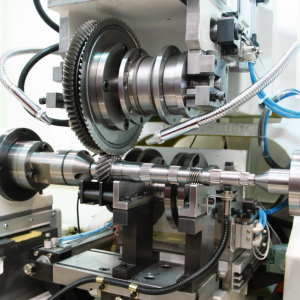

Armpro 9330A CNC Spiral Bevel Gear Chamfering Machine

The 9330A CNC Spiral Bevel Gear Chamfering Machine is a state-of-the-art, five-axis CNC servo-driven system. It features a high-performance Rexroth or SIEMENS 828D CNC system, ensuring precise control and efficiency.

This advanced machine utilizes a linkage interpolation method, where the cutter tool and workpiece spindle operate in tandem via a servo drive motor. This process enables accurate chamfering of tooth profiles on spiral bevel gears.

Key Features:

- Maximum Diameter: Capable of processing spiral bevel gears with a maximum diameter of φ300mm.

- Chamfering Capability: Designed to chamfer the sharp edges of both the big end and the small end of spiral bevel gears.

- Production Versatility: Ideal for both small-batch and large-scale production, accommodating a wide variety of manufacturing needs.

Applications:

The 9330A is particularly suitable for chamfering spiral bevel gears and hypoid gears across various modules, making it a vital tool in machinery manufacturing

Specifications of the 9330A CNC Spiral Bevel Gear Chamfering Machine

1. General Specifications

- Maximum Diameter: 300 mm

- Minimum Diameter: 50 mm

2. Processing Range

- Chamfers sharp edges of both large and small ends of spiral bevel gears.

3. Workpiece Spindle

- Diameter of Spindle Straight Hole: Φ90 mm

- Depth of Spindle Straight Hole: 15 mm

4. Motorized Spindle

- Maximum Diameter of Cutter Holder: Φ16 mm

- Power of Motorized Spindle: 1.1 kW

- Speed of Motorized Spindle: 6000 r/min

5. Drive Spindle Torque

- Horizontal Movement (X1, X2): Servo motors with 8 Nm torque

- Vertical Movement (Y1, Y2): Servo motors with 8 Nm torque

- Workpiece Spindle Indexing (A): Torque motor with 12 Nm

6. Overall Dimensions

- Dimensions (L × W × H): 2300 mm × 1650 mm × 2350 mm

7. Weight

- Approximate Weight: 3000 kg

The 9330A CNC Spiral Bevel Gear Chamfering Machine features a vertical layout and is composed of three main systems: the main machine, pneumatic system, and electrical system.

1. Main Machine Components

The main machine includes the following parts:

- Machine Bed

- Workpiece Headstock

- Left and Right Columns

- Tooth Aligning Mechanism

- Protective Housing

These components work together through relative motion to achieve precise gear chamfering.

2. Pneumatic System

The pneumatic system enhances the machine’s functionality by providing power for:

- Pneumatic Clamping of workpieces

- Pneumatic Tooth Alignment

- Workpiece Fixtures

- Blowing Cleaning of Workpieces

- Manual Cleaning with Air Gun

3. Lubrication System

The lubrication system ensures optimal performance with:

- Grease Lubrication for guideways, screws, and bearings

- Oil Lubrication for the worm gear pair in the workpiece headstock

4. Chip Removal System

This machine is equipped with a manual chip collection box for the efficient removal of iron chips during operation.

5. Electrical System

The main components of the electrical system are housed in a dedicated cabinet. For detailed information, refer to the “Electrical Instructions.” Operators can easily control the machine using the buttons on the operation panel.

6. Axis Configuration

The YHZ9330A features:

- Five Servo Axes:

- A: Rotating indexing axis of the workpiece

- X1, X2: Horizontal movement axes of the cutter spindle

- Y1, Y2: Vertical movement axes of the cutter spindle

- Six Manual Axes:

- W1, W2: Manual offset position axes of the cutter spindle

- Z1, Z2: Manual fine-tuning feed axes of the cutter spindle

- B1, B2: Manual rotation axes of the cutter spindle

Chamfering Work Area

The 9330A CNC spiral bevel gear chamfering machine is designed for efficient chamfering of both the big and small ends of spiral bevel gears. It uses double chamfering cutters for separate processing of the gear edges.

Key Features:

- Pneumatic Tooth Alignment Mechanism: This system accurately positions the gear tooth slots using an air cylinder and induction contacts, ensuring automatic tooth alignment. This feature enhances machining efficiency and guarantees high precision in the final workpiece.

- Pneumatic Clamping Cylinder: The workpiece is securely clamped in place, allowing for stable and reliable chamfering operations.

- Linkage Interpolation: The chamfering tool and workpiece spindle operate in sync through servo drive motors, achieving precise tooth profile chamfering.

Advantages:

- Improved machining accuracy

- Simple structure for easy maintenance

- Convenient disassembly for quick adjustments

By integrating these advanced features, the 9330A machine ensures optimal performance in chamfering spiral bevel gears, making it ideal for both small and large production runs.

Reviews

There are no reviews yet.