Electrical Conduit Size Chart & Types: Complete Guide for Safe Wiring

Introduction

Selecting the right electrical conduit for residential, commercial, and industrial installations is an important job. All code-compliant electrical systems employ conduits to protect wires from physical damage, moisture, and chemicals. However, there are different electrical conduit types and pipe sizes, so choosing the right one can be confusing.

This is where an electrical conduit size chart comes in handy. It helps electricians, contractors, and DIYers ensure wires fit without exceeding fill capacity limits. For easier and more informed project planning,we will explain electrical conduit size charts、 wire size charts 、wire conduit charts, and various types of conduits in this guide. Keep reading to learn more.

1.What is the Electrical Conduit?

What is the conduit? In short, it’s a type of protective tubing used to route and protect electrical wiring in buildings, machinery, and outdoor installations. An electrical conduit helps protect wires from physical damage, moisture, corrosion, and other environmental hazards.

This also organizes wiring systems and should make upgrading or repairing easier later on.

There are a variety of electrical conduit types, each designed to protect wiring in the ideal environment. Which kind of conduit is appropriate depends on your location, exposure, and convenience of installation.

Types of Electrical Conduit

The types of electrical conduit,there are several electrical conduit types, each suited to different environments and wiring needs:

- Rigid Metal Conduit (RMC): The first types of electrical conduit we introduced is a strong and very stiff metal electrical conduit favorable for outdoor and industrial installations.

- Electrical Metallic Tubing (EMT): EMT is a lightweight metal electrical conduit that’s very common in commercial settings because of its ease of installation.

- Flexible Metal Conduit (FMC): FMC is typically used around motors and machines and offers flexibility for tight and curved spaces.

- Electrical conduits PVC:Best suited for underground or wet locations, this non metallic PVC option is corrosion resistant. Also, due to its lightweight and easy to cut nature, it has grown popular among residential users.

- Liquid-tight Flexible Conduit (LFMC): Perfect for harsh or wet environments, as this is designed to repel moisture, oil, and chemicals.

2. What is the Electrical Conduit Size Chart?

An electric conduit size chart or wire size chart is a quick reference tool that lists standard electrical conduit pipe sizes and wire fill capacities. It’s a must-have for electricians, contractors, and DIYers looking to ensure their wiring inside conduit pipes is safe and efficient. Understanding what an electrical conduit is and the size of conduit pipe goes beyond just knowing its purpose—it includes knowing how to size it correctly, and get the right size of conduit pipe

| Trade Size | Nominal Internal Diameter | Total Area 100% |

60% | 1 Wire 53% |

2 Wires 31% |

Over 2 Wires 40% |

||||||

| mm | in. | mm² | in.² | mm² | in.2 | mm² | in.? | mm² | in.2 | mm² | in.² | |

| % | 15.3 | 0.602 | 184 | 0.285 | 110 | 0.171 | 98 | 0.151 | 57 | 0.088 | 74 | 0.114 |

| % | 20.4 | 0.804 | 327 | 0.508 | 196 | 0.305 | 173 | 0.269 | 101 | 0.157 | 131 | 0.203 |

| 1 | 26.1 | 1.029 | 535 | 0.832 | 321 | 0.499 | 284 | 0.441 | 166 | 0.258 | 214 | 0.333 |

| 1% | 34.5 | 1.360 | 935 | 1.453 | 561 | 0.872 | 496 | 0.770 | 290 | 0.450 | 374 | 0.581 |

| 1% | 40.4 | 1.590 | 1282 | 1.986 | 769 | 1.192 | 679 | 1.053 | 397 | 0.616 | 513 | 0.794 |

| 2 | 52.0 | 2.047 | 2124 | 3.291 | 1274 | 1.975 | 1126 | 1.744 | 658 | 1.020 | 850 | 1.316 |

| 2Y | 62.1 | 2.445 | 3029 | 4.695 | 1817 | 2.817 | 1605 | 2.488 | 939 | 1.455 | 1212 | 1.878 |

| 3 | 77.3 | 3.042 | 4693 | 7.268 | 2816 | 4.361 | 2487 | 3.852 | 1455 | 2.253 | 1877 | 2.907 |

| 3% | 89.4 | 3.521 | 6277 | 9.737 | 3766 | 5.842 | 3327 | 5.161 | 1946 | 3.018 | 2511 | 3.895 |

| 4 | 101.5 | 3.998 | 8091 | 12.554 | 4855 | 7.532 | 4288 | 6.654 | 2508 | 3.892 | 3236 | 5.022 |

| 5 | 127.4 | 5.016 | 12748 | 19.761 | 7649 | 11.857 | 6756 | 10.473 | 3952 | 6.126 | 5099 | 7.904 |

| 6 | 153.2 | 6.031 | 18433 | 28.567 | 11060 | 17.140 | 9769 | 15.141 | 5714 | 8.856 | 7373 | 11.427 |

Using the wrong size causes overheating, difficulty pulling wires, or code violations. This chart helps determine the sizes of electrical conduit pipes that can contain different amounts of wires and their gauges. Whether you're installing a single circuit or running several cables, the chart helps you choose the right size.

3. What Materials are Used for Electrical Conduit?

Different installation environments and requirements determine the material used to make each electrical conduit. Here are the most common materials used:

- Galvanized Steel: A thick, strong, and heavy-duty metal that is used for rigid metal conduit (RMC) and is ideal for any outdoor and industrial scenarios.

- Aluminum: Lighter than steel, aluminum is also corrosion-resistant, making it suitable in areas with moisture exposure.

- Stainless steel: Provides excellent corrosion resistance, suitable for harsh or chemical environments.

- PVC (Polyvinyl Chloride): Electrical conduit PVC is a quick and simple-to-work material that is excellent for underground and wet applications.

- HDPE (High-Density Polyethylene): HDPE conduit is flexible and durable and is commonly used for telecommunications and buried electrical lines.

- Fiberglass: Non-conductive and corrosion-resistant, fiberglass conduit is well-suited to high-temperature or corrosive environments.

- Nylon and Other Plastics: Used in flexible conduit types where flexibility and chemical resistance are needed.

Professionals can select the right material according to safety, durability, and code compliance.

4. What is the Application of the Electrical Conduit?

Conduit is used in electrical installations to protect, organize, and route wiring systems. From houses to industrial plants, conduits are chosen depending on factors like safety, exposure, and the complexity of wiring. Here are the most common uses for electrical conduit.

Residential Wiring

In residential environments, electrical conduit is used to enclose and protect wiring systems inside walls, ceilings, attics, and basements. It protects against pests, moisture, and inadvertent punctures during home improvements. Conduit also makes it easier to replace or upgrade wires later without tearing down walls.

Commercial Buildings

Conduit is also essential in commercial buildings such as offices, shopping centers, and schools to safely manage lighting, outlets, internet, and HVAC systems. Conduit shields the wires from damage and maintains a clean infrastructure. It also contributes to meeting strict building and safety standards.

Industrial Environments

Conduit protects the wiring from heat, vibration, chemicals, and mechanical impact in industrial environments. Rigid metal electrical conduit is commonly utilized because of its strength and resistance. Such environments require robust and safe wiring solutions for substantial equipment and processes.

Outdoor Installations

For outdoor applications, electrical conduit is common for covering exposed wires from weather, UV, and physical damage. Electrical conduit PVC is standard for landscape lighting, outdoor outlets, and security systems. It protects wires against the elements, whether rain or scorching heat.

Underground Wiring

Conduits protect cables from the effects of soil pressure, moisture, and corrosion experienced in underground electrical systems. It is also quite common with residential and commercial buildings for power lines to be connected to detached structures or lighting systems. It protects the wiring and prolongs the life of the electrical system.

5. How to Choose the Right Electrical Conduit?

Selecting the appropriate electrical conduit is critical to ensuring safety and adherence to electrical standards. It relies on things like the installation environment, the type of wiring, and assurance needs. Here’s what to keep in mind when choosing the best conduit for your project:

Assess the Environment

Identify where the conduit will be installed – indoor, outdoor, underground, or industrial. For wet or corrosive environments, electrical conduit made of PVC or stainless steel is appropriate. RMC or EMT is suitable for areas susceptible to physical damage.

Understand the Wiring Needs

Pay attention to how many and what size wires will be run. Use an electrical conduit size chart to see if the maximum wire fill is within code limits for your conduit.

Choose the Right Material

Select the material based on durability, flexibility, and cost. Metal conduits offer high impact resistance, while plastic ones are lightweight and corrosion-resistant.

Check Local Electrical Codes

Always consult local building codes or a licensed electrician to ensure your conduit type and size meet safety and compliance standards for your location.

Location

For commercial indoor or exposed areas, the EMT or RMC conduits would work best. They are durable and comply with building codes.

Flexibility Needs

Use Flexible Metal Conduit (FMC) if your installation area has tight turns or equipment movement. It flexes readily and accommodates movement. It is ideal for machinery or arrangements that need periodic movement or adjustment.

Corrosion Resistance

In outdoor or corrosive environments, use aluminum or coated conduits. These materials are strong against rusting and chemicals. They’re perfect for coastal regions, industrial factories, or where wires are exposed to extreme environments.

Wire Capacity

To prevent overcrowding, please refer to a conduit size chart for your wire. It means the conduit needs to be able to have wires fit inside without putting them under stress. Additionally, proper sizing facilitates smoother wire-pulling practices for installation and future upgrades.

Code Requirements

Local electrical code regulations always apply. The codes dictate what type and size of conduit you can use in various applications. Compliance helps ensure safety, legality, and passing inspections.

Durability

Use steel or IMC conduits in high-traffic or impact risk areas. They are strong and durable. They protect wiring in warehouses, garages, and industrial settings where durability matters.

Conclusion

Knowing different types of electrical conduit and sizes of electrical conduits is important for safe and effective installation. You must choose the proper conduit type based on your surrounding environment. Make sure to check an electrical conduit size chart or a wire size chart before any wiring project. Conduits made of PVC and metal come with different pros and benefits.

Choosing the right conduit aids in easier system maintenance while improving overall system durability. Be proactive so that you don't have to deal with possible wiring complications later.

Don't forget to share this post!

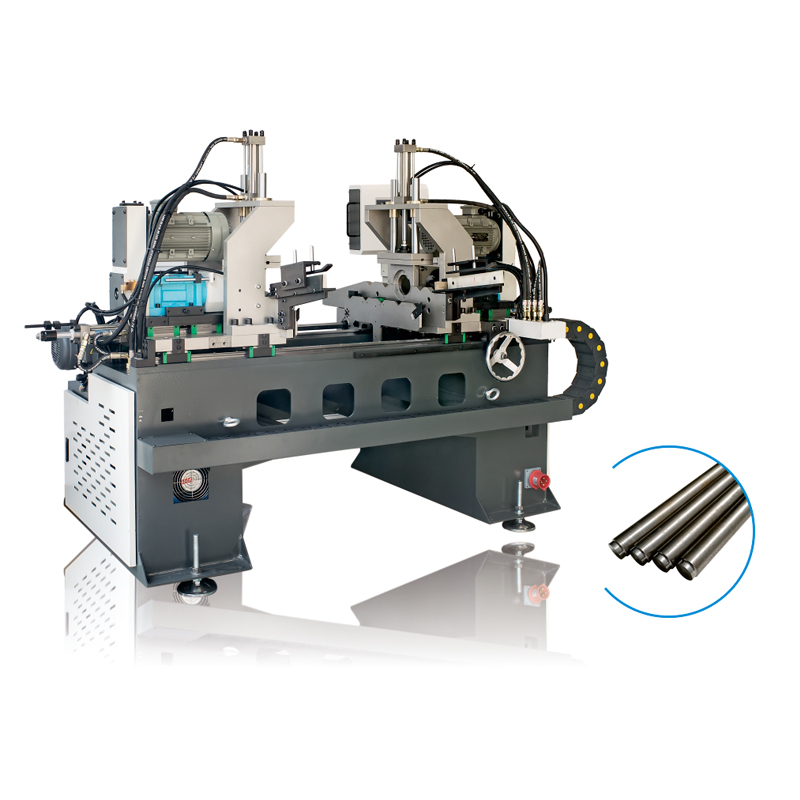

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours