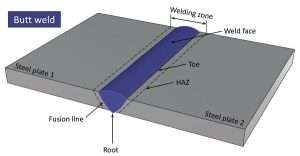

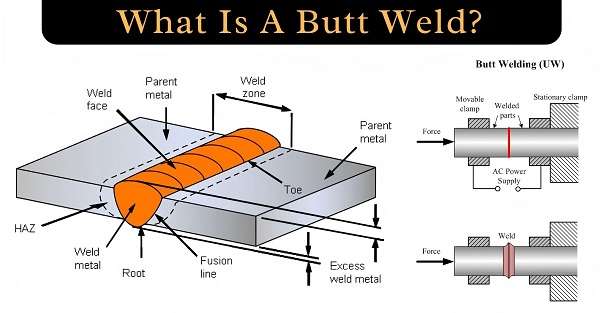

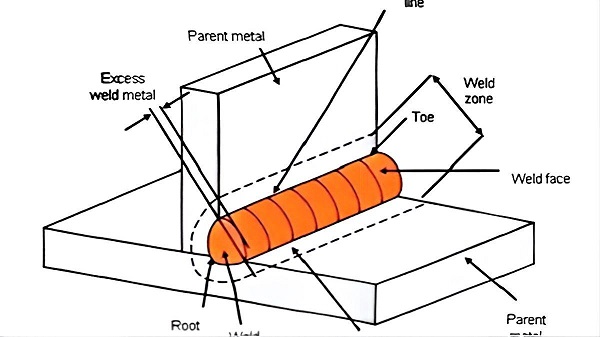

1. What Is The Butt Weld?

Right, let's clear this up: What is a butt weld? It is one of the most common and essential ways of joining two metal pieces end-to-end in the same plane. Think of it like a metal high-five that's been fused forever.

In the world of metal fabrication, butt welds are neat, strong, and highly effective. They come in different forms, which brings us to the many types of welds out there. From square butt welds to bevel grooves, U grooves, and J grooves styles, each one serves a different structural purpose.

And how do you make sure your butt weld is correctly understood on paper? Enter the butt weld symbol. It's that little marking on technical drawings that tells your welders exactly what kind of weld to make. No guessing, no "hope this works"—just clear communication.

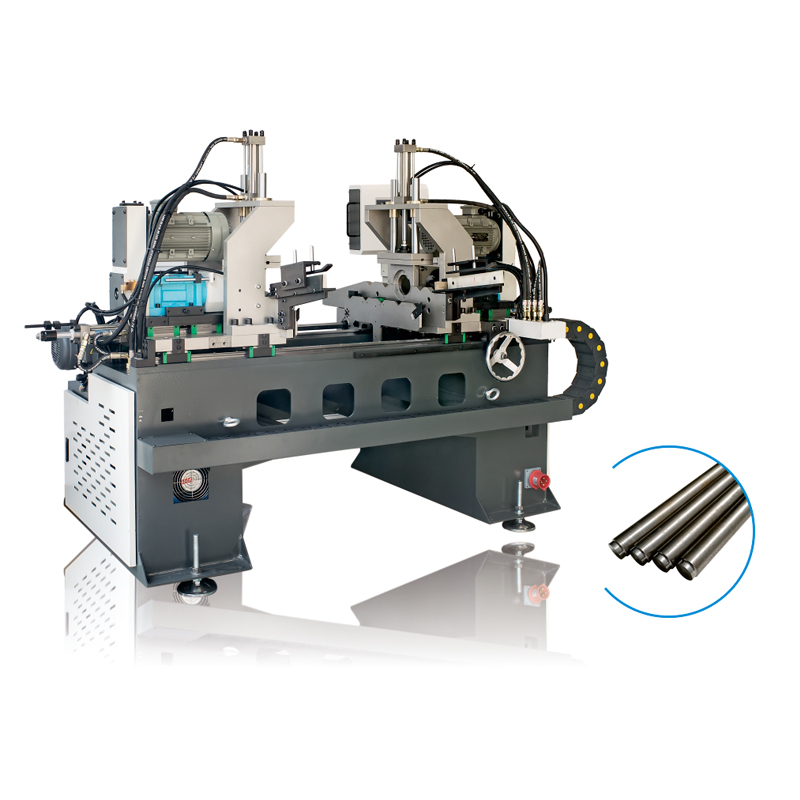

As for how it's done? That's where a butt welding machine comes in handy. Butt welding machine is designed to do the job faster, safer, and more precisely than old-school manual techniques. Perfect alignment, clean fusion, and minimal fuss? Yes, please.

2. What Is The Butt Weld Size Chart?

So, you're staring at a blueprint and thinking: how thick should this weld actually be? That's where the butt weld size chart comes to the rescue.

A butt weld size chart gives you all the essential dimensions for weld thickness based on the materials you're joining. It includes root openings, groove angles, and reinforcement height—basically, the geometry that makes your weld structurally sound.

Here's the thing: getting the size right isn't just about looking fancy on a chart. It impacts the strength, durability, and longevity of your entire build. Oversized? You waste material and money. Undersized? Say hello to failed joints.

3. What Materials Are Used For Butt Weld?

Let's talk metal. Or rather, which ones play nice in a butt-weld situation? The beauty of a butt weld is its versatility—you can use it with a range of materials, including:

- Carbon steel (a classic go-to)

- Stainless steel (for corrosion resistance)

- Aluminum (lightweight but tricky)

- Titanium (for high-end projects)

- Copper alloys (conductive and beautiful)

Each of these metals behaves a little differently under heat, which is why your choice of filler material and settings on your butt welding machine matter big time.

| Weld No. |

MLO (mm) |

Actual (mm) |

Ferrite (%) |

Hardness (HV) |

| 1 | 3.10 | 3.14 | 0.27 | 234 |

| 2 | 3.33 | 3.51 | 0.28 | 261 |

| 3 | 4.48 | 4.12 | 0.00 | 225 |

| 4 | 3.10 | 3.41 | 0.32 | 265 |

| 5 | 4.16 | 4.14 | 0.21 | 293 |

| 6 | 5.34 | 4.98 | 0.00 | 255 |

| 7 | 3.23 | 3.37 | 0.33 | 179 |

| 8 | 3.76 | 3.68 | 0.21 | 174 |

| 9 | 4.02 | 4.14 | 0.00 | 203 |

| 10 | 2.95 | 3.18 | 0.36 | 232 |

| 11 | 4.30 | 4.04 | 0.29 | 218 |

| 12 | 4.44 | 4.28 | 0.00 | 211 |

4. What Is The Application Of The Butt Weld?

Where do butt welds show up in real life? Short answer: everywhere. Long answer? Let's break it down.

Butt welds are found in:

- Pipelines (oil, gas, water—you name it)

- Structural steel fabrication

- Shipbuilding and offshore structures

- Pressure vessels and boilers

- Automotive manufacturing

- Aerospace components

Why would anyone consider this instead of other types of welding? It has much strength for very little volume, which is important when you want to keep it light or aerodynamic.

There's another advantage: it's easier to check a good butt weld by X-ray or ultrasound testing, which is a winner where safety compliance is concerned.

5. What Are Butt Weld Standards?

Nobody likes rogue welds. That's why the welding world follows strict standards to make sure your butt weld doesn't go off-script.

Globally recognized butt weld standards include:

- ASME Section IX

- AWS D1.1 (Structural Welding Code)

- ISO 9606

- EN 287

- API 1104 (for pipelines)

Everything, right from procedure to qualifications of the welder, comes under these standards to ensure quality and safety, thus abiding by integrity across various industries.

Butt welding machine setups are compatible with WPS and PQR documentation while improving still mostly how compliant your flow is. Your next audit? A total breeze.

6. How To Choose The Right Butt Weld?

Choosing the right butt weld depends on several juicy factors:

- Material type and thickness

- Joint configuration

- Load requirements

- Access to both sides of the joint

- Desired finish (because sometimes looks do matter)

If your parts are thick or need to bear heavy loads, go for a full penetration weld with a proper bevel or U-groove. If you need a fast and simple connection, a square butt might do just fine.

The real trick? Match the job to the right butt welding machine. The right machines offer adjustability, automation, and easy programming, so you're never stuck with a one-size-fits-none setup.

Conclusion

Butt Weld is not just a metal joint, but the unsung hero in pipelines, pressure vessels, bridges, and anything else that can't afford to fall apart.

From decoding the butt weld symbol to checking the butt weld size chart, every step matters. The material you select must fit well for its intended use, and the standard that you observe- everything has to match well. Choosing the right tool for the job isn't merely welding; it's evaluating the workflow while chopping down downtime and securing serious quality.

So, whether you build skyscrapers or submarines, at the end of the day, your welds are only as good as your process. With the right knowledge, tools, and technique, you get brains, brawn, and boldness all tied in one weld. So that the next time someone asks, "What is a butt weld?" you'll not only have the answer-you'll own it.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours