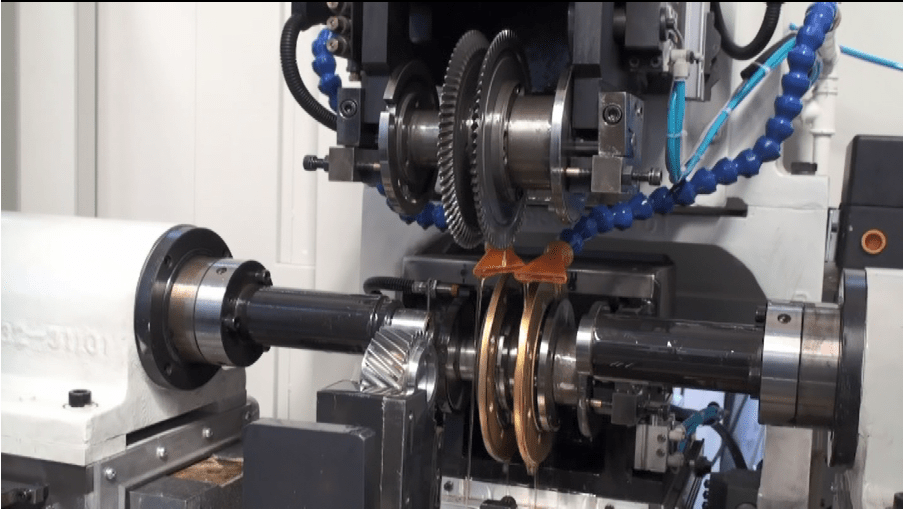

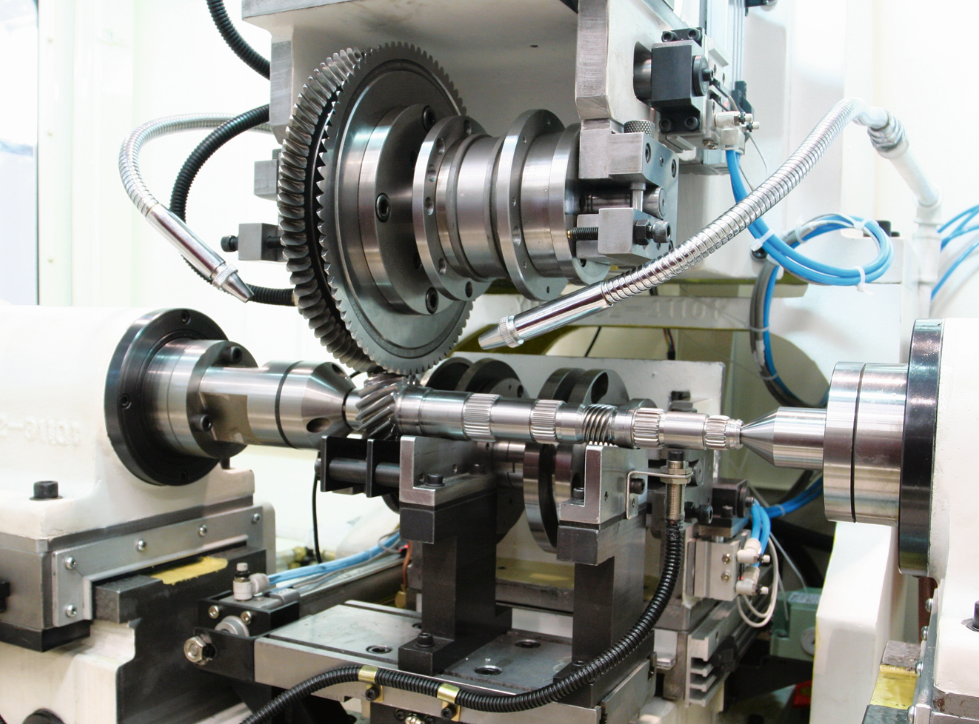

YKL9332 Universal Chamfering and Deburring Machine

Why the YKL9332 Universal Chamfering and Deburring Machine is Necessary in Your Work

The YKL9332 Universal Chamfering and Deburring Machine is specially designed for manufacturing spur and helical gears. This gear chamfering machine features two cutting tool heads, which significantly enhance efficiency and precision.

Effective Deburring

First and foremost, the deburring operation employs advanced, proven tool heads. These heads are spring-loaded, allowing them to adjust for variations in face width. As a result, this ensures a consistent and effective deburring process, which is essential for high-quality gear production. Notably, this consistency reduces the likelihood of defects, ultimately improving productivity.

Enhanced Chamfering

In addition to deburring, the machine utilizes chamfer and chamfer-roller tools. This combination not only provides a superior final result but also gives gears a polished edge that is crucial for optimal performance. Consequently, gears produced with this machine exhibit enhanced durability and efficiency in operation.

Self-Centering Tools

Moreover, the self-centering tools guarantee symmetrical chamfers on both sides of the workpiece. This feature is vital for achieving uniformity across all gear teeth, thus enhancing the overall quality of the gears produced. Furthermore, uniform chamfers contribute to smoother gear engagement, which is essential for reducing wear and tear.

Pneumatic Cylinder Support

Furthermore, the two chamfering and deburring heads mesh with the workpiece using pneumatic cylinders. This innovative design compensates for any workpiece runout, ensuring symmetrical and constant chamfers on every tooth. As a result, this level of precision improves the reliability of the gears in various applications.

User-Friendly Design

Additionally, the YKL9332 comes with a shuttle feed loader for easy manual loading and unloading. This user-friendly feature makes it convenient for operators to maintain workflow efficiency. Furthermore, it can be seamlessly connected to various automation systems or robots, enhancing its adaptability for modern manufacturing environments. This flexibility allows businesses to scale operations without significant adjustments.

Conclusion

In summary, the YKL9332 is not only an efficient and versatile machine but also enhances the chamfering and deburring processes for gears. By ensuring high-quality results in production, it plays a crucial role in optimizing your manufacturing operations. Ultimately, investing in the YKL9332 can lead to improved product quality, increased productivity, and a stronger competitive edge in the market.

Features of the YKL9332 Universal Chamfering and Deburring Machine

The YKL9332 Universal Chamfering and Deburring Machine offers several key features that enhance its efficiency and usability:

Multi-Function Capability

First and foremost, this machine performs chamfering, rolling, and deburring in a single process. This integration not only saves time but also increases productivity significantly.

Automation Compatibility

Moreover, it easily connects to various automation systems or robots. This flexibility allows for seamless integration into existing production lines, enhancing operational efficiency.

Short Cycle Times

In addition, the YKL9332 boasts extremely short cycle times, making it ideal for high-volume manufacturing. Consequently, this feature helps meet demanding production schedules without compromising quality.

Cost-Effective Operations

Furthermore, the machine offers low costs for chamfering, rolling, and deburring, making it an economical choice for manufacturers. As a result, businesses can improve their bottom line while maintaining high standards.

Main Technical Parameters

Here are the main specifications of the YKL9332 gear deburring machine:

- Workpiece Diameter: Gear tooth tip rounded from Ф50 to Ф320 mm

- Machining Gear Module: 6 mm

- Maximum Workpiece Length: ≤ 500 mm

- Distance from Cutter Spindle to Workpiece Center: 100-300 mm

- Mounting Hole for Deburring Cutter: 92 mm

- Mounting Hole for Chamfering Cutter: 100 mm

- Cutter Speed: 200 rpm

- Efficiency: 40 seconds per piece

- Main Motor Power: 10 kW

- Machine Dimensions (L × W × H): 2300 × 1800 × 2000 mm

- Net Weight: ≤ 3200 kg

- Operating Ambient Temperature: -5 to 40 °C

- Air Supply Requirements: Air pressure 0.4 to 0.7 MPa

- Axis Configuration: Two axes

Optional Accessories

The YKL9332 gear deburring machine also offers optional accessories to further enhance its functionality:

- Automatic Loading & Unloading Device

This accessory improves efficiency by automating the loading and unloading process, thereby reducing manual labor. - Safety Light Curtain

This feature ensures operator safety during machine operation, which is critical in a busy manufacturing environment. - Progressive Concentration Lubrication

Additionally, this system provides optimal lubrication for extended tool life, which is essential for maintaining performance. - Large Protection

This feature offers additional safety measures for machine operation, ensuring a secure working environment.

Conclusion

In summary, the YKL9332 is a versatile and efficient machine designed for modern manufacturing needs. By combining multiple functions in one compact solution, it not only improves operational efficiency but also meets the high standards required in today’s competitive market. Investing in the YKL9332 can lead to enhanced productivity, reduced costs, and improved product quality.

And other gear chamfering machine you maybe interested

Reviews

There are no reviews yet.