Pipe Nipple Size Chart

Introduction

When it comes to plumbing or industrial pipelines, even some electrical setups, pipe nipples are essential parts. Once you know the different types of sizes, materials, and applications, you're able to make the most appropriate decision.

1.What is the Pipe Nipple?

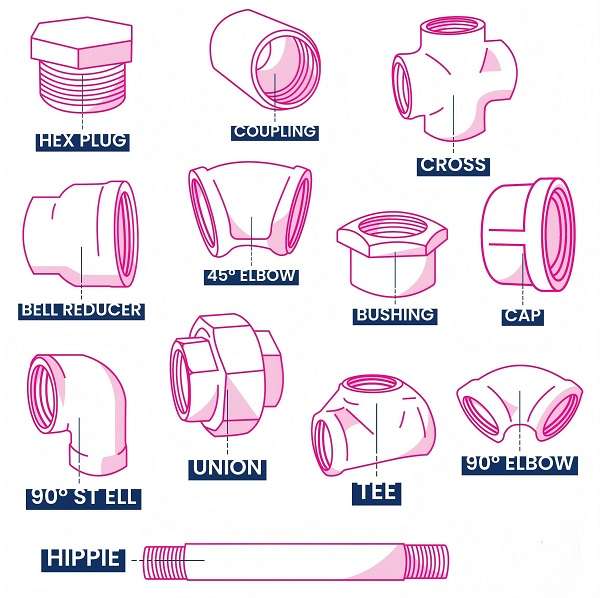

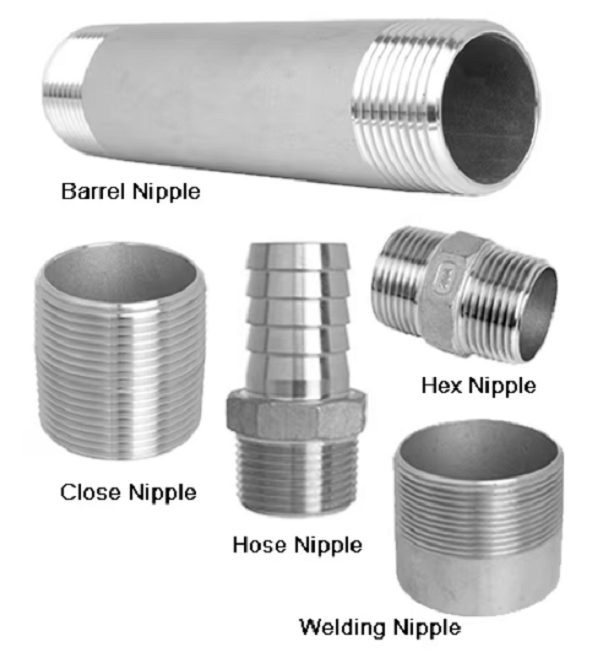

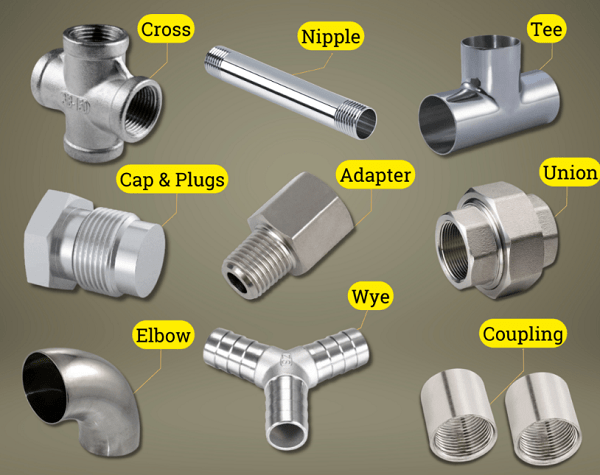

A pipe nipple is a short pipe with threads on both sides. This is what makes it capable of joining two other pipes or fittings together. It's very important in plumbing systems and is usually called a nipple coupling, but no matter what it's named, it performs the same job: joining pipes safely and efficiently.

The pipe nipple is most commonly used for making a simple, straight connection. Depending on its application, it can come in different lengths and materials. A union joint is often used for this type of connection; however, it has a different meaning, as it refers to a connector that can be unscrewed to separate pipes.

As for coupling pipe fitting, it refers to any fitting joining these two pipes, and the short insert pipe form of coupling fitting is known as pipe nipple, which is just a narrower definition of coupling.

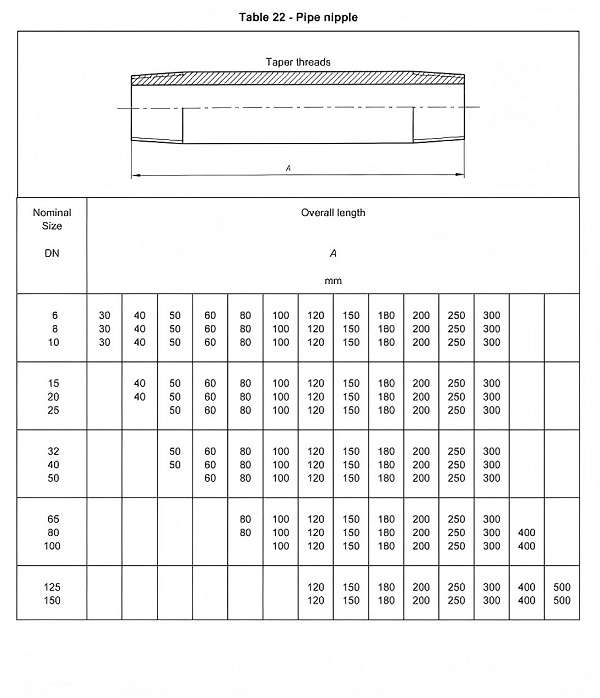

2.What is the Pipe Nipple Size Chart?

This pipe nipple size chart directs what size of nipple you need for your piping system. Pipe nipples vary in size, so it becomes important to choose the correct size for proper sealing and leak-proof connection. Sizes are typically defined in nominal pipe size (NPS) or diameter; length also matters when it comes to the selection of pipe nipples.

Pipe nipples, for example, could range from the most common sizes, like 1/8 inch, 1/4 inch, 1/2 inch, 3/4 inch, and 1 inch, up to sizes far larger than these for heavy-duty industrial work. Most common sizes used in plumbing works would normally be between 1/8 inch and 1 inch, with certain other industries requiring larger or smaller sizes.

The pipe nipple varies in length, with some 1 inch long and others being considerably longer for certain applications. The precise length matters because it tells how far it will extend into fittings.

3.What Materials are Used for Pipe Nipples?

Pipe nipples exist in various materials that are good for different conditions and uses. The most common materials are:

- Brass Pipe Nipple: Theyare built for plumbing systems wherein resistance to corrosion happens to be a top priority. They are strong, give a reliable seal, and are, therefore, appropriate for residential applications.

- PVC Pipe Nipple: PVC pipe nipples are lightweight, chemically and corrosion resistant. It is usually used for water systems, especially in places where high moisture exists or chemical resistance is needed.

- Steel Pipe Nipple: Steel pipe nipplesshow strength and durability and are capable of enduring intensive use. Withstanding heavy stress along with internal and external high-pressure resistance places them appropriate for heavy-duty use in industrial pipelines and other stressful situations.

- Stainless Steel Pipe: Stainless steel pipe nipples are inherently rust and corrosion-resistant. They serve in severities where the condition for durability is utmost, such as in chemical processing, food processing, and outdoor installations.

Each material has its benefits, and choosing the right one depends on the conditions and environment where the pipe nipple will be installed.

4.What is the Application of the Pipe Nipple?

Pipe nipples are used in different settings. Here's where you'll typically find them:

- Plumbing: The most common area where pipe nipples are found is plumbing in a residential or commercial building. Such nipples work as connectors for pipe systems that service water supply, waste removal, or other similar functions requiring dependable and leak-free connections.

- Industrial Pipelines: In industrial settings, pipe nipples are used to connect industrial pipelinescarrying either chemical, gas, or liquid. They are strong and durable, so it is very important in these venues where it is expected that the pipe fittings will be under extremely high pressure and subjected to harsh materials.

- Electrical Boxes: Pipenipples electrically connect conduit pipes to electrical boxesor panels in electrical installation. Its purpose is to serve as a bridge between the electrical conduit pipe and the box.

- Kitchen Tap Pipes: When it comes to using pipe nipples, one major area of application is in kitchen plumbing as part of the processes established to connect water pipes to kitchen tap pipes. The work of a pipe nipple in aplumbing system includes making sure that the water flows accordingly to faucets or other fixtures.

Those are a few examples; however, pipe nipples can be found somewhere almost everywhere systems connect pipes. They are very comprehensive and flexible and constitute a good need in most industries.

5.How to Choose the Right Pipe Nipple?

There are a few keys to consider before selecting the best-fit pipe nipple:

- Size: The most important of these is the size of the pipe nipple. You will need the measurements for the diameter of the pipes that you want to connect. Thus, do not forget to check the pipe nipple sizechart to avoid mistakes regarding fit.

- Material: The material of the pipe nippleis also critical. You may also use brass pipe nipples for non-corrosive uses such as water or plumbing You could use a steel pipe nipple or a stainless steel pipe nipple for high industrial heavy-duty applications.

- Length: The length of the pipe nipple should correspond to the space available for installation. You want it neither too long nor too short, as it could influence the easy connection.

- Thread Type: The threads on the pipe nippleshould match those of the connecting pipe or fitting. Make sure to choose the right thread type, whether it's National Pipe Thread or British Standard Pipe.

- Pressure and Temperature Resistance: The nipple must meet the system's pressure and temperature requirements. For high-pressure systems, steel pipe nipples or stainless steel pipe nipples are normally used best.

| Pipe Nipple Size Chart | |||||

| Nom.Pipe Size (in) |

0.D. | Average I.D. |

Min. Wall |

Nominal Wt./Ft. |

Maximum W.P.PSI* |

| 1/8 | 0.405 | 0.249 | 0.068 | 0.051 | 810 |

| 1/4 | 0.540 | 0.344 | 0.088 | 0.086 | 780 |

| 3/8 | 0.675 | 0.473 | 0.091 | 0.115 | 620 |

| 1/2 | 0.840 | 0.602 | 0.109 | 0.170 | 600 |

| 3/4 | 1.050 | 0.804 | 0.113 | 0.226 | 480 |

| 1 | 1.315 | 1.029 | 0.133 | 0.333 | 450 |

| 1-1/4 | 1.660 | 1.360 | 0.140 | 0.450 | 370 |

| 1-1/2 | 1.900 | 1.590 | 0.145 | 0.537 | 330 |

| 2 | 2.375 | 2.047 | 0.154 | 0.720 | 280 |

| 2-1/2 | 2.875 | 2.445 | 0.203 | 1.136 | 300 |

| 3 | 3.500 | 3.042 | 0.216 | 1.488 | 260 |

| 3-1/2 | 4.000 | 3.521 | 0.226 | 1.789 | 240 |

| 4 | 4.500 | 3.998 | 0.237 | 2.118 | 220 |

| 5 | 5.563 | 5.016 | 0.258 | 2.874 | 190 |

| 6 | 6.625 | 6.031 | 0.280 | 3.733 | 180 |

| 8 | 8.625 | 7.942 | 0.322 | 5.619 | 160 |

| 10 | 10.750 | 9.976 | 0.365 | 7.966 | 140 |

| 12 | 12.750 | 11.889 | 0.406 | 10.534 | 130 |

| 14 | 14.000 | 13.073 | 0.437 | 12.462 | 130 |

| 16 | 16.000 | 14.940 | 0.500 | 16.286 | 130 |

| 18 | 18.000 | 16.809 | 0.562 | 20.587 | 130 |

| 20 | 20.000 | 18.743 | 0.593 | 24.183 | 120 |

| 24 | 24.000 | 22.544 | 0.687 | 33.652 | 120 |

Having considered these key factors into consideration, you will be in a position to choose the right pipe nipple for your project.

Conclusion

Pipe Nipples are an important part of pipes and piping systems regardless of the sector, plumbing, industrial, or electrical. With the help of pipe nipple size chart, material, and application,you can get the most from your pipe nipple.

Since pipe nipples are threaded on both ends, they are perfect to join pipes in a quick and secure manner. If you take size, material and other factors into mind, then there is no reason why pipes should not remain connected and functional for a long-term.

For detailed guidance and accurate pipe size tables, please visit Armpro Machine. Our range of accessories and expert advice ensures that you will find the perfect solution that meets your needs.

Don't forget to share this post!

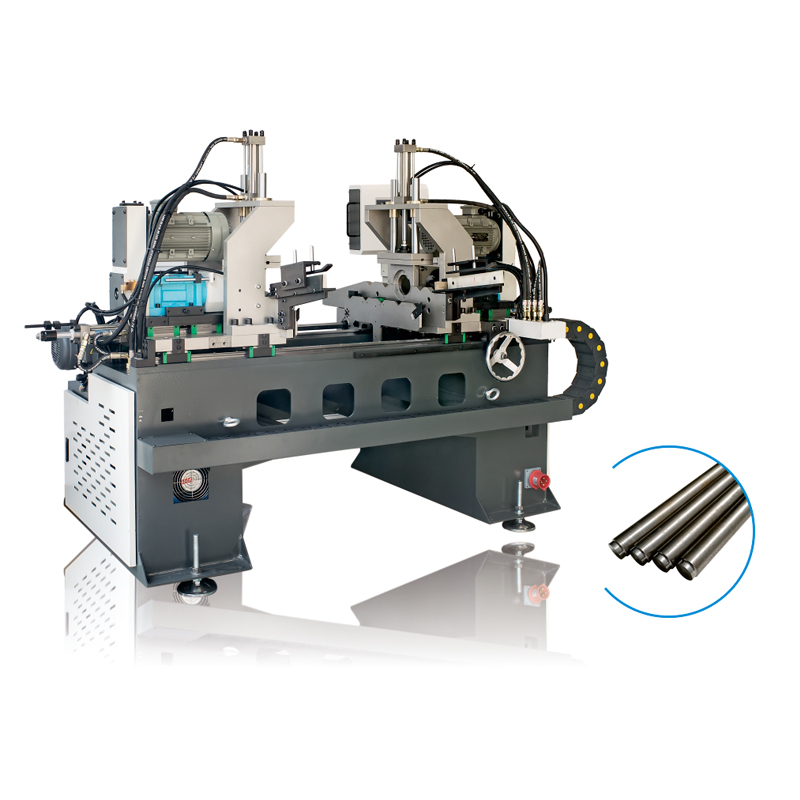

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours