Decoding Welding Symbols: A Complete Guide to Fillet, Groove, and More

Introduction

Welding operation is considered the prime factor in the manufacturing, construction, and metal industries, where synchronization and clarification for the proper functioning of the apparatus are necessary.

This is where the welding symbols chart comes in handy. Welding symbols are standardized diagrams that reflect the specific instructions for performing a certain welding activity.

This understanding is critical when it comes to either enhancing structures or conforming them to these specified features of a project.

Here in this blog, we will be looking at what welding symbols are, why they are significant, and what components constitute this form of sign language.

1. What are Welding Symbols?

Welding symbols are signs used in engineering drawings, and there are standardized signs that proclaim the performance of welding work.

These symbols are dimensioned; that is, they indicate the type, size, and location of a weld, and this is obviously so much better than using words in a sentence or a paragraph to describe a weld.

Using the welding symbols chart, these welders will be in a position to understand such symbols and do the wiring in the right manner.

Welding symbols are crucial because they remove uncertain factors from the construction of items. They help to keep things standardized across different teams and projects, save one from making embarrassing mistakes, and make work smarter.

For this reason, even if you are only welding part of an automobile or performing a large fabrication or structural construction project, the use of welding symbols cannot be overemphasized.

2. Elements of a Welding Symbol

Welding symbols are made up of several parts, each of which communicates specific information about a particular weld. These components combine to offer the user a full picture of the welding requirements of the car.

The common characteristics of a welding symbol are the reference line, attention line, and the tail of the symbol. Collectively, they determine the kind of weld to be made, the size of the weld, where the weld is to be made, as well as any other special instructions.

Basic Elements of a Welding Symbol

● Reference Line

The reference line is the backbone of a welding symbol, serving as the primary guide for interpreting the welding instructions.

It is a horizontal line that connects the other elements of the symbol, such as the arrow and tail. The details about the weld type, size, and other specifications are placed above, below, or along this line.

● Arrow

The arrow points to the exact location where the weld needs to be applied to the workpiece. It connects the reference line to the joint or area being welded.

The direction and placement of the arrow are crucial, as they indicate whether the weld applies to the arrow side, the other side, or both sides of the joint.

● Tail

The tail is an optional component of a welding symbol and is used to include additional information or instructions. This may include details about the welding process, specifications, or any required finishing procedures. While not always present, the tail is essential for communicating unique or project-specific requirements.

With mastery over all the elements and weld symbols chart, the welders and engineers are fully equipped and assured that whatever weld is done will definitely meet the design specification with enhanced quality and reliability.

3. Welding Symbols Chart

The welding symbols chart is a guide to help the users read and interpret welding symbols correctly. It gives a graphical representation of standardized welding notations, which ensures that weld designers, engineers, and fabricators understand and effectively implement designs on welds.

Welding symbols are classified depending on the type to depict; the kind of welds is crucial to understand for work completion.

Further, let's categorize some of the fundamental welding symbols here: groove weld symbol, fillet weld symbol, and, yes, the role of chamfer mills.

● Groove Weld Symbol

The groove weld symbol means a weld that utilizes a groove formed between two adjacent parts in joining the metal. It is usually applied in the butt joint, T-joint, and corner joint for deep penetration and high strength of the joint.

For this reason, groove welds can assume different forms, such as square, V, U, J, and bevel grooves, all of which have unique general symbols on a welding symbols chart.

As with all weld symbols, the groove weld symbol identifies materials, angle, size, and other factors to meet the structural and design needs of the groove weld.

● Fillet Weld Symbol

The filter weld symbol is one of the most familiar welding symbols, showing welds that connect two surfaces at 90 to each other.

Fillet welds occur in T-joints, lap joints, and corner joints where high strength and relative ease of fabrication are necessary. Additional information specifies the exact size of the weld, its length, and even its rotation angle.

The importance of fillet weld symbols cannot be overlooked as they help users of the welding symbols chart in the performance of welds that will meet the design requirements.

● Chamfer Mills

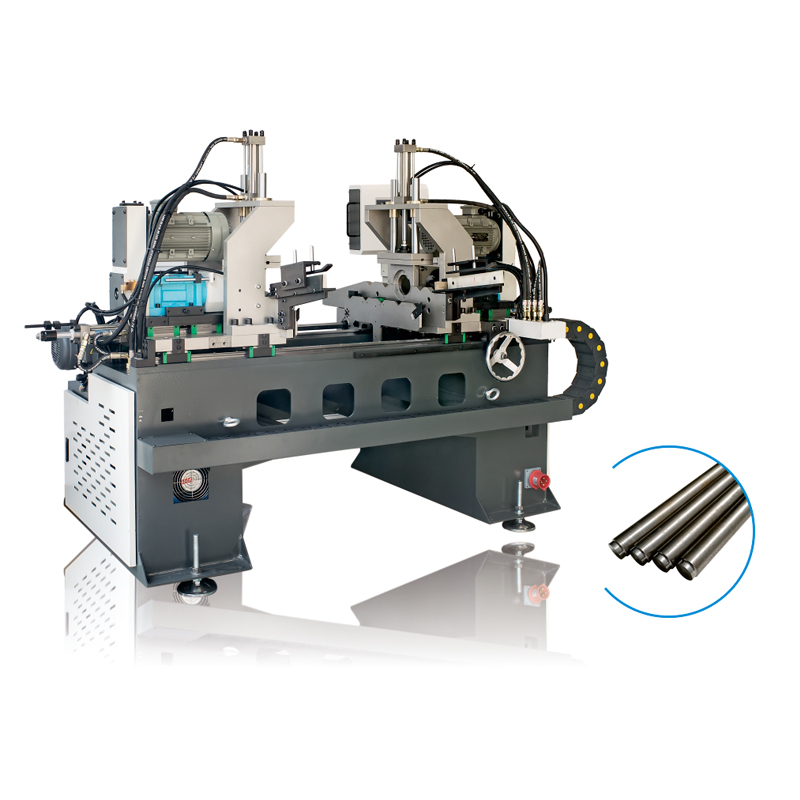

Although it is not one of the weld types, chamfer mills are especially important for the preparation of edges for welding. Chamfer mills are cutting tools utilized to provide bevels or chamfering of workpieces for easy formation of groove welds or preparation for fillet welds.

Surface preparations are important to the success of welding operations because chamfer mills are used to prepare the edges for the correct weld angle. While the details laid out on the welding symbols chart relate to design, these complement the items by providing a link to the practical aspects of the process.

It is crucial that these fundamental welding symbol types and uses are described perfectly as they strengthen the foundation of fabricating strong and correct welds.

Therefore, with the help of the welding symbols chart, it is possible to increase the effectiveness of the results, as well as the welders' and fabricators' experience and the stability of the project.

4. How to Read Fillet Weld Symbols

These are easily the most recognizable weld symbols in most welding projects, and mastering them is vital to making precise welds. The fillet weld symbol normally consists of an enclosed triangle placed with other symbols on the welding symbols chart to represent the weld.

Additional information associated with the weld is shown using asterisks and includes the size of the weld, the length, and the position across the reference line. For instance, the size of the weld is written to the left of the symbol, and the length is to the right.

The vertical position of the weld symbol in relation to the arrow side or the other side of the symbol indicates whether the weld is on the arrow side, the other side, or on both sides. Understanding these specifications guarantees successful interpretation as well as application of the weld.

5. How to Read Groove Weld Symbols

Groove weld symbols represent joints that require a groove between two pieces of metal. These symbols appear on the welding symbols chart as lines and shapes indicating the groove type, such as V, U, J, or bevel.

Information like groove angle, depth, and root opening is specified along or near the reference line.

For example, the included angle may be noted above the reference line, while the groove depth is placed below. An arrow pointing to the joint specifies the location of the weld.

Learning to read groove weld symbols is essential for executing strong, precise joints in projects requiring high structural integrity.

Conclusion

Explaining and interpreting welding symbols is a crucial requirement for anyone practicing fabrication, construction, or engineering.

The welding symbols chart acts as a standard reference in decoding and the level of information to be passed to another team, as having termed some of the welding signs with a very thin line of distinction is very complex.

Thus, opportunities for applying knowledge of fillet and groove weld symbols interpretation and recognition of tools such as chamfer mills lead to high-quality results and efficient operations.

Learning much about these symbols not only results in improved accuracy in design and welding but also in the structures' reliability and the reliability in terms of the welds made.

From this information, welders and engineers can be armed with the best information that will ensure the designs are realized with a lot of precision.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours