Working principle:

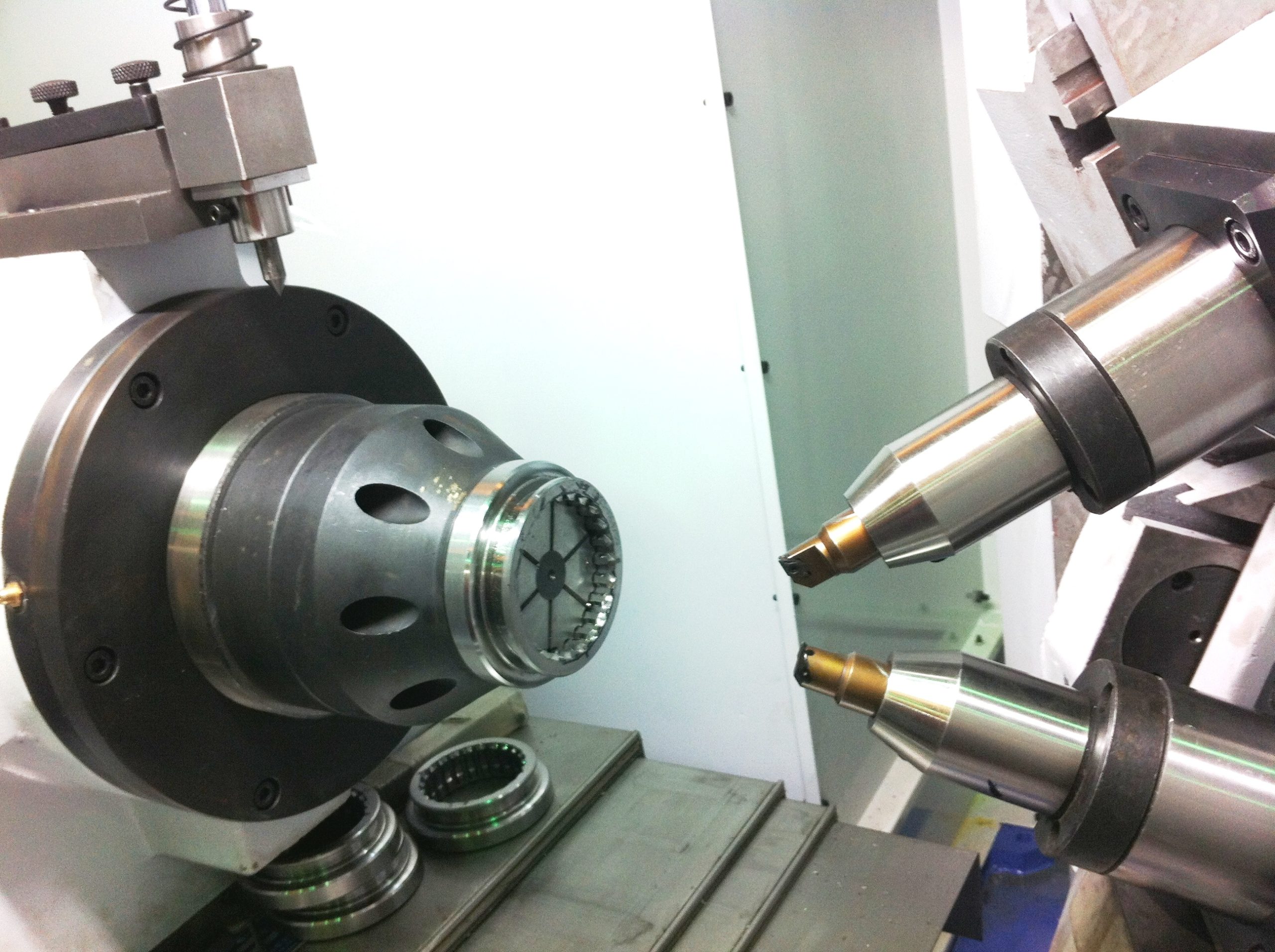

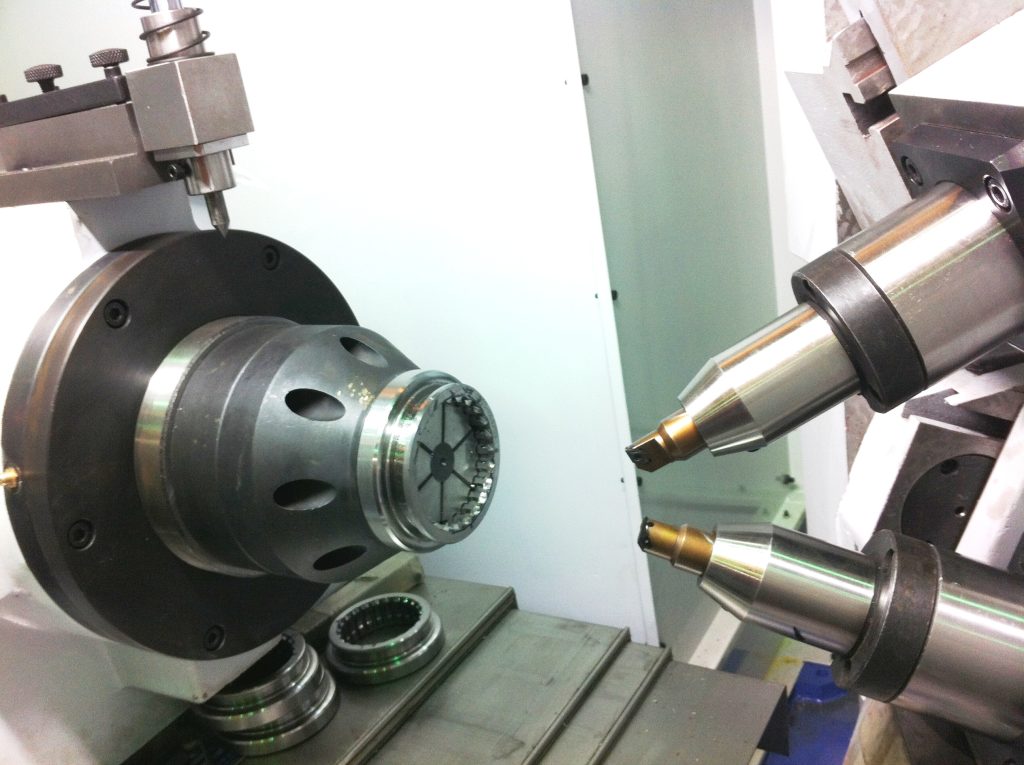

Armpre Machinery developed APK9320X Synchronous Chamfering Machine, the machine adopts the the theory of rotating milling and cycloid principle, the cutter spindle and workpiece spindle are rotated at the same time, one time feed to depth so that complete all teeth processing so the machining efficient can be doubled compared with Index Chamfering machine, The machine can achieve continuous cutting and also indexing cutting.

The machine is characterized by the high-rigidity, high-efficiency, high-accurate, convenient adjustment and operation and stable performance, etc.

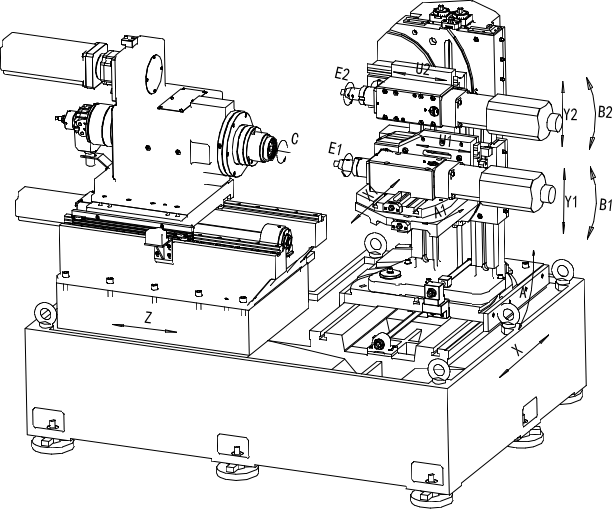

Machine Structure:

The machine adopts SIEMENS 828Dsl CNC control system, it equipped with electric gear box function so that improve the functional performance.

There are Four- axes on the machine: 1. Workpiece rotation; 2. Two cutter spindle rotation; 3. Workpiece headstock feed; The workpiece rotation indexing is driven by belt pulley The cutter spindle adopts high-speed servo motor and connects with cutter spindle directly so that drive the cutter spindle rotation, and avoided transmission clearance and error, the processing accuracy is improved.

The two cutter spindles of the machine are hung on one column, which can move independently in the vertical direction. The whole cutter spindle column can be adjusted in angle and moved longitudinally, and the lower cutter spindle can also be adjusted in angle and moved longitudinally. Linear adjustment adopts rectangle and dovetail guideway, and magnetic grating ruler is used in the linear and angle, which greatly increases the accuracy of the adjustment. With the adjustment calculation software independently developed by our company, it is more convenient and fast to replace the workpiece.

The machine adopts standard chamfering cutter holder & ordinary cutter tip. The alarm diagnosis function of the machine tool can help the user to eliminate the malfunction of machine tool in time and reduce the waiting time of the user to stop the operation, thus ensuring the smooth production.

The machine adopts the non-contact matching tooth of the sensor. The high-precision sensor greatly improves the precision of the tooth, and also avoids the contact tooth, the damage of the workpiece and the wear of the tooth mechanism, and ensures the stability of the tooth precision.

APK9320X Specification

- Max. Pitch Diameter:————————— external gear:30~200 mm

————————— Internal gear:50~200 mm

- Max. Module ——————————————————————— 3mm

- CNC control system ———————————————SIEMENS 828Dsl

- Chamfering angle ————————————– inclined angle:80°~130°

- ————————————-end face angle:0°~15°

- Number of teeth ——————————————————- Above 8 teeth

- Workpiece spindle Swing diameter ——————————- Max.200 mm

- Workpiece spindle Mounting hole diameter —————————- φ90 H7

- Cutter Mounting hole diameter ——————————————- φ20 H7

- Max. Cutter Rotation speed ————————————— Max.6000 rpm

- Main power ——————————————————————— 12 KW

- Weight ————————————————————————– 3500kg

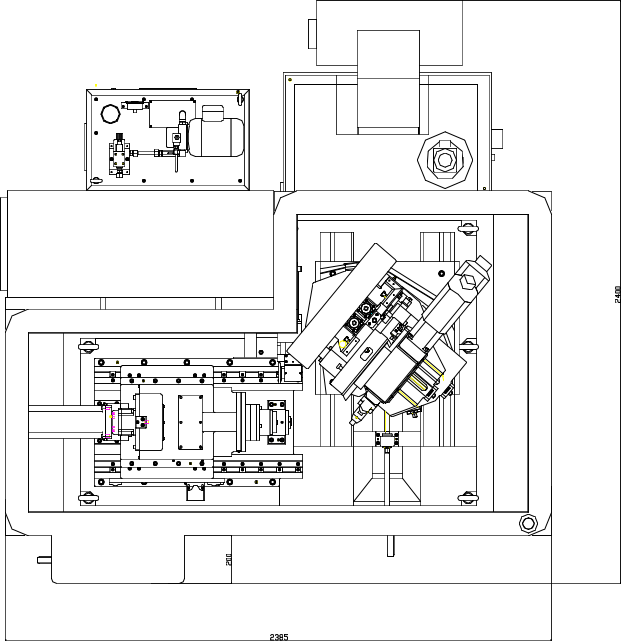

- Overall dimension ————————————- 2385 * 2400*2100 mm

Main configuration

| NO. | Name | Supplier | Remarks |

| 1 | CNC control system | SIEMENS 828Dsl | Four-axis |

| 2 | Main electric component | Schneider | |

| 3 | Linear guideway | TAIWAN | |

| 4 | Ball screw | TAIWAN | |

| 5 | Coupling | LINK | |

| 6 | Main Bearing | NSK | |

| 7 | Sealing elements | Armpro | |

| 8 | Air condition | Armpro | |

| 9 | Precision water-cooling device | Armpro | |

| 10 | Hydraulic unit | HANFOOK | |

| 11 | Pneumatic system | AIRTAC | |

| 12 | Chip conveyor | Tianhai | |

| 13 | Cutter holder | DELI | |

| 14 | Inserts | DELI | |

| 15 | Automatic tooth setting device |

Application

This Synchronous Chamfering machine APK9320X is widely applied to gear chamfering production in engine of automobile, transmission box of car and trucks and synchronizer industry.

Reviews

There are no reviews yet.