Find The Most Accurate Steel Pipe Sizing Chart

Introduction

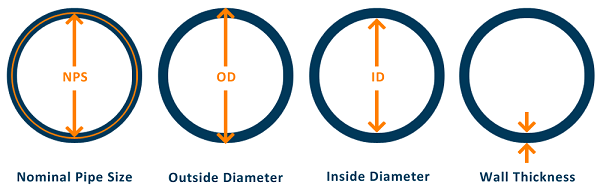

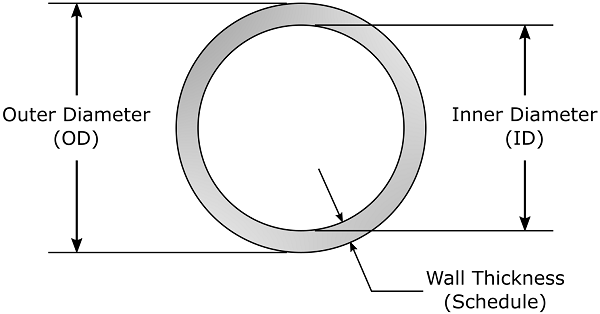

The steel pipe size chart is a very useful tool for understanding the different dimensions of steel pipes, such as outer diameter, wall thickness, and inner diameter.

This helps professionals and engineers select the right pipe for a specific project, ensuring that it will be compatible with the fittings and other components. The chart includes steel pipe sizes in mm and standard pipe sizes in mm, making it usable both domestically and internationally.

Whether for plumbing, construction, or industrial use, this chart is indispensable for the selection of pipes with accuracy and speed.

1. What is the steel pipe?

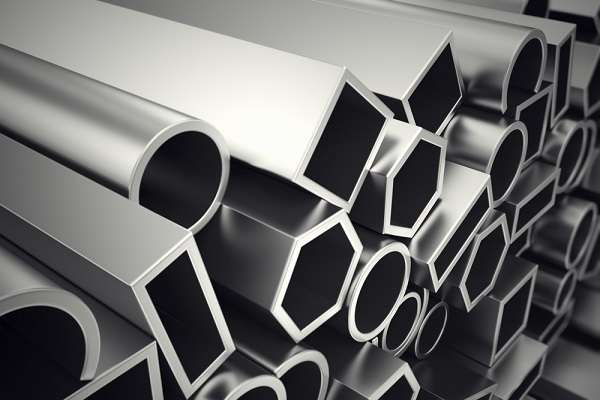

The steel pipe essentially forms a cylindrical tube made from steel for the transportation of liquids, gases, and other materials for many applications, such as in construction, plumbing, and industrial systems.

Types of Steel Pipes

- Carbon Steel Pipe: It is strong and durable; hence, it is applicable in structural and industrial applications where it serves as a cheaper substitute for heavy-duty purposes.

- Stainless Steel Pipe: Stainless steel pipes are very resistant to corrosion and staining, so they can be used where moisture or chemicals are present, such as in food processing, medical, and high-temperature applications.

Key Considerations:

- Steel Pipe Diameter: The diameter of the steel pipe is very important in determining its flow capacity and suitability in a given application.

- Steel Pipe Dimensions: Wall thickness, inside diameter, and overall length ensure the correct fit and performance for any given project.

- Standard Pipe Lengths: Uniformity in pipes makes them easier to install, handle, and fit for large-scale projects.

2. What materials are used for steel pipe?

Steel pipes can be fabricated from various materials that have distinct properties making them fitting for different applications. The main materials used for steel pipes include:

Carbon Steel

- Properties: Strong, durable, and economical.

- Uses: Widely used in construction, water pipelines, and gas transport due to its strength and versatility.

Galvanized Steel

- Properties: steel that has undergone a process where a zinc coating is applied for improved protection from corrosion

- Uses:Mostly for outdoor or underground pipelines, fencing, and construction projects where corrosion resistance is required.

Stainless Steel

- Properties: Resistant to corrosion, staining, and high temperatures.

- Uses: In applications where resistance to moisture, chemicals, and extreme temperature conditions is needed—in other words, food processing equipment, medical equipment, and marine uses.

Duplex Steel

- Properties: A combination of austenitic and ferritin steel. It is mainly used due to its excellent strength, high corrosion resistance, and improved weldability.

- Uses: It can be used in any extreme environment, such as oil and gas pipelines and marine applications.

Alloy Steel

- Properties: Mixes with elements like chromium, nickel, or molybdenum to increase strength and resistance to wear, heat, and corrosion.

- Uses: Applied in applications like automotive, power generation, and high-pressure systems

The material is chosen based on strength needs, environmental conditions, and the fluid or gas being conveyed.

3. What is the application of the steel pipe?

Steel pipes offer a wide range in many fields and industries due to their strength, durability, and versatility. Some of the common applications are listed below:

Construction

- Structural Support: Steel pipes function as structural support elements that serve in buildings and bridges together with other structures requiring similar support infrastructure.

- Plumbing System: The plumbing system utilizes steel materials because they provide long-lasting resistance to pressure within water supply systems sewage systems and gas lines.

Oil and Gas

- Pipeline Transport: Companies implement steel pipes for pipeline transport activities to move crude oil natural gas and refined products through underground and underwater applications.

- Offshore Platforms :Offshore platforms function as exploration and extraction facilities for oil and gas resources on offshore platforms with the strength required to operate under difficult environmental situations.

Marine

- Shipbuilding: Steel pipes are used in the construction of ships for many onboard systems, such as water supply, sewage management, and cooling.

- Offshore Drilling: Steel pipes play a crucial part in offshore drilling operations in conveying crude oil and gas.

Automotive

- Exhaust Systems:The implementation of steel pipes inside automotive exhaust systems serves multiple purposes especially high heat and chemical resistance.

- Fuel Lines:Due to their pressure resistance capability and high strength level steel pipes serve as fuel lines in vehicle systems.

Agriculture

- Irrigation Systems: Steel pipes are widely used in agricultural irrigation systems, ensuring a smooth and efficient flow of water to crops.

Water and Sewage

- Water Distribution: Due to both their strength and durability steel pipes function as main components within municipal water distribution systems for water distribution as well as wastewater management.

- Sewage and Drainage: The disposal operations need steel pipes to fulfill both waste disposal needs and pressure-resistance purposes for high-pressure situations.

Industrial Application

- Power Generation: Steel pipes have widespread usage in the power industry, encompassing steam and gas turbines, cooling systems as well as boilers.

- Chemical and Pharmaceutical: In the manufacturing facilities of chemicals, steel pipes are utilized while conveying chemicals, gases as well as liquids, which are probably corrosive in addition to holding high temperatures.

Food and Beverage

- Food Processing: Generally, most food processing plants make use of stainless steel pipes due to their hygiene, resistance to corrosion, and ease of cleaning.

Each of these wide applications shows the steel pipes in different industries to be of importance, offering a reliable and long-lasting solution that would involve transporting and supporting the flow of different materials and fluids.

4. What are steel pipe standards?

Steel pipe standards are a set of guidelines and specifications that outline the dimensions, materials, strength, and quality requirements for steel pipes used in different industries: construction, manufacturing, oil and gas, and water systems.

These standards ensure the steel pipes satisfy the requirements in terms of safety, performance, and reliability.

Some of the key steel pipe standards include:

ASTM (American Society for Testing and Materials):

- ASTM A53:Mechanical and pressure applications involving carbon steel pipes wound into coils.

- ASTM A106:For applications involving elevated temperatures, this seamless carbon steel pipe is ideal.

- ASTM A312:Pipes made of austenitic stainless steel that are either welded or coil-shaped.

API (American Petroleum Institute):

- API 5L: For the purpose of transporting oil and gas, this specification lays forth the necessary specifications for line pipes.

ISO (International Organization for Standardization):

- ISO 3183: This is the specification for steel pipes used in the petroleum and natural gas industries.

EN (European Standards):

- EN 10217:Relates to steel pipes welded for pressure applications.

- EN 10255:Concerns pipes used for gas pipeline construction purposes.

The specifications include the dimensions of the pipe like diameter, wall thickness, etc, the material attributes, methods for testing, and allowed tolerances. Based on application, the pipes may be given quality and safety certificates.

| Nom. Size (in.) |

Schedule | Est.Wt (lbs./ft.) |

0.D (in.) |

L.D (in. |

Wall Thk. (in.) |

| 1/8 | 40 | 0.245 | 0.405 | 0.269 | 0.068 |

| 1/4 | 80 | 0.320 | 0.405 | 0.215 | 0.095 |

| 40 | 0.425 | 0.540 | 0.364 | 0.088 | |

| 3/8 | 80 | 0.540 | 0.540 | 0.302 | 0.119 |

| 40 | 0.568 | 0.675 | 0.493 | 0.091 | |

| 1/2 | 80 | 0.750 | 0.675 | 0.423 | 0.126 |

| 5 | 0.540 | 0.840 | 0.710 | 0.065 | |

| 3/4 | 40 | 0.851 | 0.840 | 0.622 | 0.109 |

| 80 | 1.100 | 0.840 | 0.546 | 0.147 | |

| 5 | 0.690 | 1.050 | 0.920 | 0.065 | |

| 40 | 1.131 | 1.050 | 0.824 | 0.113 | |

| 1 | 80 5 10 |

1.490 0.880 1.420 |

1.050 1.315 1.315 |

0.742 1.185 1.097 |

0.154 0.065 0.109 |

| 1-1/4 | 40 | 1.679 | 1.315 | 1.049 | 0.133 |

| 80 | 2.190 | 1.315 | 0.957 | 0.179 | |

| 5 | 1.120 | 1.660 | 1.530 | 0.065 | |

| 40 | 2.273 | 1.660 | 1.380 | 0.140 | |

| 1-1/2 | 80 | 3.030 | 1.660 | 1.278 | 0.191 |

| 5 | 1.274 | 1.900 | 1.770 | 0.065 | |

| 10 | 2.100 | 1.900 | 1.682 | 0.109 | |

| 2 | 40 80 5 10 |

2.718 3.760 1.620 2.660 |

1.900 1.900 2.375 2.375 |

1.610 1.500 2.245 2.157 |

0.145 0.200 0.065 0.109 |

| 2-1/2 | 40 80 40 80 |

3.653 5.070 5.793 7.660 |

2.375 2.375 2.875 2.875 |

2.067 1.939 2.469 2.323 |

0.154 0.218 0.203 0.275 |

| 3 | 5 | 3.060 | 3.500 | 3.334 | 0.065 |

| 3-1/2 | 40 80 10 |

7.576 10.250 4.973 |

3.500 3.500 4.000 |

3.068 3.760 |

0.216 0.300 0.120 |

| 4 | 40 10 40 |

9.109 5.670 10.890 |

4.000 4.500 4.500 |

3.548 4.260 4.026 |

0.226 0.120 0.237 |

| 5 | 10 | 7.840 | 5.563 | 5.295 | 0.134 |

| 40 | 14.750 | 5.563 | 5.047 | 0.258 | |

| 6 | 10 | 9.380 | 6.625 | 6.357 | 0.134 |

| 40 | 19.150 | 6.625 | 6.065 | 0.280 | |

| 8 | 80 10 40 |

28.600 13.400 28.820 |

6.625 8.625 8.625 |

8.329 7.981 |

0.432 0.148 0322 |

| 10 | 80 10 40 |

43.430 18.650 40.860 |

8.625 10.750 10.750 |

10.420 10.020 |

0.500 0.165 0.365 |

| 12 | 80 10 40 |

64.490 24.160 50.030 |

10.750 12.750 12.750 |

12.390 12.000 |

0594 0.180 0375 |

| 1416 | 80 | 88.710 | 12.750 | 0.688 | |

| 40 | 63.500 | 14.000 | 0438 | ||

| 10 | 42.090 | 16.000 | 0250 | ||

| 40 | 82.850 | 16.000 | 0.500 | ||

| 1820 | 10 | 47.440 | 18.000 | 0.562 | |

| 10 | 52.780 | 20.000 | 0.594 |

5. How to choose the right steel pipe?

To choose the right steel pipe, follow these steps:

· Determine the Application:

Identify the intended use, such as construction, plumbing, or oil and gas. This will affect the pipe's material and specifications.

· Select the Material:

Choose the appropriate material based on environmental factors:

- Carbon Steel: Cost-effective and widely used for general applications.

- Stainless Steel: Perfect for use with a resistance to corrosion, such as within the food processing or chemical industries.

- Alloy Steel: Best for the toughest applications with extremely high pressure and temperature.

· Consider Pipe Size and Dimensions:

- Diameter: Consider a radius that will accommodate the flow rate that is needed or desired.

- Wall Thickness: Thicker walls provide better withstanding for higher internal pressure and strength.

· Check Standards and Certifications:

Make sure that the pipe satisfies relevant standards (e.g., -ACTM, Api) for quality and safety for the industry.

· Corrosion Resistance:

Should the pipe be subject to adverse conditions, consider stainless steel or pipes with protective coverings, for example, galvanized, to avoid corrosion.

· Cost and Performance:

Optimize the cost of the pipe and its expected lifespan and performance needs.

Keeping all these considerations in mind will help you choose a steel pipe that ensures safety, reliability, and effective system performance.

Conclusion

In conclusion, the dimensions needed for the pipes—outer diameter, wall thickness, and inner diameter—can be precisely satisfied with the help of the steel pipe size chart.

By guaranteeing compatibility with all fittings and other parts, it simplifies the selection of pipes for specific applications.

The chart's inclusion of both millimeters for steel pipe diameters and millimeters for standard pipe sizes makes it applicable on a global scale. With the help of the size chart, professionals in a variety of fields can make judgments that boost efficiency, output, and security.

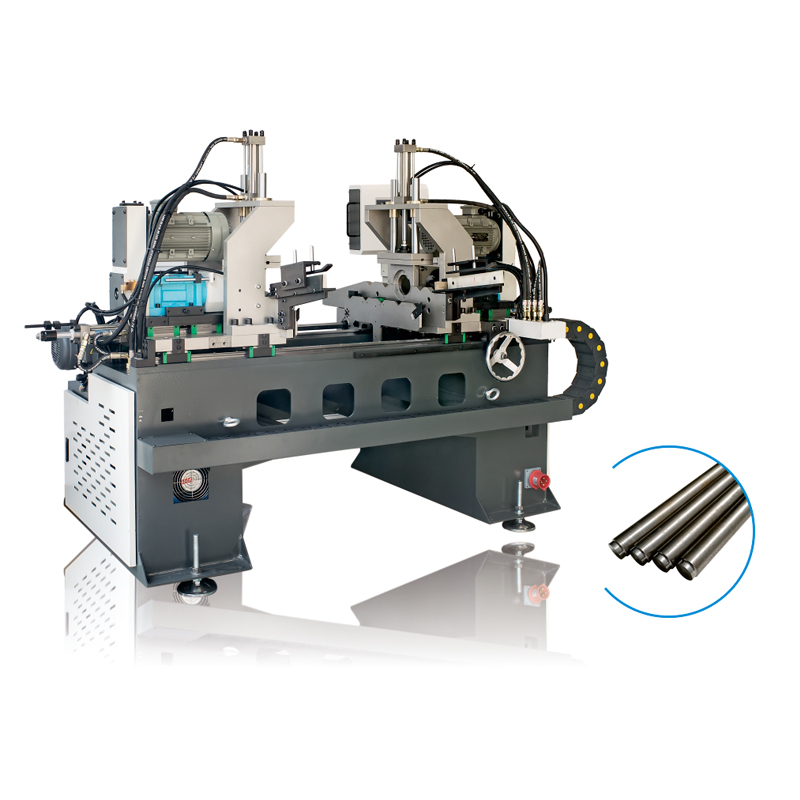

For detailed guidance and accurate pipe size tables, please visit Armpro Machine. Our range of accessories and expert advice ensures that you will find the perfect solution that meets your needs.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours