Mastering Standard Chamfer Size Chart: Definition, Dimensions, and Design Insights

Introduction

For anyone who is either a professional engineer or enjoys the practice of engineering at home, you must embrace the standard chamfer size chart.

Chamfers have applications in manufacturing industries, woodworking industries, and design; they act as functional and aesthetic features.

Chamfers ease parts to fit together; they eliminate sharp edges and make the components look better.

Here, we will explore the meaning of the term chamfer, understand the concept of chamfered edge, and analyze the role of chamfer in different usages, such as in the processes involving machining, hole making, and product designing.

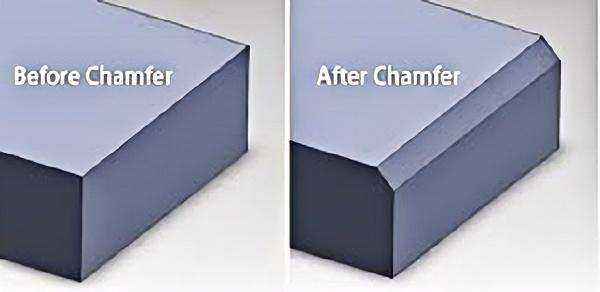

1.What is Chamfer?

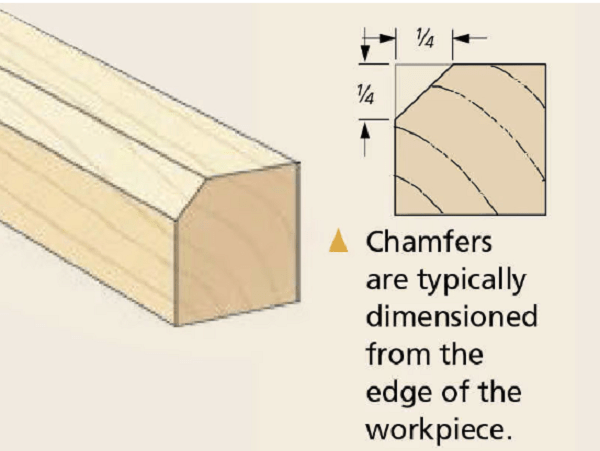

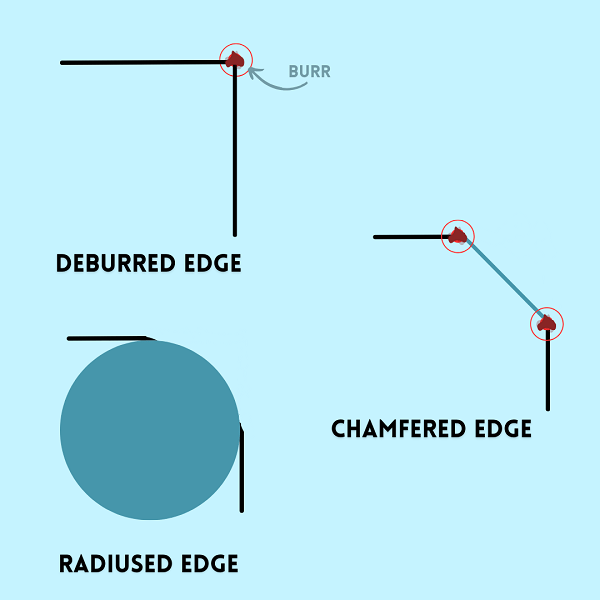

A chamfer is a cutting and forming tool in the shape of an inclined plane, cutting off its corner at an angle that is usually 45 degrees to remove sharp edges.

The meaning behind chamfered edges goes beyond the aesthetic; aside from appearance, they satisfy technical needs such as relieving stress concentration, ease of assembly, and safety because sharp edges are avoided.

In modern design and engineering, the rounded transition is called a fillet, and the distinctly angular one is called a chamfer; the actual difference between the two is that in the first case, the angle is rounded, while in the second case, it is sharp.

Chamfers are made by using tools such as chamfering cutters, and they are frequently used on holes; these are referred to as chamfering holes with a view of making insertion of screws or countersinking easier.

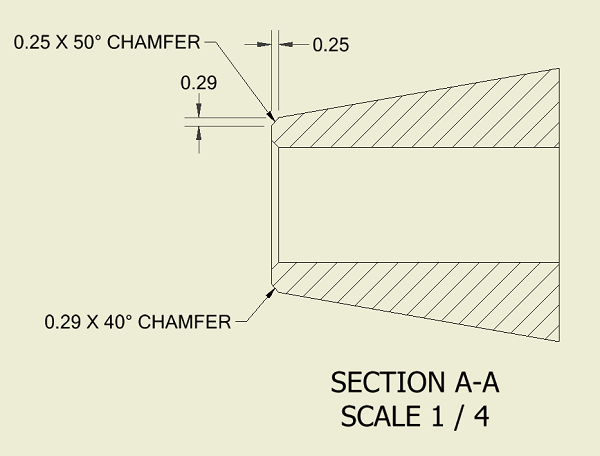

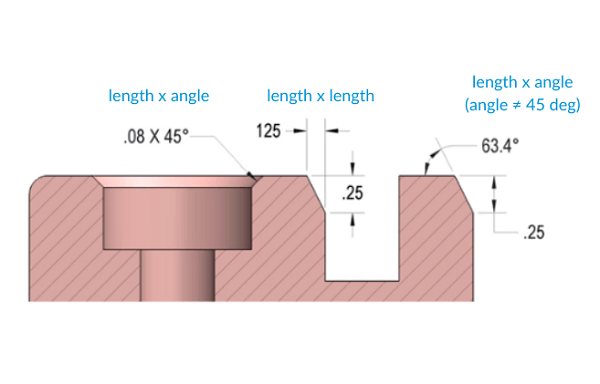

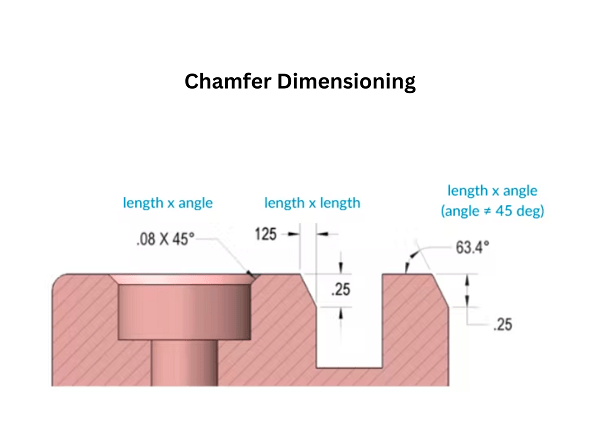

It is important to know how chamfer dimensioning works to control things such as how the chamfer angle is determined and how to measure chamfer.

A chamfer angle varies between 30 and 60 degrees; 45 degrees is most often used in practical applications.

Chamfers help add diversity in design, plus help make a transition in chamfered corners smoother. It's used across industries and sectors such as automotive, aerospace, and furniture industries, to name but a few.

What a chamfered edge is and how it works is important information that you can put to good use in the improvement of your designs as well as meeting professional requirements.

2.Chamfer Size Chart

A chamfer size chart is an essential reference for professionals working in machining, engineering, and design.

It provides precise dimensions for creating chamfers, including the chamfer length and angle, which are critical for achieving accurate and consistent results.

These charts simplify the process of determining the appropriate specifications based on material type, application, or component requirements.

One commonly used standard is the C2 chamfer size, often applied to ensure smooth edge transitions in mechanical parts and fasteners.

The chart typically includes details like the recommended chamfer length and angle, with 45 degrees being the most common angle for general-purpose applications.

By using a chamfer size chart, designers and machinists can ensure precision, improve product functionality, and maintain safety standards. Whether you're crafting beveled edges for aesthetics or performance, the chart is your go-to guide for optimal chamfering.

| Code | Size | SHK(mm) | CED(mm) | B(mm) |

| X00401 | 1/4*1/4 | 6.35 | 21.98 | 6.35 |

| X00402 | 1/4+5/16 | 6.35 | 24.25 | 7.96 |

| X00403 | 1/4*3/8 | 6.35 | 26.5 | 9.52 |

| X00404 | 1/4*1/2 | 6.35 | 30.96 | 12.7 |

| X00405 | 1/4*5/8 | 6.35 | 35.5 | 15.9 |

| X00406 | 1/4*3/4 | 6.35 | 40 | 19.05 |

| X00407 | 1/4*7/8 | 6.35 | 44.4 | 22.2 |

| X00408 | 1/4*1 | 6.35 | 48.9 | 25.4 |

| X00409 | 1/2*1/4 | 12.7 | 21.98 | 6.35 |

| X00410 | 1/2*5/16 | 12.7 | 24.25 | 7.96 |

| X00411 | 1/2*3/8 | 12.7 | 26.5 | 9.52 |

| X00412 | 1/2*1/2 | 12.7 | 30.96 | 12.7 |

| X00413 | 1/2*5/8 | 12.7 | 35.5 | 15.9 |

| X00414 | 1/2*3/4 | 12.7 | 40 | 19.05 |

| X00415 | 1/2*7/8 | 12.7 | 44.4 | 22.2 |

| X00416 | 1/2*1 | 12.7 | 48.9 | 25.4 |

| X00417 | 1/2*1-1/8 | 12.7 | 53.4 | 28.6 |

| X00418 | 1/2*1-1/4 | 12.7 | 57.9 | 31.75 |

| X00419 | 1/2*1-3/8 | 12.7 | 62.4 | 34.9 |

| X00420 | 1/2*1-1/2 | 12.7 | 67 | 38.1 |

| X00421 | 1/2-1-3/4 | 12.7 | 75.86 | 44.45 |

| X00422 | 1/2*2 | 12.7 | 84.84 | 50.8 |

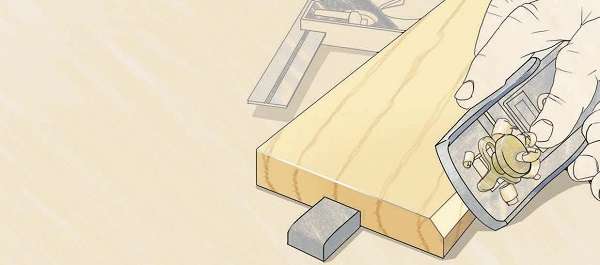

3.How to Make a Chamfer?

Creating a chamfer involves removing material at an angle to produce a sloped or beveled edge. This process can be done manually or using specialized tools.

Chamfer Mills are the go-to tools for precise and efficient chamfering in machining. These tools are designed with angled cutting edges that allow for smooth, consistent operations.

Chamfer Mills makes the Operation Simple by offering versatility, whether you're chamfering holes, edges, or corners. To create a chamfer, set the desired angle, align the tool with the edge, and apply controlled cutting.

For best results, use the proper speed, feed rate, and tool size suited to your material and application. Chamfer mills are ideal for achieving clean, professional finishes while reducing effort and improving accuracy.

4.What is the Advantage of a Chamfer?

Chamfers offer both functional and aesthetic benefits across various industries. By removing sharp edges, chamfers improve safety, making components easier to handle.

They also reduce stress concentration, enhancing the durability of parts and preventing cracks or failures under load.

Chamfers are especially useful in assembly processes, as they guide components into position, such as screws into chamfered holes, ensuring smooth and precise fitting.

In design, chamfers add a polished, professional look to parts, making them visually appealing.

They also simplify manufacturing by using tools like chamfer mills, which ensure consistency and reduce production time.

Whether for structural integrity, assembly efficiency, or appearance, chamfers are a critical feature in engineering and design.

Learn more about the purpose of chamfering.

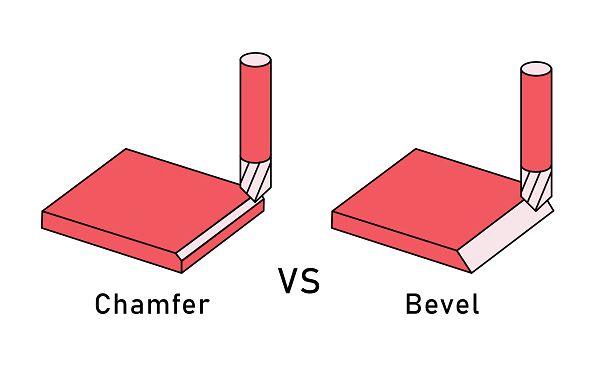

5.Bevel vs. Chamfer

The terms "bevel" and "chamfer" are often used interchangeably, but they have distinct meanings and applications in design and engineering. Both involve angled edges, but the difference lies in their geometry and purpose.

A chamfer is a sloped edge that typically connects two surfaces at a 45-degree angle, while a bevel refers to an angled cut that is often larger and less precise, spanning a broader area.

Hampers are widely employed for safety purposes, for the facilitation of assembly, and for appearance. For example, they are important when making a given cut on a metric thread or an extrusion of a thread since they provide the tools or fastener a nice edge up for engagement.

The chamfer also starts cleanly and puts less wear on tools, which makes it appropriate for use in more accurate operations.

On the other hand, bevels are used in applications in which strength and a more gradual change of the edge are required, for example, in welding or carving a decorative molding of wood.

Like chamfers, bevels may not have a recommended angle and can be used in a variety of ways to a greater extent.

In other words, a chamfer is ideal for fine mechanical purposes, while a bevel is ideal for strength bearing and design purposes. Knowledge of the differences helps one to select the right edge treatment for their project needs.

Conclusion

Chamfers are a very small component of engineering, manufacturing, and design, and they are very important in enhancing functionality, safety, and appearance.

Therefore, knowing the chamfer definition all the way to the differences between fillet vs chamfer or bevel and chamfer, it is evident that chamfers play a very crucial role in developing sophisticated and strong parts together with extreme efficiency. Some tools, such as chamfer mills, make this process easier, more precise, and less time-consuming.

Whether you are chamfering holes, achieving smooth edges, or simply using a chamfer size chart, you need to know the proper chamfer length and angle to achieve a professional finish. This article outlines how chamfers can be used to increase safety, facilitate assembly, and design a better-looking product.

Being an intricate and minute feature in the design, chamfers find wide use, particularly in cutting metric threads, extruding threads, and machining edges.

With this information at your fingertips, you are well-equipped to apply chamfers in any of your projects to obtain the best outcomes.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

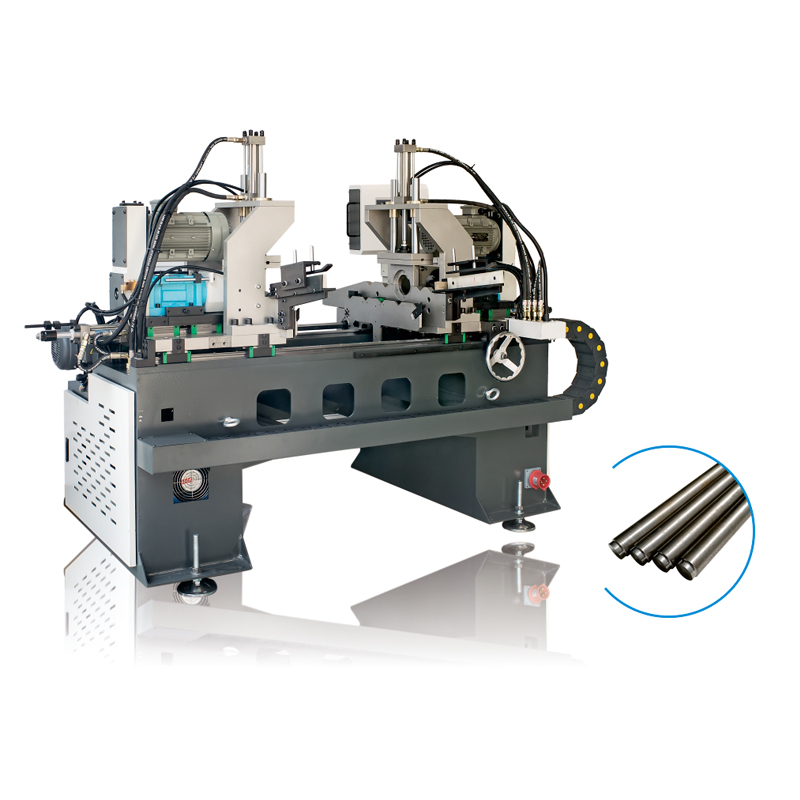

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours