Nominal Pipe Size Chart

Introduction

In plumbing and piping systems, the "Nominal Pipe Size" (NPS) is a critical measurement standard. Another is to be the nominal pipe size that shows dimensions used in different systems to ensure that appropriate sizes are used. The "Nominal Pipe Size" concepts, including outside diameter (OD) and pipe schedules like "pipe schedule 40", play an equally important role in finding the functionality and efficiency of piping systems.

This guide explains how the “Nominal Pipe Size” is different from the outside diameter, why the proper pipe schedule must be chosen, and a deeper analysis of how “Pipe Schedule 40”, along with the other schedules, affects particular applications.

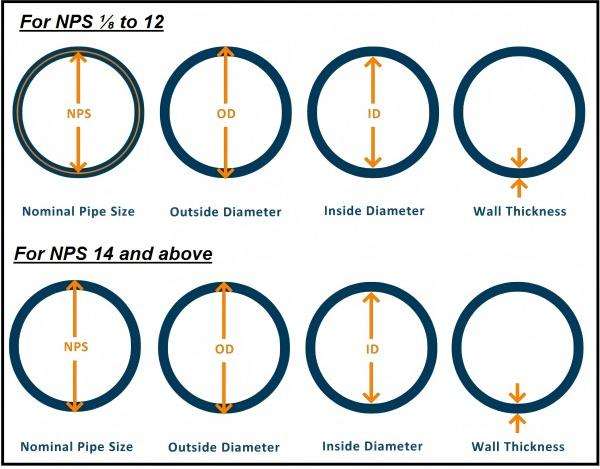

1. Nominal Pipe Size (NPS) and Outside Diameter (OD)

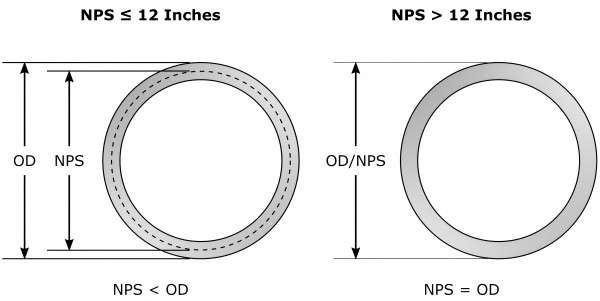

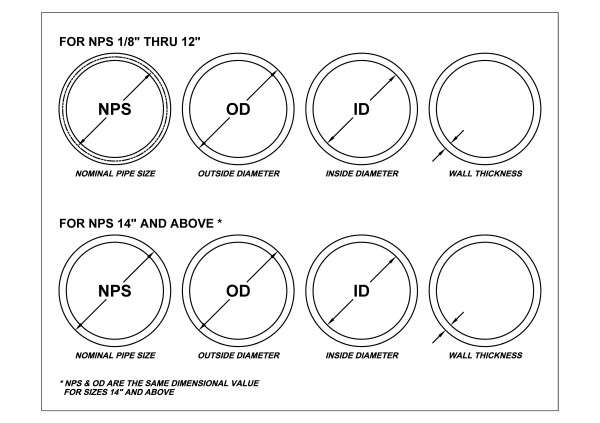

The term nominal pipe size (NPS) is still used today, and it refers only to the approximate diameter of the given pipe in inches. This might be quite surprising given that the name of this term is the “Nominal Pipe Size,” but it actually does not describe the actual outer or even inner diameter of the pipe. In this case, it is a naming convention that denotes an identification system that makes it easy to select pipes. The nominal pipe size and the outer diameter of the pipe are closely related, so appropriate pipe fittings and joining methods may be employed.

For instance, a nominal pipe size of 2 inches refers to a designation of an outside diameter that is slightly above 2 inches. This is because the thickness of the wall of the piping system depends on the pipe schedule; therefore, they create a difference between the two. The ‘Nominal pipe size’ has the advantage at the engineering and construction stage by making pipes of different thicknesses that refer to the same name size.

Outside diameter (OD) is the physical size of the pipe, that is, the distance from the outermost face of the pipe. The relationship between the OD and the “Nominal Pipe Size” is quite important when selecting fitting, flanges, and valves. For instance, where it is written “pipe schedule 40”, the outside diameter is standard, while the wall thickness and, therefore, bore Respiratory Syncytial Virus (RSV) diameter differ from the pipe schedule.

So, the paper has been able to establish that the NPS and outside diameter are correlated factors that guarantee compatibility and operation in piping systems. The “Nominal pipe size”, therefore, becomes a benchmark for engineers, contractors, and manufacturers. Using this benchmark, they can make their selections unanimously, as is made more evident in the case of pipes.

2. The Importance of Using the Correct Pipe Schedule

Recognising the right pipe schedule is as important as recognising the “Nominal Pipe Size”. The pipe schedule 40 provides information about the thickness, the capacity to hold pressure and the weight of the pipe. For example, Pipe Schedule 40 is one of the most used schedules because of the flexibility, which allows the pipes to offer strength and moderate weight.

A pipe schedule essentially refers to the relationship between the pipes' wall thickness and pipes “Nominal Pipe Size”. It conveys the notion for any given NPS, the pipe schedule means a thicker wall and, therefore, a smaller ID of the pipe. This makes the pipe bear and alleviates pressures and mechanical forces, placing it as a desirable pipe for use where a high-pressure fluid conveyance pipe is needed.

In the regions where the “pipe schedule 40” is utilised, thickness seems to be a reasonable compromise between the strength of the material and cost. It is commonly used in conventional building scenarios, institutions, and water supplies like water distribution hose pipes, rainwater supplies, structural supplies and so on. Nevertheless, where operating conditions are more assertive, higher schedules such as schedule 80 may be required in order to offer the necessary pressure.

The correct pipe schedule provides the information necessary to predict whether a piping system will be able to run safely, at the required conditions, and with fixed performance characteristics. There may be a failure in the selection of the material for the pipe schedule and in case of pipe leakages or pipe bursts. Considering the tables of NPS and pipe schedules, engineers can find the suitable pipe type and sizes for the application required.

For instance, in a situation where moderate pressure handling is implemented, there is a product known as Pipe Schedule 40. This means that stainless steel pipes can be found at reasonable prices. It also helps to find compatibility with almost all types of fittings, and thus, many industries are in demand for this product. Therefore, it is also necessary to understand how the NPS relates to the pipe schedule for the right design of the piping systems.

3. Pipe Schedules

Pipe schedules concern the thickness of pipes and are critically important in terms of the strength, weight, and general suitability for the application of a pipe. Pipe Schedule 40 is arguably one of the widely used schedules due to its ability to provide piping solutions at an affordable price. One should have an understanding of several pipe schedules, which would help to ensure that the pipe to be used in the project is sufficient for the intended application.

The flow resistance of a pipe also depends on the pipe schedule number because the thickness of the wall also depends on the pipe schedule number. For instance, “pipe schedule 40” represents moderate wall thickness, which gives the pipe reasonable strength and is also not extremely expensive. They are heavily used in residential, commercial, and industrial sectors for the transportation of fluids, gases, and other materials. Where pressure levels are high and associated strengths are required for a pipe, other types, like schedule 80 or 160, are adopted.

While using the “Nominal Pipe Size”, it is the pipe schedule that defines the inner diameter of the pipe i. For instance, when we have a 4-inch standard pipe diameter referred to as the “Nominal Pipe Size/,” it has a different inside diameter compared to the same pipe but with “pipe schedule 80.” This variation allows the engineer to categorise pipes in terms of size and schedule needs of the particular application.

Pipe schedules and materials – ‘pipe schedule 40’ in particular – are broadly compatible and available in a number of industries. In plumbing and HVAC, oil and gas pipelines or any pipe installation, the flexibility to decide on a pipe with the right thickness gives reliability in the working conditions that come with it.

Hence, pipe schedules may well be understood as some of the simplest or fundamental properties of piping, which describe the pipe’s potential for strength, weight, and load-bearing capacity. The fact that there is such a thing as “pipe schedule 40” demonstrates that its applicability is too applicable, generating an increased demand. By engineering and construction, pipeline schedules respond to the ability to represent networks that are functional and sustainable.

| Pipe Size |

OD | ID | Schedules | Wall | Est Wt LBS per Ft |

| 1/8” | .405 | .307 | 10, 10S | .049 | .1863 |

| .269 | 40, STD, 40S | .068 | .2447 | ||

| .215 | 80, XS, 80S | .095 | .3145 | ||

| 1/4” | .540 | .410 | 10, 10S | .065 | .3297 |

| .364 | 40, STD, 40S | .088 | .4248 | ||

| .302 | 80, XS, 80S | .119 | .5351 | ||

| 3/8” | .675 | .545 | 10, 10S | .065 | .4235 |

| .493 | 40, STD, 40S | .091 | .5676 | ||

| .423 | 80, XS, 80S | .126 | .7388 | ||

| 1/2” | .840 | .674 | 10, 10S | .083 | .6710 |

| .622 | 40, STD, 40S | .109 | .8510 | ||

| .546 | 80, XS, 80S | .147 | 1.088 | ||

| .466 | 160 | .187 | 1.304 | ||

| .252 | XX | .294 | 1.714 | ||

| 3/4” | 1.050 | .884 | 10, 10S | .083 | .8572 |

| .824 | 40, STD, 40S | .113 | 1.131 | ||

| .742 | 80, XS, 80S | .154 | 1.474 | ||

| .614 | 160 | .218 | 1.937 | ||

| .434 | XX | .308 | 2.441 | ||

| 1” | 1.315 | 1.097 | 10, 10S | .109 | 1.404 |

| 1.049 | 40, STD, 40S | .133 | 1.679 | ||

| .957 | 80, XS, 80S | .179 | 2.172 | ||

| .815 | 160 | .250 | 2.844 | ||

| .599 | XX | .358 | 3.659 | ||

| 1 1/4” | 1.660 | 1.442 | 10, 10S | .109 | 1.806 |

| 1.380 | 40, STD, 40S | .140 | 2.273 | ||

| 1.278 | 80, XS, 80S | .191 | 2.997 | ||

| 1.160 | 160 | .250 | 3.765 | ||

| .896 | XX | .382 | 5.214 | ||

| 1 1/2” | 1.900 | 1.682 | 10, 10S | .109 | 2.085 |

| 1.610 | 40, STD, 40S | .145 | 2.718 | ||

| 1.500 | 80, XS, 80S | .200 | 3.631 | ||

| 1.337 | 160 | .281 | 4.859 | ||

| 1.100 | XX | .400 | 6.408 | ||

| 2” | 2.375 | 2.157 | 10, 10S | .109 | 2.638 |

| 2.067 | 40, STD, 40S | .154 | 3.853 | ||

| 1.939 | 80, XS, 80S | .218 | 5.022 | ||

| 1.687 | 160 | .344 | 7.462 | ||

| 1.503 | XX | .436 | 9.029 | ||

| 2 1/2” | 2.875 | 2.635 | 10, 10S | .120 | 3.531 |

| 2.469 | 40, STD, 40S | .203 | 5.793 | ||

| 2.323 | 80, XS, 80S | .276 | 7.651 | ||

| 2.125 | 160 | .375 | 10.01 | ||

| 1.771 | XX | .552 | 13.70 | ||

| 3” | 3.500 | 3.260 | 10, 10S | .120 | 4.332 |

| 3.068 | 40, STD, 40S | .216 | 7.576 | ||

| 2.900 | 80, XS, 80S | .300 | 10.25 | ||

| 2.624 | 160 | .438 | 14.32 | ||

| 2.300 | XX | .600 | 18.58 | ||

| 3 1/2” | 4.000 | 3.760 | 10, 10S | .120 | 4.937 |

| 3.548 | 40, STD, 40S | .226 | 9.109 | ||

| 3.364 | 80, XS, 80S | .318 | 12.51 | ||

| 2.728 | XX | .636 | 22.85 | ||

| 4” | 4.500 | 4.260 | 10, 10S | .120 | 5.613 |

| 4.026 | 40, STD, 40S | .237 | 10.790 | ||

| 3.826 | 80, XS, 80S | .337 | 14.98 | ||

| 3.624 | 120 | .438 | 19 | ||

| 3.438 | 160 | .531 | 22.51 | ||

| 3.152 | XX | .674 | 27.54 | ||

| 4 1/2” | 5.000 | 4.506 | STD, 40S | .247 | 12.54 |

| 4.290 | XS, 80S | .355 | 17.61 | ||

| 5” | 5.563 | 5.295 | 10, 10S | .134 | 7.770 |

| 5.047 | 40, STD, 40S | .258 | 14.62 | ||

| 4.813 | 80, XS, 80S | .375 | 20.78 | ||

| 4.563 | 120 | .500 | 27.04 | ||

| 4.313 | 160 | .625 | 32.96 | ||

| 4.063 | XX | .750 | 38.55 | ||

| 6” | 6.625 | 6.357 | 10, 10S | .134 | 9.290 |

| 6.065 | 40, STD, 40S | .280 | 18.97 | ||

| 5.761 | 80, XS, 80S | .432 | 28.57 | ||

| 5.501 | 120 | .562 | 35.39 | ||

| 5.189 | 160 | .719 | 43.35 | ||

| 4.897 | XX | .864 | 53.16 | ||

| 8” | 8.625 | 8.329 | 10, 10S | .148 | 13.40 |

| 8.125 | 20 | .250 | 22.36 | ||

| 8.071 | 30 | .277 | 24.70 | ||

| 7.981 | 40, STD, 40S | .322 | 28.55 | ||

| 7.813 | 60 | .406 | 35.64 | ||

| 7.625 | 80, XS, 80S | .500 | 43.39 | ||

| 7.439 | 100 | .594 | 50.95 | ||

| 7.189 | 120 | .719 | 61.71 | ||

| 7.001 | 140 | .812 | 67.76 | ||

| 6.813 | 160 | .906 | 74.79 | ||

| 6.875 | XX | .875 | 72.42 | ||

| 10” | 10.750 | 10.420 | 10, 10S | .165 | 18.65 |

| 10.250 | 20 | .250 | 28.04 | ||

| 10.136 | 30 | .307 | 34.24 | ||

| 10.020 | 40, STD, 40S | .365 | 40.48 | ||

| 9.750 | 60, XS, 80S | .500 | 54.74 | ||

| 9.564 | 80 | .594 | 64.43 | ||

| 9.314 | 100 | .719 | 77.03 | ||

| 9.064 | 120 | .844 | 82.29 | ||

| 8.750 | 140, XX | 1.000 | 104.1 | ||

| 8.500 | 160 | 1.125 | 115.6 | ||

| 12” | 12.750 | 12.390 | 10, 10S | .180 | 24.16 |

| 12.250 | 20 | .250 | 33.38 | ||

| 12.090 | 30 | .330 | 43.77 | ||

| 12.000 | STD, 40S | .375 | 49.56 | ||

| 11.938 | 40 | .406 | 53.52 | ||

| 11.750 | XS, 80S | .500 | 65.42 | ||

| 11.626 | 60 | .562 | 73.15 | ||

| 11.376 | 80 | .688 | 88.63 | ||

| 11.064 | 100 | .844 | 107.9 | ||

| 10.750 | 120, XX | 1.000 | 125.5 | ||

| 10.500 | 140 | 1.125 | 136.7 | ||

| 10.126 | 160 | 1.312 | 150.3 | ||

| 14” | 14.000 | 13.624 | 10S | .188 | 27.73 |

| 13.500 | 10 | .250 | 36.71 | ||

| 13.375 | 20 | .312 | 45.61 | ||

| 13.250 | 30, STD, 40S | .375 | 54.57 | ||

| 13.124 | 40 | .438 | 63.44 | ||

| 13.000 | XS, 80S | .500 | 72.09 | ||

| 12.814 | 60 | .594 | 85.05 | ||

| 12.500 | 80 | .750 | 106.1 | ||

| 12.124 | 100 | .938 | 130.9 | ||

| 11.814 | 120 | 1.09 | 150.8 | ||

| 11.500 | 140 | 1.250 | 170.2 | ||

| 11.188 | 160 | 1.406 | 189.1 | ||

| 16” | 16.000 | 15.624 | 10S | .188 | 31.75 |

| 15.500 | 10 | .250 | 42.05 | ||

| 15.375 | 20 | .312 | 52.27 | ||

| 15.250 | 30, STD, 40S | .375 | 62.58 | ||

| 15.000 | 40, XS, 80S | .500 | 82.77 | ||

| 14.688 | 60 | .656 | 107.5 | ||

| 14.314 | 80 | .844 | 136.6 | ||

| 13.938 | 100 | 1.031 | 164.8 | ||

| 13.564 | 120 | 1.22 | 192.4 | ||

| 13.124 | 140 | 1.438 | 223.6 | ||

| 12.814 | 160 | 1.594 | 245.3 | ||

| 18” | 18.000 | 17.624 | 10S | .188 | 35.76 |

| 17.500 | 10 | .250 | 47.99 | ||

| 17.375 | 20 | .312 | 58.94 | ||

| 17.250 | STD, 40S | .375 | 70.59 | ||

| 17.124 | 30 | .438 | 82.15 | ||

| 17.000 | XS, 80S | .500 | 93.45 | ||

| 16.876 | 40 | .562 | 104.7 | ||

| 16.500 | 60 | .750 | 138.2 | ||

| 16.126 | 80 | .938 | 170.9 | ||

| 15.688 | 100 | 1.156 | 208.00 | ||

| 15.250 | 120 | 1.38 | 244.10 | ||

| 14.876 | 140 | 1.562 | 274.20 | ||

| 14.438 | 160 | 1.781 | 308.5 | ||

| 20” | 20.000 | 19.564 | 10S | .218 | 48.05 |

| 19.500 | 10 | .250 | 52.73 | ||

| 19.250 | 20, STD, 40S | .375 | 78.6 | ||

| 19.000 | 30, XS, 80S | .500 | 104.10 | ||

| 18.812 | 40 | .594 | 123.10 | ||

| 18.376 | 60 | .812 | 155.40 | ||

| 17.938 | 80 | 1.031 | 208.90 | ||

| 17.438 | 100 | 1.281 | 256.10 | ||

| 17.000 | 120 | 1.500 | 296.40 | ||

| 16.500 | 140 | 1.750 | 341.10 | ||

| 16.064 | 160 | 1.969 | 379.20 | ||

| 24” | 24.000 | 23.500 | 10, 10S | .250 | 63.41 |

| 23.250 | 20, STD, 40S | .375 | 96.42 | ||

| 23.000 | XS, 80S | .500 | 125.50 | ||

| 22.876 | 30 | .562 | 140.70 | ||

| 22.626 | 40 | .688 | 171.30 | ||

| 22.064 | 60 | .969 | 238.40 | ||

| 21.564 | 80 | 1.219 | 296.80 | ||

| 20.938 | 100 | 1.531 | 357.40 | ||

| 20.376 | 120 | 1.812 | 429.40 | ||

| 19.876 | 140 | 2.062 | 483.10 | ||

| 19.314 | 160 | 2.344 | 542.10 | ||

| 30” | 30.000 | 29.376 | 10, 10S | .312 | 98.93 |

| 29.250 | STD, 40S | .375 | 118.65 | ||

| 29.000 | 20, XS, 80S | .500 | 157.53 | ||

| 28.750 | 30 | .625 | 196.06 | ||

| 36” | 36.000 | 35.376 | 10 | .312 | 118.92 |

| 35.250 | STD, 40S | .375 | 142.68 | ||

| 35.000 | XS, 80S | .500 | 189.57 | ||

| 34.750 | 30 | .625 | 235.13 | ||

| 48” | 48.000 | 47.250 | STD, 40S | .375 | 190.74 |

| 47.000 | XS, 80S | .500 | 253.65 |

Conclusion

The Nominal Pipe Size is a crucial standard by which the pipes can be easily selected and then matched with the other systems. This way, engineers are able to make sure that its components fit perfectly together by making a comparison between the “Nominal Pipe Size” and the outside diameter of pipes. It’s also crucial to understand that specifying the right pipe schedule, for instance, “pipe schedule 40, “ is crucial when constructing pipelines. It bypasses pressures-built, weight-carrying and other factors that facilitate the pipe operation within specific environmental conditions.

Pipe schedules present the improvement of the chance to adapt a system to perform separate tasks or operate at high pressures. Pipe Schedule 40 has gradually become a standard schedule due to its proven ability to combine cost, strength, and market accessibility.

The complexity of defining the “Nominal Pipe Size” and pipe schedules enables engineers and contractors to build proper piping systems that will appropriately meet safety, efficiency, and reliability criteria. It also refers to use in residential construction and constriction and also in industrial facilities where water pipelines are important for performance and durability.

Our Armpre Machinery can provide customized Pipe Processing Machine and electric tapping machine to meet your Nominal Pipe Size products requirement.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours