Conduit Size Chart: Types, Applications & Materials

Introduction

When designing an electrical wiring project, selecting the right conduit size is crucial for safety, regulatory compliance, and performance. Electricians, DIYers, and contractors can access conduit size charts to determine the conduit diameter based on factors such as wire type, conductor count, and installation requirements. The correct conduit will offer reliable protection when running wiring behind walls, beneath the soil, or in openly visible areas.

Understanding what conduit components do is just as important. For example, coupling is the fitting that connects two lengths of conduit together to enable longer lines. Along with using the perfect conduit size chart, these things make electrical planning easier and adhere to code. Keep reading to learn more.

1. What is the Conduit?

A conduit is a type of pipe system that surrounds and protects electrical wires in residential, commercial, and industrial settings. Also, it ensures safe wire passage which can mitigate physical damage, moisture exposure, and interference. Conduits are comprised of various materials such as metal, PVC, and flexible plastic, based on the location as well as the application.

A coupling is a component used by electricians to increase the run length of a conduit. Coupling meaning in electrical work refers to the method of connecting two respective pieces of conduit into one continuous channel. That’s even more important when working on large installations or getting through intricate layouts.

What is Conduit Power?

Conduit power is electricity that runs through wires enclosed within a protected casing called a conduit. The conduit does not itself transmit power. It basically just holds the electrical wires. This configuration prevents wires from shock, moisture, and cross-talk. Electrical systems remain protected with conduit methods, allowing for neat installations.

They are used extensively in residential, commercial, and industrial environments. A conduit, whether metal or plastic, conduits guide and protect power lines. They also help with code compliance and make maintenance easier. Conduits provide better electrical protection and longer life. It’s a vital component of modern electrical systems.

What Does a Conduit Do?

A conduit protects electrical wires against physical damage, moisture, and corrosion. It offers protection for wiring installations. It helps keep the organized wires in a single protected channel. They decrease the likelihood of electrical and fire hazards. Conduits provide more protection in wet or outdoor areas.

They also protect against accidental contact with live wires. Conduit helps meet building code requirements. They make future upgrades or repairs easier. They play an essential function in safe, efficient electrical systems.

2. What is the Conduit Size Chart?

In simple words, a conduit size chart is a guideline used to calculate the proper size of conductors for a certain electrical installation. It assists professionals in determining the appropriate diameter based on the wire type, conductor count, and environmental conditions for installation.

The chart considers other parameters, such as wire gauge and conduit material.

A conduit size chart for wire helps to avoid congested wires and facilitates the safe pulling of wires through the conduit. Sizing the conductor appropriately is critical for heat dissipation, limiting damage, and meeting electrical codes.

| Conduit Size (in nches) | ||||||||

| Rigid | ||||||||

| EMT | Conduit | |||||||

| Electrical Metallic Tubing | Steel or Aluminum | |||||||

| Trade | Outside Diameter |

lnside Diameter |

Radius | Outside Diameter |

Inside Diameter |

Radius | ||

| Size | ||||||||

| 1/2 | 0.706 | 0.622 | 0.311 | 0.840 | 0.632 | 0.316 | ||

| 3/4 | 0.922 | 0.824 | 0.412 | 1.050 | 0.836 | 0.418 | ||

| 1 | 1.163 | 1.049 | 0.525 | 1.315 | 1.063 | 0.532 | ||

| 1-1/4 | 1.510 | 1.380 | 0.690 | 1.660 | 1.394 | 0.697 | ||

| 1-1/2 | 1.740 | 1.610 | 0.805 | 1.900 | 1.624 | 0.812 | ||

| 2 | 2.197 | 2.067 | 1.034 | 2.375 | 2.083 | 1.042 | ||

| 2-1/2 | 2.875 | 2.731 | 1.366 | 2.875 | 2.489 | 1.245 | ||

| 3 | 3.500 | 3.356 | 1.678 | 3.500 | 3.090 | 1.545 | ||

| 3-1/2 | 4.000 | 3.834 | 1.917 | 4.000 | 3.570 | 1.785 | ||

| 4 | 4.500 | 4.334 | 2.167 | 4.500 | 4.050 | 2.025 | ||

| 5 | - | - | 5.563 | 5.073 | 2.537 | |||

| 6 | - | 6.625 | 6.093 | 3.047 | ||||

3. What Materials Are Used for Conduit?

Conduit is made from a variety of materials depending on the application and environment. Common types include:

- Steel Conduit:This is tough, long-wearing, and designed for high-impact regions. It has great protection during industrial and commercial installations.

- Aluminum Conduit:Lightweight and corrosion-resistant. A common use is in an outdoor or damp environment where rust may be an issue.

- PVC Conduit:Non-metallic, moisture resistant. Its installation is easy and it is oriented for underground or wet applications.

- EMT (Electrical Metallic Tubing):EMT is a thin-walled steel conduit. It is easy to bend and used in exposed indoor wiring where space is tight.

- Flexible Metal Conduit (FMC):This type of metal conduit is easy to bend which is convenient for use in tight or curved spaces. It makes it easier to shift around regularly.

- Liquid-Tight Flexible Conduit:The conduit is coated to make it waterproof. It’s applied in wet or greasy environments to shield electrical wiring from liquid damage.

4. What is the Application of the Conduit?

Conduits are used in a variety of settings to protect and organize electrical wiring. Common applications include:

- Residential wiring– protects home electrical systems inside walls, ceilings, and basements.

- Commercial buildings– organizes complex electrical networks in offices, malls, and restaurants.

- Industrial facilities – handles high-voltage or hazardous wiring environments.

- Outdoor installations– shields wiring from rain, sunlight, and extreme temperatures.

- Underground wiring– protects buried cables from moisture and soil damage.

- Exposed wiring – provides protection where wires are visible and vulnerable.

- Moist or wet environments– uses water-resistant conduits for kitchens, car washes, or industrial plants.

- Temporary wiring setups– supports safe power routing in events or construction sites.

5.How to Choose the Right Conduit?

The appropriate conduit for your wiring will rely on your specific needs and environment. Keep in mind the following factors:

Installation Environment

Select the conduit based on the location in which it will be used. In wet areas or underground, these are prone to moisture damage. Use PVC or liquid-tight conduits in those areas. These provide great water resistance and are perfect for protecting wires from the environment.

Location

For commercial indoor or exposed areas, the EMT or RMC conduits would work best. They are durable and comply with building codes.

Flexibility Needs

Use Flexible Metal Conduit (FMC) if your installation area has tight turns or equipment movement. It flexes readily and accommodates movement. It is ideal for machinery or arrangements that need periodic movement or adjustment.

Corrosion Resistance

In outdoor or corrosive environments, use aluminum or coated conduits. These materials are strong against rusting and chemicals. They’re perfect for coastal regions, industrial factories, or where wires are exposed to extreme environments.

Wire Capacity

To prevent overcrowding, please refer to a conduit size chart for your wire. It means the conduit needs to be able to have wires fit inside without putting them under stress. Additionally, proper sizing facilitates smoother wire-pulling practices for installation and future upgrades.

Code Requirements

Local electrical code regulations always apply. The codes dictate what type and size of conduit you can use in various applications. Compliance helps ensure safety, legality, passing inspections.

Durability

Use steel or IMC conduits in high traffic or impact risk areas. They are strong and durable. They protect wiring in warehouses, garages, and industrial settings where durability matters.

Conclusion

A conduit size chart helps keep electrical wiring safe and efficient. So, the selection of conduit varies as per the installation process. Location, environment, and code compliance are important considerations. Ensure conduit sections join firmly with a proper coupling. If your wire gets crowded, consult a conduit size chart. This will allow you to make the right and compliant decisions for your electrical system.

For detailed guidance and accurate conduit size, please visit Armpro Machine. Our range of accessories and expert advice ensures that you will find the perfect solution that meets your needs.

Don't forget to share this post!

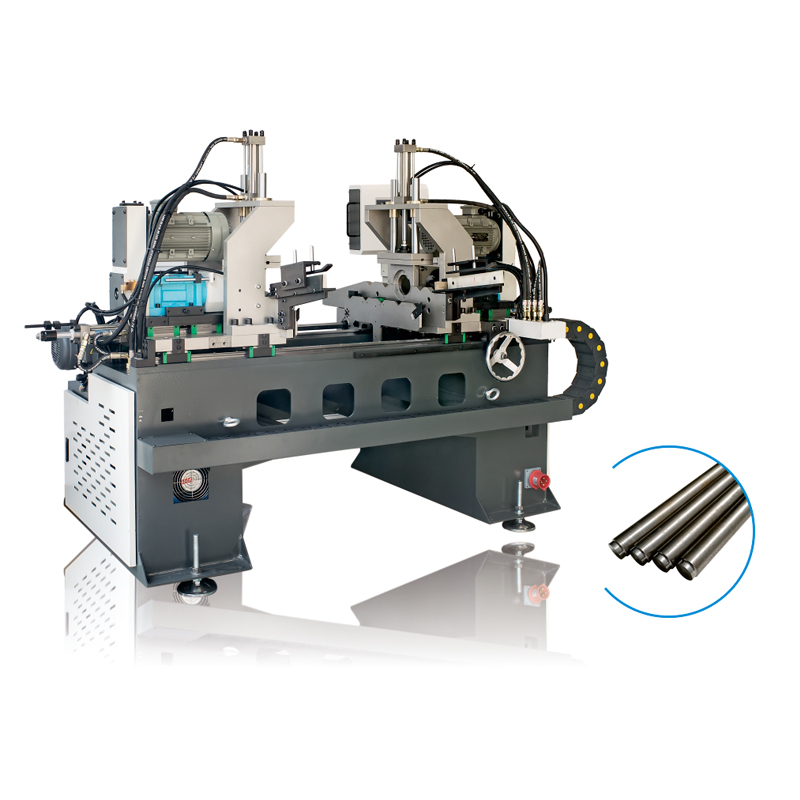

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours