ZK36 CNC Tapping Machine

Armpro ZK36 cnc series automatic thread tapping machine enables tapping operation automatically. The automatic mode can effectively control the depth of tapping, without the operation button, automatic control by depth. The integrated input field can be used to switch between automatic and manual mode, which needs to simply set thread depth and speed. The low maintenance and operating costs as well as the pleasant working volume are also an advantage favored by users.

Precision casting frame

Beautiful appearance

Cost effective and low consumption

ZK36 CNC Drilling and Tapping machine machine

Armpro ZK36 cnc series automatic thread tapping machine enables tapping operation automatically. The automatic mode can effectively control the depth of tapping, without the operation button, automatic control by depth. The integrated input field can be used to switch between automatic and manual mode, which needs to simply set thread depth and speed. The low maintenance and operating costs as well as the pleasant working volume are also an advantage favored by users.

APPLICATION FIELD

- Moulds & Dies

- automotive industry

- Auxiliary in CNC machines

- Plate industry

- Mechanization industry

- Aerospace

- Consumer electronics

- Medical industry

- Defense industry

- Oil & gas industry

PRODUCT ADVANTAGES

- Includes quick change chuck for use of taps for through and blind holes

- Tiltable motor unit for tapping at any required angle between 0° and 90°

- Higher accuracy compared to manual tapping, thread is guaranteed right angle (90 °)

- High productivity, significant time savings compared to manual tapping

- Quick-change chuck with integrated safety clutch prevents breakage of the tap drill

- Optionally available magnetic base for direct use on large and heavy workpieces

- Including swivel arm with large radius for easy positioning of the tap drill on the workpiece

- Highly economical due to low investment and maintenance costs

- For tapping in steel, stainless steel, aluminum and non-ferrous metals

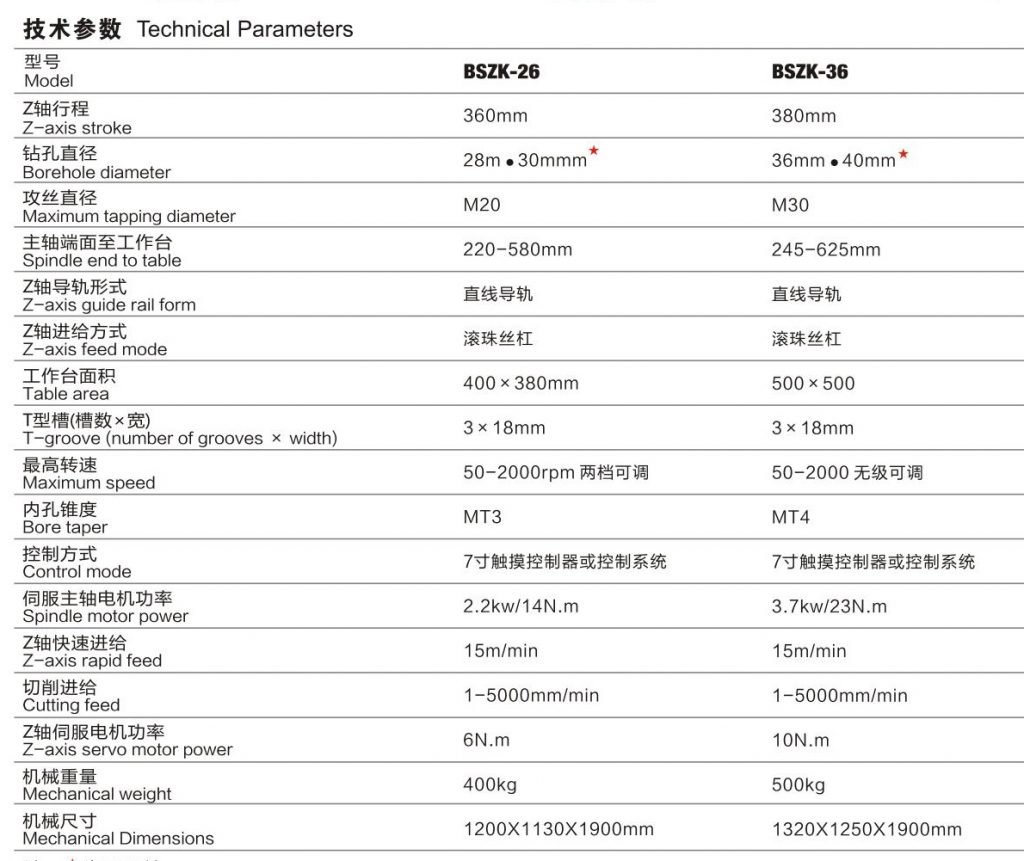

TECHNICAL PARAMETERS