Further Understanding of Copper Tube Size Chart

Introduction

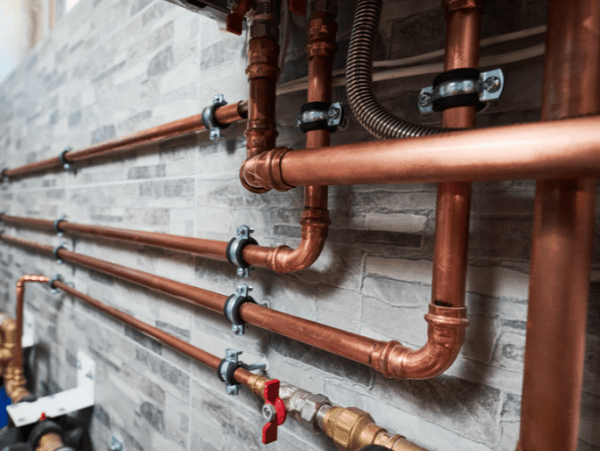

Copper pipes are frequently found in homes and office buildings to carry various fluids. The connections between these pipes are achieved using copper fittings.

Various-sized and shaped fittings are available to properly join pipes. The chart allows people to select the correct fitting for their copper pipes.

Here we’ll cover the basics of copper fittings, how their sizes are chosen, and how to make a proper selection. The information is given in a way that allows everyone to easily understand it.

1. What is the copper pipe size chart?

With the help of a copper pipe size chart or copper fittings size chart, you will be able to determine the copper pipe chart size required for building, plumbing, heating, ventilation, and air conditioning operations.

You must indicate the nominal pipe size, the outer diameter (OD), the surface thickness of the pipe wall, and the type (for instance, K, L, M, and DWV).

Each type has a different wall thickness and use, with Type K being the strongest and thickest. Whether you are a professional or a DIY enthusiast, it is essential to use the copper pipe chart to accurately select the correct pipe for a project involving water, gas, or refrigeration.

The chart prevents the use of fittings that don’t fit with the pipe or fixtures being used. By using the copper pipe size chart or copper fittings size chart, material planning becomes easier, work accuracy improves, and it becomes simpler to follow plumbing regulations.

Regardless of whether you are repairing or replacing copper pipes or working on a new system, the copper pipe chart makes things easier and more reliable.

Here is a basic copper fittings size chart:

| Copper Pipe Fitting Size Chart | |||

| Nominal Size(mm) | Wall Thickness (mm) |

Tolerance +/-(mm) |

Weight (kg/m) |

| 6 | 0.9 | 0.08 | 0.12 |

| 8 | 0.9 | 0.09 | 0.18 |

| 10 | 0.9 | 0.09 | 0.23 |

| 12 | 1.2 | 0.1 | 0.36 |

| 15 | 1.2 | 0.1 | 0.47 |

| 18 | 1.2 | 0.1 | 0.57 |

| 22 | 1.6 | 0.15 | 0.92 |

| 28 | 1.6 | 0.15 | 1.19 |

| 35 | 1.6 | 0.15 | 1.5 |

| 42 | 1.8 | 0.2 | 2.03 |

| 54 | 2.1 | 0.2 | 3.06 |

| 67 | 2.4 | 0.25 | 4.35 |

| 79 | 2.8 | 0.3 | 5.99 |

| 105 | 3.4 | 0.35 | 9.7 |

| 130 | 4 | 0.4 | 14.2 |

| 156 | 4.8 | 0.5 | 20.3 |

| 206 | 6.8 | 0.7 | 38 |

| 257 | 8.5 | 0.85 | 59.3 |

| 308 | 10.3 | 1 | 86.1 |

2. What materials are used for copper pipe?

While high-purity copper is the main ingredient in copper pipes, the presence of some other materials can depend on the purpose and type of pipe. Here's a breakdown of the key materials:

High-Purity Copper (≥99.9%)

- C12200, also known as Electrolytic Tough Pitch (ETP) Copper, is the key material used.

- Due to its good conductivity, anti-corrosion, and formability, copper is perfect for use in plumbing, HVAC, and industrial applications.

Phosphorus (P)

- About 0.015–0.040% of phosphorus is put into the mixture to help deoxidize the copper and increase its strength against corrosion.

- This usually occurs in Type K, L, and M copper pipes that are used for plumbing water and gas systems.

Minor Alloying Elements (Optional)

- Many specialized copper pipes are made with tiny amounts of silver, tin, or arsenic to improve their function, but this is not common in regular plumbing.

With the addition of phosphorus, refined copper in copper pipes becomes durable, does not rust, and is useful for various purposes.

3. What is the application of Copper Pipe?

Everywhere, be it homes, businesses, or industries, copper pipes are very popular because they are strong and resilient, do not corrode easily, and are excellent conductors of heat.

Being able to work under extreme temperatures and pressures means they are valuable for many key systems.

· Plumbing Systems

Copper pipes are found in both types of water supply systems inside homes, buildings, and commercial buildings.

You can typically find Type L or Type M copper pipes being used for these applications. They do not rust, help keep the water clean, and last a long time with very little maintenance.

· HVAC and Refrigeration

Copper’s high conductivity of heat makes it perfect for heating, ventilation, and air conditioning (HVAC) systems. It is commonly found in the refrigerant lines and coils of air conditioning and refrigeration systems.

Heat moves through copper pipes more easily, making the furnace more energy efficient and increasing its output.

· Gas Distribution

For home and business usage, thicker type K copper pipe is used to convey natural gas and propane. It provides a safe, sealing system that follows many building code rules in the community.

· Medical Gas Systems

Gases such as oxygen, nitrous oxide, and others are piped around hospitals and healthcare facilities with copper pipes. They don’t interact with gases and help to maintain the cleanliness and safety of the gases for patients.

· Solar and Hydronic Heating

Copper pipes can be found in solar water heating and radiant floor heating because they conduct and hold heat efficiently.

· Fire Sprinkler Systems

Due to its strength and resistance to corrosion, copper piping is a good choice for dry and pre-action sprinkler systems in areas where steel doors corrode easily.

Copper pipes play a key role in many systems by guaranteeing reliability, efficiency, and a higher degree of safety.

4. How to choose the right copper pipe?

Due to the difference in copper pipe chart sizes, selecting the right copper pipe ensures that your plumbing or HVAC system will be safe, efficient, and durable.

You need to select these based on what you want them for, the necessary pressures and temperatures, and whether you can use them within local building regulations. Here are the steps you need to follow to decide properly:

Identify the Application

The process starts with identifying how the copper pipe will be put to use:

- Plumbing (Water Supply):

Most people choose Type L copper pipe for both homes and businesses since it is reasonably durable and affordable. It can be installed underground or above ground. Since Type M is thinner and less costly, it may be used for the water system at a lower pressure.

- Gas Lines:

Type K copper pipe is usually chosen for the distribution of natural gas or propane. The heavy walls make it the best choice for applications that involve gas pipelines going underground or facing high pressure.

- HVAC and Refrigeration:

Use ACR copper tubing, made for use in refrigerant systems, that is chosen by diameter instead of wall thickness.

- Medical Gas Systems:

For this reason, the United States only uses Type K or L copper pipes that have been thoroughly cleaned and approved.

Understand Copper Pipe Types

- Type K:

Thickest possible; correct for underground water and gas lines or high-pressure pipes, and meets Canadian standards.

- Type L:

The average thickness used in pipes, for use with pipes in the house or above-ground.

- Type M:

Suitable for water systems that do not require high water pressure inside.

- DWV (Drain, Waste, and Vent):

Pipes are used only for draining and venting, since pressure-resistant lines have to be used elsewhere.

Check Local Building Codes

You should always ensure your plumbing and construction codes are met before making a purchase. Certain areas have rules that say what pipe type and size can be used based on the situation to ensure safety.

Determine Pipe Size

Choose a copper pipe size that has the appropriate nominal area and OD to meet the needs of your system. Getting the right size helps the water flow and pressure stay constant.

Consider Budget and Lifespan

Type M pipes can be bought for less, though they are not as sturdy as Schedule 40 and could wear out with high levels of stress or pressure. Type L and Type K pipes are sturdier and suitable for services in stressful sites, lasting longer.

Combining your application needs, durability concerns, rules set by local code, and the costs plays a role in choosing the right copper pipe. When you are unsure, talk to a plumbing expert to make sure your plumbing system is safe, works well, and will last.

Conclusion

A copper pipe size chart helps you pick the suitable copper pipe chart size and type of pipe to ensure proper water flow and the system’s durability.

If you are aware of the differences and qualities of Type K, L, M, and DWV pipes, you can decide on the right pipe for your plumbing, gas, HVAC, or medical gas system.

Always make sure to consider what your application requires, the pressure it faces, the temperature range, and your local building standards.

Using the right-sized and appropriate pipes increases performance and safety, and also helps the system last longer. Make sure to consult an expert and use a proper size chart to get the job done right.

Related Reading

1. copper pipe size chart mm

Perhaps you want to know the copper pipe size chart mm, then I have carried it there. I hope it's useful for you.

| copper pipe size chart mm | |||

| Nominal Size- Tube Outside Diameter(mm) |

Wall Thickness ( mm) |

Tolerance +1-(mm) |

Weight (kg/m) |

| 6 | 0.9 | 0.08 | 0.12 |

| 8 | 0.9 | 0.09 | 0.18 |

| 10 | 0.9 | 0.09 | 0.23 |

| 12 | 1.2 | 0.1 | 0.36 |

| 15 | 1.2 | 0.1 | 0.47 |

| 18 | 1.2 | 0.1 | 0.57 |

| 22 | 1.6 | 0.15 | 0.92 |

| 28 | 1.6 | 0.15 | 1.19 |

| 35 | 1.6 | 0.15 | 1.5 |

| 42 | 1.8 | 0.2 | 2.03 |

| 54 | 2.1 | 0.2 | 3.06 |

| 67 | 2.4 | 0.25 | 4.35 |

| 79 | 2.8 | 0.3 | 5.99 |

| 105 | 3.4 | 0.35 | 9.7 |

| 130 | 4 | 0.4 | 14.2 |

| 156 | 4.8 | 0.5 | 20.3 |

| 206 | 6.8 | 0.7 | 38 |

| 257 | 8.5 | 0.85 | 59.3 |

| 308 | 10.3 | 1 | 86.1 |

Don't forget to share this post!

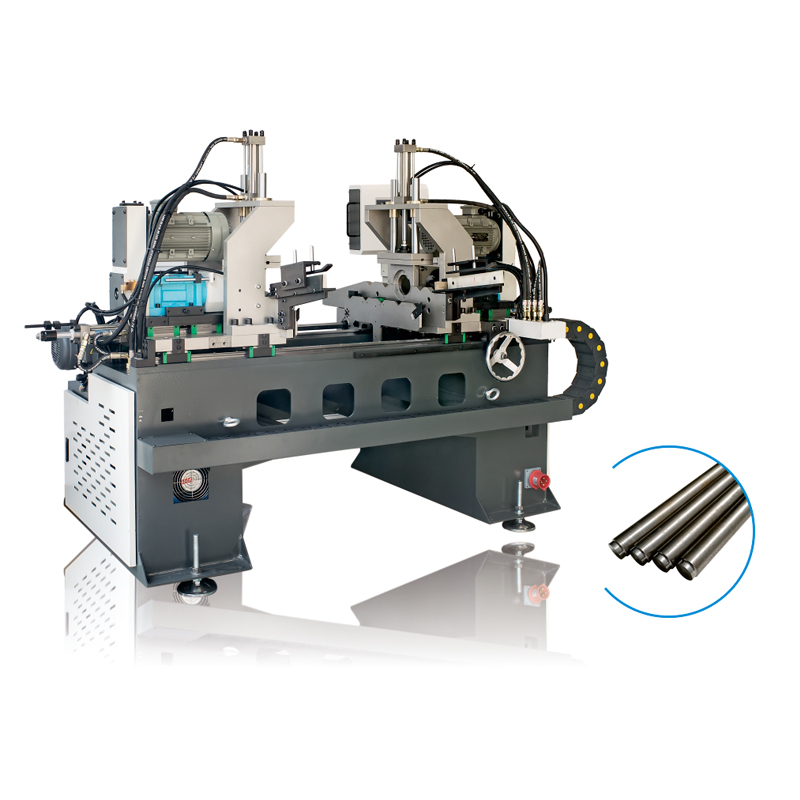

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours