Steel Pipe Size Chart & Types | How to Choose the Right Steel Pipe

Introduction

In plumbing, construction, or industrial systems, having the right steel pipe is essential. These pipes are available in different sizes, thicknesses, and specifications. A steel pipe size chart can help you understand the dimensions you'll need for the materials in your construction project while keeping compatibility and structural integrity in mind.

In fact, a reference guide like this can save valuable time and avoid expensive errors when installing steel pipe fittings or choosing steel pipes. In this article, we’ll look at what a steel pipe size chart is for you to make a better decision. Keep reading to learn more.

1. What is the Steel Pipe?

What is a steel pipe exactly? Steel pipes are cylindrical tubes made of steel that are typically used for transporting fluids and gases, but they are also used for other structural and mechanical functions. Because it's so strong, durable, and can withstand high pressure, it’s often used in construction, plumbing, oil and gas, and the manufacturing industry.

Numerous shapes, sizes, and compositions fulfill the steel pipe definition. In terms of application, different steel pipe types are available. These pipes can be used with steel pipe fittings such as elbows, tees, and reducers for a complex piping system. Steel pipes are an integral component of contemporary infrastructure due to their adaptability and dependability.

Steel Pipe Types

There are several steel pipe types available for various uses and performance requirements.

- Seamless Steel Pipe– This pipe is made without any welded seam, making it high strength and pressure resistant. Used often in high-pressure applications such as oil and gas transport.

- Welded Steel Pipe– Made by welding steel sheets together. It is more economical and well-suited for low to medium pressure applications.

- Galvanized Steel Pipe– A pipe with a zinc coating to prevent corrosion. Commonly used for plumbing and outdoor applications

- Stainless Steel Pipe– Resistant to rust and chemicals, which makes it ideal in food processing, pharmaceuticals, and marine environments.

The appropriate type would depend on the working environment, the needed pressure, and their compatibility with steel pipe fittings and systems.

2. What is the Steel Pipe Size Chart?

The steel pipe size chart allows the user to find the sizes of steel pipes, including nominal bore size, outside diameter (OD), wall thickness, and internal diameter (ID). It aids Engineers, Contractors, and Fabricators in selecting the right pipe size for a particular application for a proper fit, flow, and strength.

Steel pipe sizes are usually measured in standard pipe sizes mm (millimeters) or inches according to the region or industry standard. The chart simplifies the complex data, making it easy for users to identify pipe specifications at a glance. This steel pipe size chart can come in handy if you need to design a piping system or you need to choose fittings and flanges that work well.

| Steel Pipe Size Chart | |||||

| SCHEDULE 40 | SCHEDULE 80 | ||||

| NOMINAL PIPE SIZE |

OUTSIDE DIAMETER |

Wall Thick. |

Wt. Per Ft. |

Wall Thick. |

Weight Per Ft. |

| 1/8 | 0.405 | 0.068 | 0.245 | 0.095 | 0.315 |

| 1/4 | 0.540 | 0.088 | 0.425 | 0.119 | 0.535 |

| 3/8 | 0.675 | 0.091 | 0.568 | 0.126 | 0.739 |

| 1/2 | 0.840 | 0.109 | 0.851 | 0.147 | 1.088 |

| 3/4 | 1.050 | 0.113 | 1.131 | 0.154 | 1.474 |

| 1 | 1.315 | 0.133 | 1.679 | 0.179 | 2.172 |

| 1-1/4 | 1.660 | 0.140 | 2.273 | 0.191 | 2.997 |

| 1-1/2 | 1.900 | 0.145 | 2.718 | 0.200 | 3.631 |

| 2 | 2.375 | 0.154 | 3.653 | 0.218 | 5.022 |

| 2-1/2 | 2.875 | 0.203 | 5.793 | 0.275 | 7.661 |

| 3 | 3.500 | 0.216 | 7.576 | 0.300 | 10.250 |

| 3-1/2 | 4.000 | 0.226 | 9.109 | 0.318 | 12.510 |

| 4 | 4.500 | 0.237 | 10.790 | 0.337 | 14.980 |

| 5 | 5.563 | 0.258 | 14.620 | 0.375 | 20.780 |

| 6 | 6.625 | 0.280 | 18.970 | 0.432 | 28.570 |

| 8 | 8.625 | 0.322 | 28.550 | 0.500 | 43.390 |

| 10 | 10.750 | 0.365 | 40.480 | 0.500 | 54.740 |

| 12 | 12.750 | 0.375 | 49.560 | 0.500 | 65.420 |

3. What Materials are Used for Steel Pipe?

There are different kinds of steel pipes produced with different types of materials. Some of the most common materials are:

Carbon Steel

The most common material used to manufacture steel pipes is carbon steel. This steel has more carbon content than other steels, which results in higher strength and hardness. Carbon steel pipes are used in construction, oil and gas pipelines, and water transport systems. They are inexpensive and can withstand high pressure, which makes them appealing to many industries.

Stainless Steel

The presence of chromium gives stainless steel great corrosion resistance. This kind of steel pipe is usually used in medical, chemical plants, and food processing. Even under extreme temperatures and chemical exposure, a stainless pipe remains intact.

Alloy Steel

Alloy steel pipes are carbon steel pipes that include molybdenum, nickel, or chromium. They improve attributes like strength, hardness, and resistance to heat and corrosion. Alloy steel is durable and performs under heavy industrial applications as well as in power plants.

4. What is the Application of the Steel Pipe?

Steel pipes are used in a variety of sectors because of their strength, durability, and adaptability.

Plumbing Systems

Steel pipes are commonly used in plumbing systems to transport water, gas, and waste. These pipes are strong and can withstand internal pressure, making them perfect for residential and commercial plumbing networks. Steel pipe fittings and hydraulic coupling fittings are also often used in conjunction with the nip fittings to form leak-free and strong connection points.

Construction Industry

In construction, steel pipes can be used as structural elements in buildings, bridges, and other infrastructure. Its ability to support heavy loads and resist corrosion makes it a go-to material for structures, columns, and scaffolding systems.

Oil and Gas Industry

Seamless and alloy steel pipe types are widely used in the oil and gas industry for drilling, transportation pipelines, and processing systems. These pipes are intended to endure extreme temperatures, pressure, and corrosive environments.

Automotive Manufacturing

In the automotive industry, steel pipes are essential for components like exhaust systems, suspension, and fuel lines. Their durability and precision are critical for ensuring the safety and efficiency of these vehicles.

HVAC and Fire Protection

Steel pipes are used in HVAC systems, as well as fire sprinkler systems, because of their resistance to temperature variations and high-pressure fluids. They are compatible with various steel pipe fittings and allow for flexible design and installations.

Agriculture and Irrigation

Steel pipes are also used in agriculture, especially when it comes to irrigation systems and greenhouse structures. Because they last so long and don't get damaged easily, they are perfect for the outside or if used in harsher environments.

5. How to Choose the Right Steel Pipe?

However, selecting the right one is critical to safety, efficiency, and long-term performance. Here are some key factors to consider:

Identify the Application

The first and most critical step is knowing the pipe's application. Steel pipes have various specifications for different uses. For instance, high-pressure systems require durable materials such as seamless steel pipes, while welded steel pipes may be enough for low-pressure systems. In structural applications, the pipes must be capable of carrying significant weight.

Choose the Material

Material selection depends on the environment and application. Ideally, carbon steel is durable and affordable. The ideal type of pipe for construction and industrial piping. Alloy steel is good for high-temperature or high-stress conditions. Select the material that best suits the particular working conditions.

Refer to the Steel Pipe Size Chart

A steel pipe size chart is used to identify the correct dimensions of a pipe. It contains the outside diameter (OD), wall thickness, and inside diameter. If you select the wrong size, you risk an excessive pressure drop or fit problems. Always verify before purchase. You can use the chart to ensure the right selection for your piping system.

Check Compatibility with Fittings

The pipe must be compatible with the appropriate steel pipe fittings, such as elbows, tees, flanges, couplings, and more. Leaks, or worse, failure can occur with incompatible fittings. So, carefully match the pipe and fitting dimensions.

Consider Standards and Certifications

Things to keep in mind: Certified pipes guarantee security and performance. Using inferior pipes would lead to failure and regulatory problems. Always inquire about certification when you buy.

Conclusion

A steel pipe size chart is essential for selecting the right pipe for any application. Steel pipe is durable, strong, and reliable, whether it's used in plumbing, construction, or industry. Choosing the right steel pipe type depends on the environment and system. Make sure you use the right steel pipe fittings to keep your connections tight and leak-free. Always refer to standard pipe sizes in mm for accuracy. Making informed decisions leads to longer-lasting and more efficient systems.

For detailed guidance and accurate steel pipe size, please visit Armpro Machine. Our range of accessories and expert advice ensures that you will find the perfect solution for your needs.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

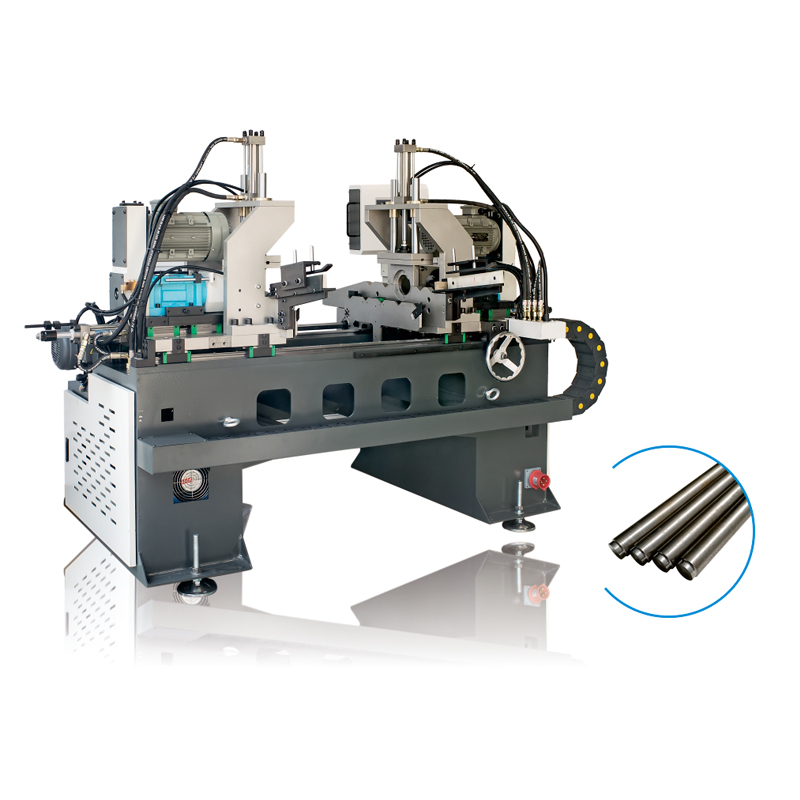

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours