Pipe Fittings Size Chart

Introduction

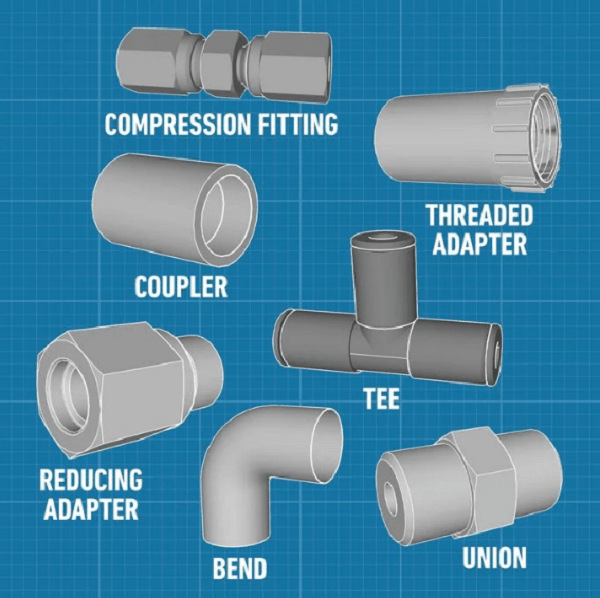

Pipe fittings are the unsung heroes of pipelines and plumbing. They connect pipes, redirect flow, and distribute liquid, gas, or even solids. Without them, most systems that we use today-whether in homes, industries, or transportation-would not work.

PVC pipe fittings and specialized pipe fitting types like couplings, valves, and others emphasize efficiency, safety, and durability in every system component. They are component parts that every aspiring plumbing professional or DIYer needs to know for any piping project.

1.What Is a Pipe Fitting?

Pipe fitting refers to the components designed to connect, switch, or control the flow in a piping system. Such fittings ensure proper flow and distribution of materials without leakage and loss of efficiency. Between home plumbing and an intricate industrial installation, pipe fittings are just about everything that connects and works seamlessly.

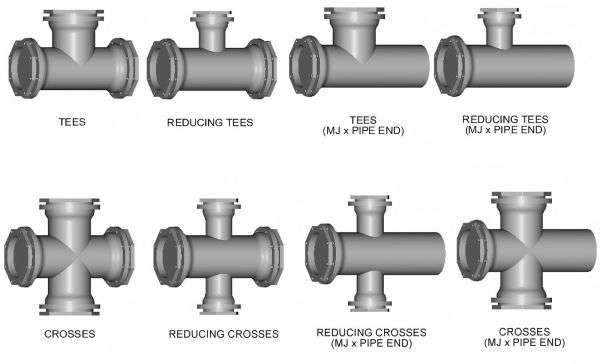

With so many different types of pipe fittings, the applications are really limitless. Take PVC pipe fittings; as the name suggests, they are commonly used in legwork projects such as irrigation. Steel fittings handle the pressure. They cater to specific needs, adapt the pipeline to the layout and conditions, and fall under components such as reducers, elbows, adapters, and couplings.

The right pipe fittings and fitting length enhance durability, improve flow efficiency, and ensure the system can handle different pressures and temperatures. Whether you're using tees to connect multiple lines or nipples to extend pipes, choosing the correct fitting is a must for any project.

2.What Is the Pipe Fitting Size Chart?

A pipe fitting size chart is also a very important tool, especially for professionals and hobbyists. This provides exact measurements for different types of fittings to choose which size will apply to a piping system. With an incorrect size, he runs the risk of having inefficiencies, leaks, and a total failure of the system. For instance, while working with tees or crosses, the size chart helps determine the exact dimensions needed to connect pipes accurately.

Using a size chart also saves time and prevents costly mistakes. Instead of guessing or trying multiple fittings, you can refer to the chart and make the right choice instantly. For a comprehensive guide, companies like Aeroflow Performance offer detailed and reliable size charts for various industries.

| Nominal Size | Thread per inch | Major Diameter | PitchDiameter | Minor Diameter |

| #1 | 64 | 0.073 | 0.063 | 0.056 |

| #2 | 56 | 0.086 | 0.074 | 0.067 |

| #3 | 48 | 0.099 | 0.086 | 0.076 |

| #4 | 40 | 0.112 | 0.096 | 0.085 |

| #5 | 40 | 0.125 | 0.109 | 0.098 |

| #6 | 32 | 0.138 | 0.118 | 0.104 |

| #8 | 32 | 0.164 | 0.144 | 0.130 |

| #10 | 24 | 0.190 | 0.163 | 0.145 |

| #12 | 24 | 0.216 | 0.189 | 0.171 |

| 1/4 | 20 | 0.250 | 0.218 | 0.196 |

| 5/16 | 18 | 0.313 | 0.276 | 0.252 |

| 3/8 | 16 | 0.375 | 0.334 | 0.307 |

| 7/16 | 14 | 0.438 | 0.391 | 0.360 |

| 1/2 | 13 | 0.500 | 0.450 | 0.417 |

| 9/16 | 12 | 0.563 | 0.508 | 0.472 |

| 5/8 | 11 | 0.625 | 0.566 | 0.527 |

| 3/4 | 10 | 0.750 | 0.685 | 0.642 |

| 7/8 | 9 | 0.875 | 0.803 | 0.755 |

| 1 | 8 | 1.000 | 0.919 | 0.865 |

| 11/8 | 7 | 1.125 | 1.032 | 0.941 |

| 11/4 | 7 | 1.250 | 1.157 | 1.095 |

| 13/8 | 6 | 1.375 | 1.267 | 1.195 |

| 11/2 | 6 | 1.500 | 1.392 | 1.320 |

| 13/4 | 5 | 1.750 | 1.620 | 1.534 |

| 2 | 41/2 | 2.000 | 1.856 | 1.759 |

| 21/4 | 41/2 | 2.250 | 2.106 | 2.009 |

| 21/2 | 4 | 2.500 | 2.338 | 2.229 |

| 23/4 | 4 | 2.750 | 2.588 | 2.479 |

| 3 | 4 | 3.000 | 2.838 | 2.729 |

| 31/4 | 4 | 3.250 | 3.088 | 2.979 |

| 31/2 | 4 | 3.500 | 3.338 | 3.229 |

| 33/4 | 4 | 3.750 | 3.588 | 3.479 |

| 4 | 4 | 4.000 | 3.838 | 3.729 |

3.What Materials are Used for Pipe Fittings?

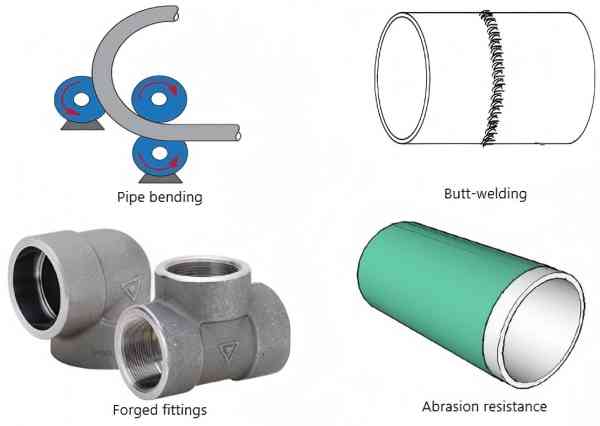

Different types of materials are used for pipe fitting and can make all the difference in performance and durability. These are all selected based on how strong a certain material is, how it can resist corrosion, and in what environments they can be used. Here are some commonly used materials:

1.PVC Pipe Fittings: As widely known, aluminum is a relatively light metal, resistant to corrosion, and relatively cheap. These are most suitable for water supply systems such as plumbing and drainage and for irrigation.

2.Steel and Stainless Steel: These materials are tough, heat- and pressure-resistant, and are majorly applied in industries and under high pressure.

3. Copper Fitting: Chosen more often for hot and cold water systems since this material has high thermal conductivity and has no tendency for bacterial formation.

4.Brass: Has good corrosion features and is commonly used where there is a need for a strong and durable fitting.

The choice of the material is relative to the working parameters of the project. For instance, reducers made of steel are great for heavy-duty industrial pipelines, while PVC pipe fittings are perfect for lightweight, non-corrosive environments. Components like valves, adapters, and elbows are also material-specific to ensure they perform optimally under different conditions.

4.Applications of Pipe Fittings

Pipe fittings are used in virtually every industry that involves pipelines. Here are some key applications:

1.Automotive: These fittings are applied in the likes of fuel delivery systems, braking systems, hydraulic systems, etc.

2.Electronics: Heating and cooling systems used for high-performance electronics such as CPU and GPU depend on accurate fittings for controlling the flow of the coolant.

3.Manufacturing: Pipelines in factories transport liquids, gases, and even fine powders, requiring reliable fittings like crosses, valves, and couplings.

The versatility of pipe fitting types makes them indispensable in these sectors. Products like tees allow for the distribution of materials in multiple directions, while unions enable easy disconnection for maintenance. Proper fittings enhance system functionality, operational interruptions, and the system’s ability to last long.

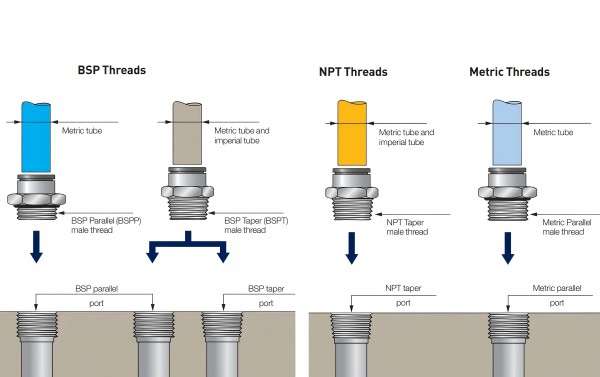

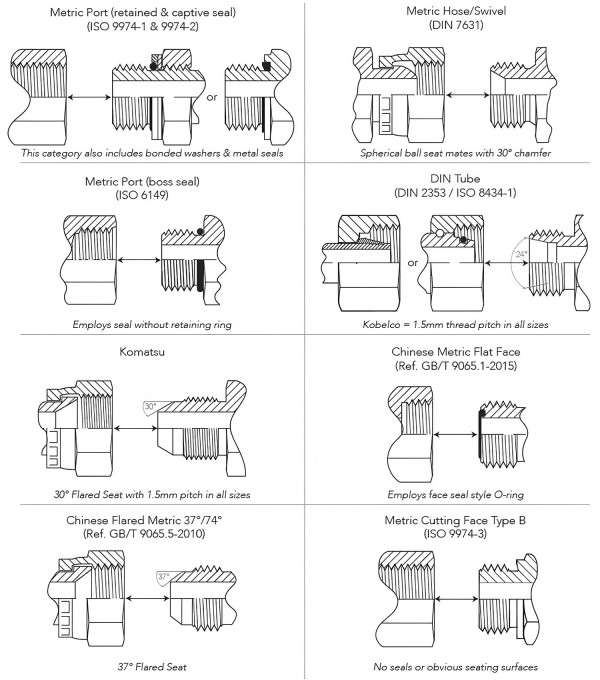

5.Pipe Fitting Standards

Standards are very important in every aspect covering piping systems in terms of compatibility, safety, and quality, evidencing reliability. When working with pipe fitting types, it’s essential to understand these common standards:

- NPT (National Pipe Tapered): Commonly used in North America for creating tight, pressure-resistant connections.

- NPTF (Dryseal National Pipe Tapered): Designed for leak-proof connections without additional sealants.

- BSPT/BSPP (British Standard Pipe Taper/Parallel): Popular in Europe and Asia for versatile applications.

- SAE (Society of Automotive Engineers): Mainly, it is employed in automotive systems, specifically in the products that have an application in the passage of fluids.

- UN and UNF (Unified National and Unified National Fine): General-purpose threads for various industries.

Understanding these standards ensures that fittings like adapters, nipples, and couplings work seamlessly together, regardless of the application. For detailed information, check out resources like Aeroflow Performance , where you’ll find expert guidance on standards and compatibility.

6.How to Choose the Right Pipe Fitting

Selection of the right pipe fitting requires much more than just picking the right size. Here are some tips to guide you:

1.Cutting Metric Thread: This technique is ideal for achieving precision when working with components like tees, reducers, and unions.

2.Extruding Thread: A robust option for creating threads on durable materials like brass or steel, ensuring a secure and long-lasting connection.

Consider factors like pressure, temperature, and environmental conditions when choosing fittings. For example, elbows are perfect for sharp turns in pipelines, while crosses are better suited for splitting flow into multiple directions. Referring to a size chart ensures you don’t end up with mismatched components that compromise the system's efficiency.

Conclusion

From understanding pipe fitting types to selecting the right materials like PVC pipe fittings or stainless steel, choosing the correct fitting is vital for any piping project. Whether you need reducers, adapters, tees, or valves, making informed decisions based on size, material, and application ensures a reliable and efficient system.

For detailed guidance and accurate pipe size tables, please visit Armpro Machine. Our range of accessories and expert advice ensures that you will find the perfect solution that meets your needs.

Related Reading

1、What is an Fitting?

The full name of AN is Army Navy, and AN Fitting is a set of connectors derived from strict military standards. This set of connectors has become the preferred choice for many high-precision industries due to its extremely stable and reliable quality.

2、What is the PU connector size chart?

Here is the PU connector size chart. I hope it can help you.

| MODEL | SIZE | MODEL | SIZE | MODEL | SIZE |

| M5-4 | 4xM5 | M5-6 | 6xM5 | M6-8 | 8-M6 |

| M6-4 | 4xM6 | M6-6 | 6xM6 | 08-01 | 8×1/8" |

| 04-01 | 4x1/8" | 06-01 | 6×1/8" | 08-02 | 8×1/4" |

| 04-02 | 4x1/4" | 06-02 | 6×1/4" | 08-03 | 8×3/8" |

| 04-03 | 4×3/8" | 06-03 | 6×3/8" | 08-04 | 8×1/2" |

| 04-04 | 4x1/2" | 06-04 | 6×1/2” | 10-01 | 10×1/8" |

| 12-02 | 12×1/4" | M5-8 | 8-M5 | 10-02 | 10×1/4" |

| 12-03 | 12×3/8" | 16-04 | 16x1/2" | 10-03 | 10×3/8" |

| 12-04 | 12×1/2" | 16-02 | 16×1/4" | 10-04 | 10×1/2" |

| 14-02 | 14×1/4" | 16-03 | 16×3/8" | 12-01 | 12×1/8" |

| 14-03 | 14×3/8" | 14-04 | 14×1/2" |

3、What is the PVC pipe fitting size chart?

Here is the PVC pipe fitting size chart. I hope it can help you.

| PVC pipe fitting size chart | |||||

| Nom.Pipe Size (in) |

0.D. | Average L.D. |

Min. Wall |

Nominal Wt./Ft. |

Maximum W.P.PSI* |

| 1/8 | 0.405 | 0.249 | 0.068 | 0.051 | 810 |

| 1/4 | 0.540 | 0.344 | 0.088 | 0.086 | 780 |

| 3/8 | 0.675 | 0.473 | 0.091 | 0.115 | 620 |

| 1/2 | 0.840 | 0.602 | 0.109 | 0.170 | 600 |

| 3/4 | 1050 | 0.804 | 0.113 | 0.226 | 480 |

| 1 | 1.315 | 1.029 | 0.133 | 0.333 | 450 |

| 1-1/4 | 1.660 | 1.360 | 0.140 | 0.450 | 370 |

| 1-1/2 | 1.900 | 1.590 | 0.145 | 0.537 | 330 |

| 2 | 2.375 | 2.047 | 0.154 | 0.720 | 280 |

| 2-1/2 | 2.875 | 2.445 | 0.203 | 1.136 | 300 |

| 3 | 3.500 | 3.042 | 0.216 | 1.488 | 260 |

| 3-1/2 | 4.000 | 3.521 | 0.226 | 1.789 | 240 |

| 4 | 4.500 | 3.998 | 0.237 | 2.118 | 220 |

| 5 | 5.563 | 5.016 | 0.258 | 2.874 | 190 |

| 6 | 6.625 | 6.031 | 0.280 | 3.733 | 180 |

| 8 | 8.625 | 7.942 | 0.322 | 5.619 | 160 |

| 10 | 10.750 | 9.976 | 0.365 | 7.966 | 140 |

| 12 | 12.750 | 11.889 | 0.406 | 10.534 | 130 |

| 14 | 14.000 | 13.073 | 0.437 | 12.462 | 130 |

| 16 | 16.000 | 14.940 | 0.500 | 16.286 | 130 |

| 18 | 18.000 | 16.809 | 0.562 | 20.587 | 130 |

| 20 | 20.000 | 18.743 | 0.593 | 24.183 | 120 |

| 24 | 24.000 | 22.544 | 0.687 | 33.652 | 120 |

4、What is the plumbing fitting chart?

Here is the plumbing fitting chart. I hope it can help you.

| Nom.Pipe Size (in) |

0.D. | Average L.D. |

Min. Wall |

Nominal Wt./Ft. |

Maximum W.P.PSI* |

| 1/8 | 0.405 | 0.249 | 0.068 | 0.051 | 810 |

| 1/4 | 0.540 | 0.344 | 0.088 | 0.086 | 780 |

| 3/8 | 0.675 | 0.473 | 0.091 | 0.115 | 620 |

| 1/2 | 0.840 | 0.602 | 0.109 | 0.170 | 600 |

| 3/4 | 1050 | 0.804 | 0.113 | 0.226 | 480 |

| 1 | 1.315 | 1.029 | 0.133 | 0.333 | 450 |

| 1-1/4 | 1.660 | 1.360 | 0.140 | 0.450 | 370 |

| 1-1/2 | 1.900 | 1.590 | 0.145 | 0.537 | 330 |

| 2 | 2.375 | 2.047 | 0.154 | 0.720 | 280 |

| 2-1/2 | 2.875 | 2.445 | 0.203 | 1.136 | 300 |

| 3 | 3.500 | 3.042 | 0.216 | 1.488 | 260 |

| 3-1/2 | 4.000 | 3.521 | 0.226 | 1.789 | 240 |

| 4 | 4.500 | 3.998 | 0.237 | 2.118 | 220 |

| 5 | 5.563 | 5.016 | 0.258 | 2.874 | 190 |

| 6 | 6.625 | 6.031 | 0.280 | 3.733 | 180 |

| 8 | 8.625 | 7.942 | 0.322 | 5.619 | 160 |

| 10 | 10.750 | 9.976 | 0.365 | 7.966 | 140 |

| 12 | 12.750 | 11.889 | 0.406 | 10.534 | 130 |

| 14 | 14.000 | 13.073 | 0.437 | 12.462 | 130 |

| 16 | 16.000 | 14.940 | 0.500 | 16.286 | 130 |

| 18 | 18.000 | 16.809 | 0.562 | 20.587 | 130 |

| 20 | 20.000 | 18.743 | 0.593 | 24.183 | 120 |

| 24 | 24.000 | 22.544 | 0.687 | 33.652 | 120 |

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours