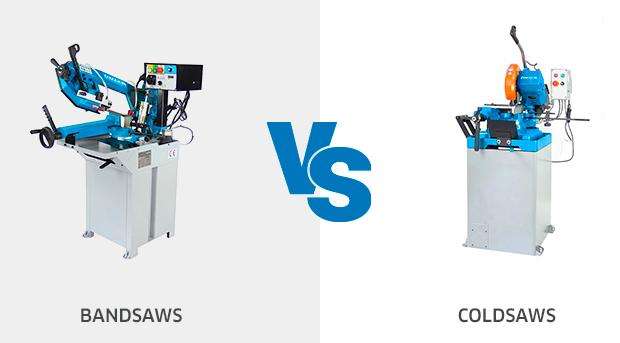

Cold Saw vs Band Saw, What's The Difference?

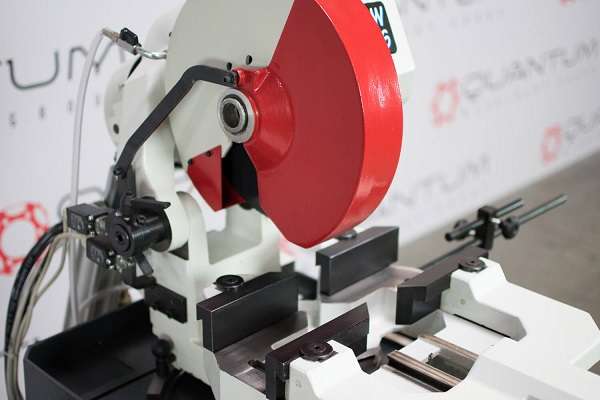

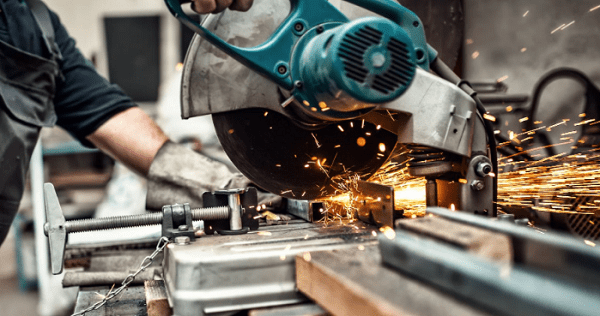

1. What is a cold saw?

A cold saw represents a specific type of circular saw utilized in cutting metal with the highest precision. define cold cut, unlike abrasive saws, produce little heat and sparks.

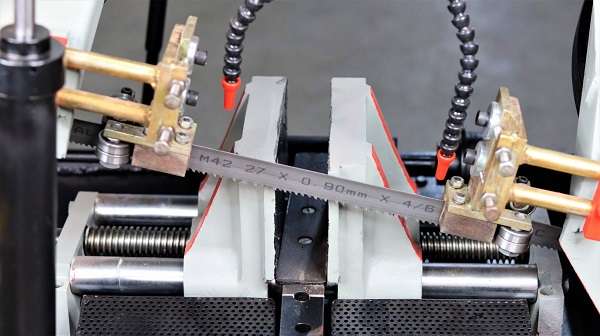

A toothed blade constructed of high-speed stainless steel with carbide-tipped materials is characteristic of cold saws, which contain a cooling system that lowers the cutting temperature. This leads to cleaner, burr free cuts with minimal thermal distortion.

The cold saw's meaning is achieved through its capacity to ensure that the blade and the workpiece are kept cool in the course of the operation.

This is done by conducting the heat into the chips, which are ejected as the blade passes through the material. Cold saws can be found in metal fab shops, manufacturing facilities, or construction sites where precision and clean finishes are necessary.

These saws cut steel, aluminum, and other non-ferrous metals, and are characterized by long blade life and repeat accuracy. A cold saw is an efficient and professional way to go, whatever your cutting requirements are, straight cuts, angled cuts, or repeated cuts.

2. Cold Saw Application: What Does Cold Saw Stand For?

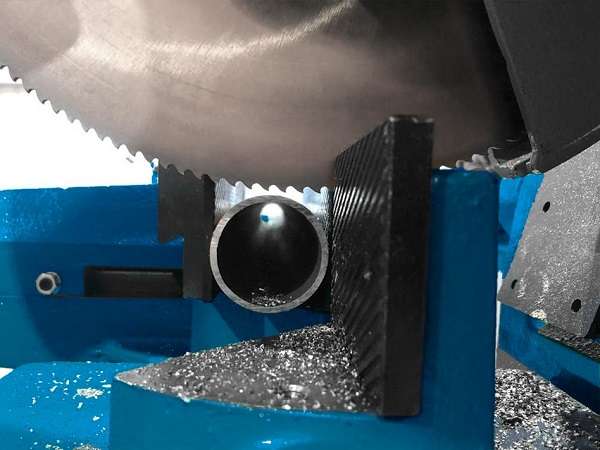

A cold saw represents a type of metal-cutting saw equipped with a circular blade and a coolant system to make clean and precise cuts without producing excessive heat.

In contrast to abrasive saws, cold saws run at low RPM and high torque, which means that they can cut metals without heating the workpiece or the cutting tool excessively.

The applications of cold saws are mostly in metalworking, automotive garages, construction, and factory production. Metals such as steel, aluminum, brass alloy, and copper, as well as non-ferrous metals, are easily cut with them.

Cold saws are particularly appreciated where precision cuts are needed, and where burrs must be avoided as in structural steel cutting, pipe and tubing, and machining components.

Due to the cooling effect of the saw, distortion is minimal, and cold saws are ideal where high precision cuts need to be repeated in both small-scale and heavy-duty applications.

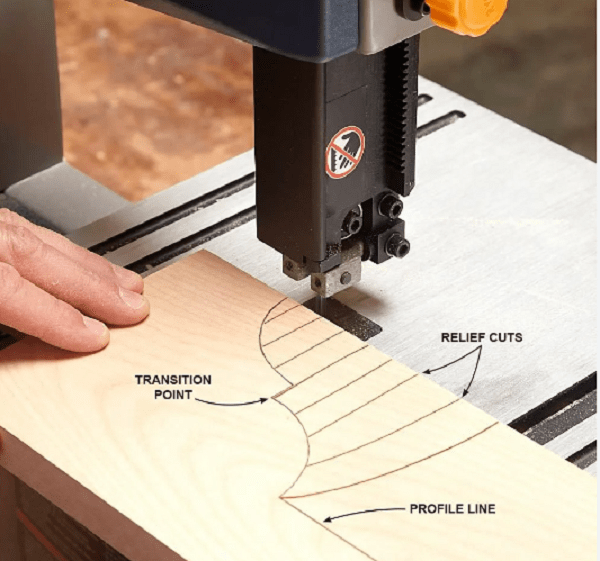

3. What is a band saw?

How to define band saw? It is a heavy-duty cutting machine whose long, continuous blade with sharp teeth is stretched between two or more wheels.

It is programmed to cut accurately, straight, or curved lines on different materials such as wood, metal, and plastic. The blade strokes in one direction and gives even and smooth cutting.

What Does Band Saw Mean?

The band saw is called so because of the band-shaped blade that works in a loop, ensuring that the process of cutting can be done with little downtime.

The blade of the band saw, contrary to the circular saws, runs in a straight line either vertically or horizontally, which is why this tool is appropriate to make a detailed and accurate cut.

Define Band Saw

To better define band saw, we know that A band saw is a flexible power saw that is employed in woodworking, metalworking, and fabrication shops. It is particularly useful.

- Resawing (slicing wide boards into narrow slabs)

- Cutting wood or metal in a curved manner

- It involves cutting odd shapes or angles.

- Accurate trimming and shaping

There are both vertical and horizontal band saws, and both are used in particular jobs and with certain materials. Both are useful to define band saw.

4. Band Saw Application

A band saw application means the numerous applications of a band saw within several industries like woodworking, metalworking, and fabrication. A band saw is accurate and versatile and can make straight, curved, and irregular cuts in various materials.

Common Band Saw Applications

Woodworking

- Cutting lumber into narrower slabs or veneers

- Furniture or craft cutting curves and shapes in wood

- Doing intricate scrollwork and joinery

Metalworking

- High precision cutting of pipes, rods, and metal sheets

- Fabrication cuts at an angle or contour on metalwork

- Little heat generation provides clean cuts with slight distortion

Meat Processing

- Butcher shops and meat plants use industrial-grade band saws to cut large portions of meat and bones

Plastic and Composite Cutting

- Applicable in cutting plastics, fiberglass, and composites in manufacturing

- Guarantees a clear edge finish and less cracking or chipping of materials

Construction and DIY Projects

- Applied on work sites when there is a need to cut wood, metal, or plastic on demand

- Useful when making custom shapes and components when constructing or doing repairs

Accuracy, curve-cutting capability, and versatility are the main reasons why band saws are among the key tools in numerous professional and hobbyist workshops.

5. Cold Saw vs Band Saw, How to choose it for Your Application?

When choosing between cold saw vs band saw, you have to know exactly what you need in terms of cutting.

These two tools are intended and used in industries and workshops, although they are different in terms of purpose, depending on the material to be cut, the quality of the cut, and the production needs.

Circular saw vs band saw: Key Factors to Consider

Type of Material

- Cold Saw:Most suitable when cutting metal, and precision is of utmost importance.

- Band Saw:It is perfect on many different materials, such as wood, metal, and plastic, again depending on the blade.

Cut Quality and Accuracy

- Cold Saw:Yields clean, burr free, square cuts with little finishing.

- Band Saw:Can be used on rough or curved cuts, and might need further finishing for precision work.

Cutting Volume

- Cold Saw:Ideal when a lot of cutting needs to be done repeatedly, and precision is always required.

- Band Saw:More suitable when the cutting work is sometimes or frequently changed, or when Irregular shapes need to be cut.

Budget and Blade Cost

- Cold Saw:Greater price of entry and of blades; however, blade durability and finish are superior.

- Band Saw:Less expensive, less durable blades, though.

Space and Portability

- Cold Saw:Not mobile and needs a specific place of work.

- Band Saw:It comes in portable versions, allowing it to be more job sites or in small shops.

Cold Saw vs Band Saw – Which One Is Right for You?

- Select a cold saw when your need requires clean, accurate cuts in metal and requires repeated operation in high-volume production.

- Choose a band saw when you require flexibility or the capacity to cut various materials and shapes, or have a smaller budget.

These differences between cold saw vs band saw will guide you to make an informed decision when deciding on the most efficient, high-quality, and cost-effective cutting tool to use in your projects.

Conclusion

When deciding between a cold saw vs band saw, the appropriate solution is to select a type that meets your cutting requirements.

Cold saws are best at providing a clean, accurate cut in metal with very little heat and finishing needed- they are well suited to high-volume, industrial uses.

Band saws are however more versatile and can cut a larger variety of materials and in a curved pattern at a cheaper price. When precision and finish are of concern to you, use a cold saw.

Where flexibility and budget are more important, a band saw is more suitable. Choose the right cut quality, material type, and production volumes to make the most appropriate decision for your workshop.

Related Reading

1.cold cut saw vs band saw

If you want to choose, cold cut saw vs band saw, which is better, you can compare the following options to make a choice:

If you have a high pursuit of precision and smoothness, then I suggest you choose a cold cut saw;

If you focus on multi kinetic energy and capacity, then it's best to choose a band saw.

In addition, if you have a large quantity of metal cutting needs, cold cut saws are a more effective choice for you;

If you have a lot of consideration for your budget, there is no doubt that a band saw is more cost-effective

2. circular saw vs band saw

Don't forget to share this post!

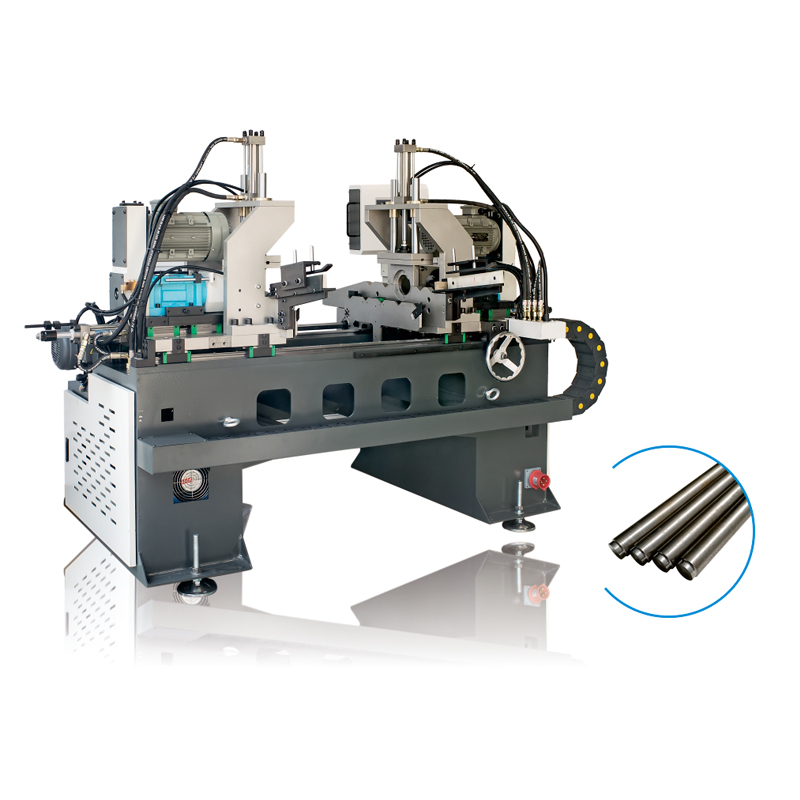

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours