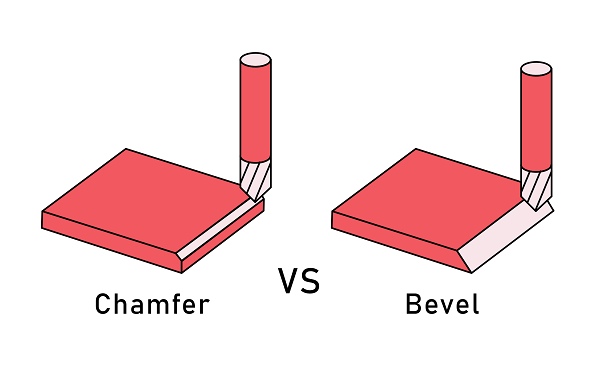

Chamfer vs Bevel :What’s the Difference?

Introduction

To ensure you have the best finish on materials, whether you are woodworking, metalworking, or doing construction, you must differentiate between chamfer and bevel. Both concern cuts and edges, but they will never be a replacement for one another. Both chamfering and beveling degrade sharp edges and enhance safety, but the actual application of the two differs.

Understanding the meaning of chamfer and bevel will aid you in selecting the appropriate edge treatment for your project. Product design, furniture, or a worthy edge makes a whole lot of difference in the outcome of any project.

Let’s discuss chamfer and bevel, their applications, and the considerations for choosing one for your application.

1. What is Chamfer?

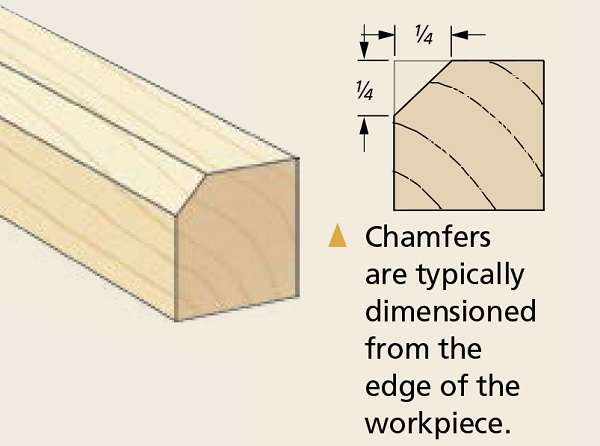

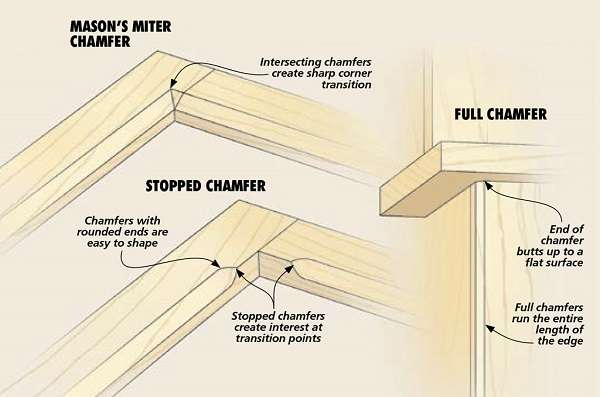

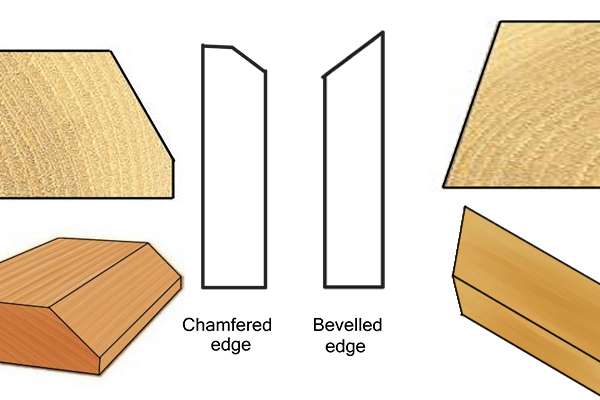

To start with, we will first discuss chamfer's meaning. A chamfer is defined as an angle which is cut at the edge or corner of a part, usually at 45 degrees, but has some variations in it. The purpose of the chamfer is very simple: to make the part safer by removing sharp corners or edges and making it easier to fit with other pieces.

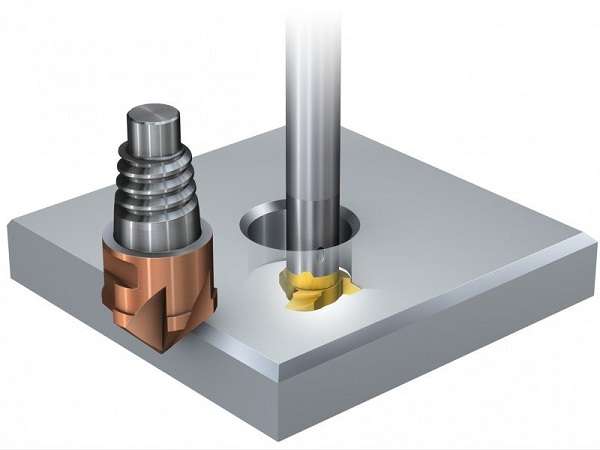

For clean and safe edges, a chamfer system will be used in industries like manufacturing, construction, and even woodworking. A professional finish for your project comes from consistency through and through for all parts or edges, and this system ensures chamfering for all of them combined.

The chamfer system becomes essential during projects where precision and safety matters. Assembly with such parts needs to ensure a smooth fit or prepare metal for threading, making all the involved processes easier and safer with a chamfer.

Using a chamfer system guarantees that every part has the same angle and that your project will achieve consistency and uniformity.

2. Chamfer Application

Who uses the chamfer system? The simple answer: professionals in many industries.

Here are just some relevant examples of chamfer uses:

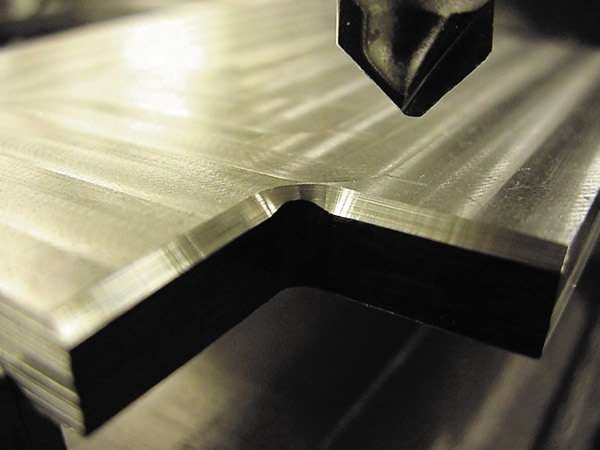

- Machinists: Prepping holes and edges for assembly or threading, especially useful for creating pieces that will fit together within complex assemblies.

- Engineers: Generally, a chamfer is included in CAD designs for easy assembly and protection from damaging parts.

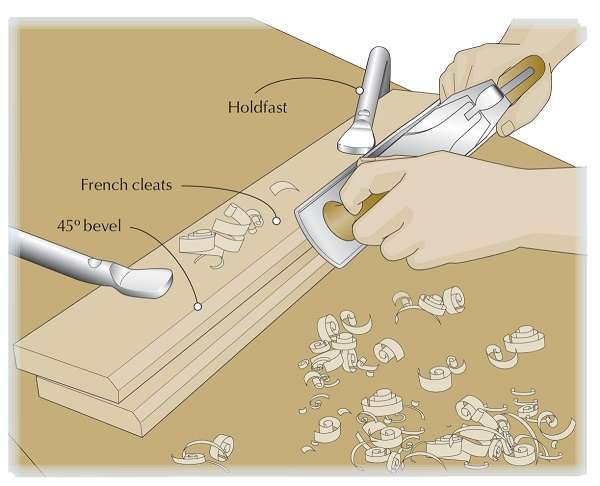

- Woodworkers: Using the chamfer system can also eliminate sharp edges on wooden furniture or doors, rendering edges have a safe and eye pleasing appeal to them.

- Tilers: With a chamfer, it is ensured to keep the edges of tiles from chipping when installed, yet also provide a cleaner finish in the look of the joints.

- Metal workers:Edges of metals are chamfered or bevelled to prepare the surfaces for welding so that the edges come together smoothly.

Chamfer systems can also be useful in DIY. Be it a new table or two metal pieces being put together, having a chamfered edge allows everything to work more easily and safely. Less risk of injury and a cleaner fit are possible by eliminating gaps; likewise, the functions of the project serve functional and aesthetic purposes on top of everything else.

3. What is Bevel?

Now, let’s move on to bevel. A bevel is also an angled cut, but the only difference between bevel vs chamfer is that the bevel is deeper and more gradual than a chamfer. Where a chamfer is almost always fixed at an angle, a bevel may have variable angles between the two according to the design and function of the piece.

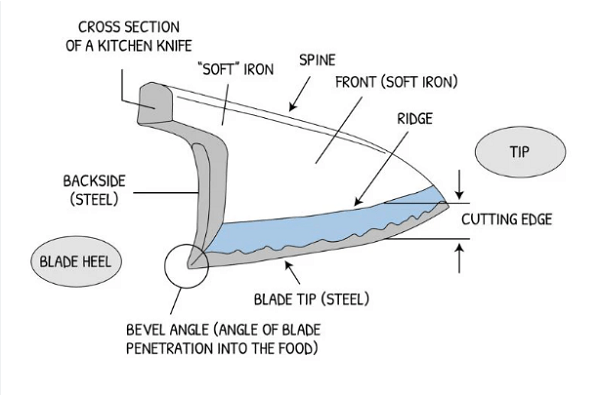

Bevel cuts are generally made for tools and materials which are important in strength and precision. For example, blades and tools like knives and chisels have their edges bevelled to allow for a sharp cutting edge due to the angle.

To change the profile of a material, an edge is bevelled, while a chamfer would only take a little off the edge. The angle is often more gradual, which allows for much finer control over the final edge shape.

A bevel is perfect for a functional edge, but goes beyond just that. Whether you want to make a blade edge, add strength to a joint, or even just be a little fancy with things, a bevel cut can take care of all those for you.

4. Bevel Application

So, where are bevels used? Bevel applications are vast and varied.

Here are some of the most common uses of bevel:

- Blades and knives:The bevel cut is sharp enough to provide a blade its sharp edge. Without the bevel, it would be hard to apply the precision cut which is a mandatory requirement in many such tools.

- Welded joints:A bevel is used in welding for edges prepared to receive a strong joint. The edges are brought together, ready for welding, and strong for the joint to be installed.

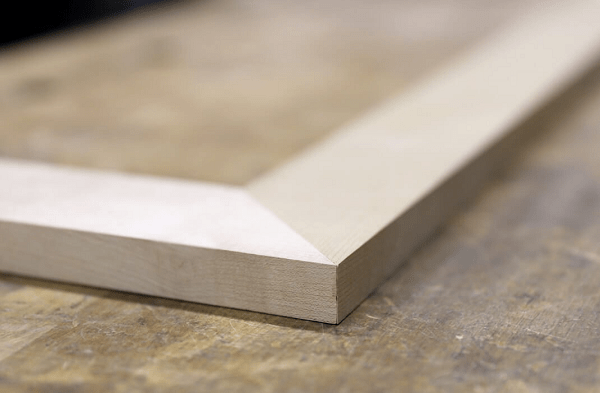

- Woodworking: Bevels can make a seamless transition in a piece of furniture, a cabinet, or flooring, leaving a polished edge in woodworking projects.

- Glasswork: Decorative applications are typically applied using bevels to mirrors or glass-finish furniture. Given the angle, it provides a more elegant look, infusing the edge of the glass with depth.

- Architecture:Bevels can be used at the junction of materials in architecture, such as where a wall or window edges meet.

The beauty of bevels is that they can do both. You can design for strength or aesthetics, and then bevel gives you the flexibility that you need to get just the right edge for your application.

5. How do you choose Bevel or Chamfer for your application?

Choosing between bevel vs chamfer mainly depends on the use of the alleged cut. What's this edge supposed to do? Must it fit in somewhere tight, or does it need to make something stronger or fancier?

Here's the difference between bevel vs chamfer and how to choose between the two, depending on what you want:

| Feature | Chamfer | Bevel |

| Cut Angle | Usually fixed (often 45°) | Varies based on use |

| Depth | Shallow | Deeper and longer |

| Purpose | Safety, ease of assembly | Function (cutting, welding), design |

| Tool | Chamfer system (manual or CNC) | Grinder, sander, or bevelled |

| Common Use | Prepping edges, removing sharpness | Shaping blades, design elements |

Choose Chamfer If:

Chamfers are the way to go if you're trying to get quick edge cleanup. They also work on getting parts to fit properly, such as in assembly lines or when putting two types of material together.

Chamfers are also good at preparing a hole for threading because it makes putting threads in easier. Finally, a chamfer is ideal for any project requiring precise and even angles of 45° because it offers a simple cut that can be counted upon for predictability.

Choose Bevel If:

On the contrary, beveling is preferred when the intention is to create sloping surfaces for the sake of strength or aesthetics. Bevels are required for shaping tooling or cutting blades for angles that require ultimate sharpness and precision.

Bevels can also deliver that stylish look when a more sophisticated finish is in demand. Finally, if there is a need for a custom or graduated angle, the bevel allows for adjusting angles meeting the design specifications.

Conclusion

When weighing bevel versus chamfer, it is crucial to dissect the fine details of project requirements. Both methods accomplish angled edges, but they are fit for entirely different kinds of jobs.

In short, a chamfer provides quick cleaning for a simple edge while ensuring a practically smooth fitting of parts for safety. A chamfer is chiefly applied in machining, woodworking, and construction to remove sharp corners and ease assembly.

A bevel goes the other way with the added measure of versatility and strength. A bevel is suited for applications requiring cutting edges, such as knives or tools, alongside decorative finishes. Be it for strength in a joint or a refined finish for an object, beveling provides not only that polished and sleek aesthetic appeal but also control of the final product.

With a better understanding of the chamfer meaning and the purpose of a bevel, the professional and confident choice of edge treatment best suited for your particular project is assured, functionality first, then esthetics.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024