Hypotube Size Chart Explained | What is a Hypotube & How to Choose One

Introduction

If you work in a medical profession or high-precision manufacturing, you will likely encounter something called a hypotube. It's a fairly rare vocabulary word outside the industry, but it plays a vital role in saving lives, making machines run efficiently, and performing delicate operations in various fields.

So let's break it down. What is a hypotube? Why is it important? And how do you even begin to understand the hypotube size chart?

This guide gives you clear answers to all these series of questions. We'll talk about the definition of hypotubes, the various hypotube sizes, and how to select one suitable for your use. You will also learn about raw materials used, common standards, and things to be considered before choosing one.

No complicated words. No fluff. Just straight-up useful information in layman's terms.

1. What is a Hypotube?

Let’s start with the basics.

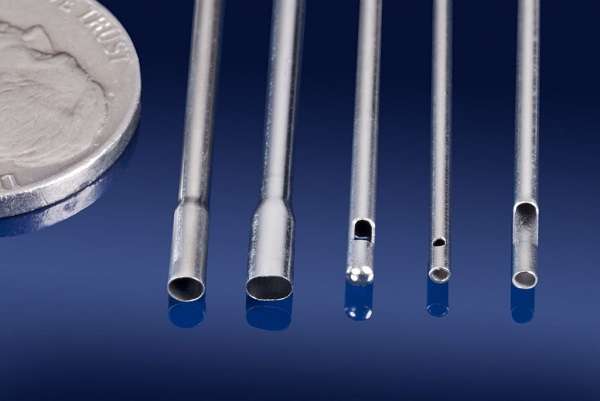

It is a tiny tube that offers high promise in terms of strength, flexibility, and precision of required measurements, especially in the case of medical devices.

Here’s a simple hypotube definition: it’s a tiny metal tube with high strength and excellent torque, designed for movement and control accuracy. Most often, it is used inside the human body during surgery or diagnosis. You’ll also see it in aerospace, robotics, and electronics.

The hypotube symbol is often found in technical drawings. It helps engineers and designers understand specs like the outer diameter (OD), inner diameter (ID), and wall thickness — the three key parts of hypotube sizes.

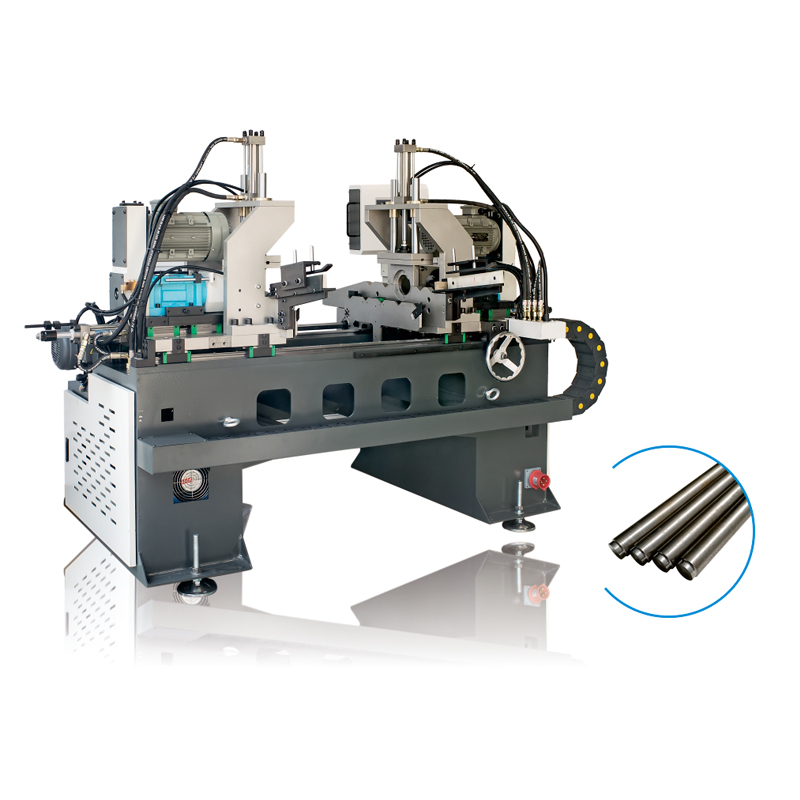

Making one of these tubes isn’t easy. It’s done with a hypotubing machine, which cuts and shapes metal to extreme tolerances. That means the final product is strong, smooth, and ready for high-performance tasks.

In short, if you're handling fine, detailed work where strength and small sizing are essential, you will be using a hypotube.

2. What is the Hypotube Size Chart?

Here’s where things get more technical — but still easy to follow.

A hypotube size chart shows all currently available hypotube sizes. It gives the outer diameter, inner diameter, and wall thickness for every single size. These dimensions matter because even small differences can significantly impact performance.

Most charts use standard gauge sizes (like 18G, 20G, etc.), and they might look like this:

| Gauge | OD (inches) | ID (inches) | Wall Thickness (inches) |

| 24G | 0.022 | 0.016 | 0.003 |

| 22G | 0.028 | 0.020 | 0.004 |

| 20G | 0.035 | 0.025 | 0.005 |

| 18G | 0.050 | 0.040 | 0.005 |

Understanding this hypotube size chart helps you choose the right tubing for your application. Need a lot of flexibility? Go for thinner walls. Need more strength and pushability? Choose a thicker wall.

In medical settings, for example, a catheter may need a small outer diameter but a large inner diameter to allow fluid to pass. In manufacturing, the right tube has to fit perfectly with connectors or guide parts inside tight spaces.

That’s why the hypotube size chart is such a vital tool. It helps prevent errors and ensures top performance.

| 序考 | 00外径Imel ⑥内径fmel | 1长度 (mml |

|

| 中值 | 中值 | ||

| 1 | 0534 | 03556 | 1102 |

| 2 | 0545 | 030 | 1135 |

| 3 | 05842 | 645454 | 1105 |

| 4 | 059 | 042 | 1225 |

| 5 | 0610 | 0460 | 120 |

| 6 | 0610 | 0460 | 1720 |

| 7 | 05 | 04 | 1106 |

| B | 066 | 050 | 1120 |

| B | 065 | 043 | 1300 |

| 10 | 66 | 04 | 1805 |

| 11 | 0164845 | 04855 | 1105 |

| 12 | 056 | 00 | 1706 |

| 1 | 0E6D4 | 0.428 | 1220 |

| 14 | 66604 | 04328 | 1226 |

| 15 | 065 | 050 | 1097 |

| 16 | 06731 | 05046 | 1135 |

| 17 | BT | 043 | 1294 |

| 18 | 6E21 | D50648 | 1425 |

| 19 | 69 | 063 | 1106 |

| 20 | 080 | 052 | 1114 |

| 21 | 0.861 | 0711 | 1220 |

3. What Materials Are Used for Hypotube?

The material that you choose for a hypotube counts as much as its size. Most hypotubes are made from stainless steel, grade 304 and 316, more commonly. These are strong, corrosion-resistant, and biocompatible materials, which make them very suitable for medical instruments and implants.

But other materials are also used:

- Nitinol: super flexible with shape memory, excellent for stents and guide wires.

- Titanium: lightweight and strong, with good corrosion resistance.

- Platinum-Iridium: Used when radiopacity is needed, especially in imaging.

Every new material brings its advantages. So, the best choice depends on the need of the project - whether strength, flexibility, or visibility was imagined.

So when choosing a hypotube, don’t just think about size. Think about what it’s made of, too.

4. What is the Application of the Hypotube?

You’ll find hypotubes in a wide range of industries. Let’s go over the most common ones:

Medical Field

- Guidewires: Navigate through blood vessels.

- Catheters: Deliver fluids or medications.

- Biopsy tools: Collect tissue samples.

- Laparoscopic tools: Doing surgeries through tiny openings.

Because of their smooth surface and strength, Hypotubes are perfectly suited for use in a medical setting. They can enter the body safely and move precisely, with little risk of damage.

Aerospace and Defence

- Sensors: Housing for temperature and pressure sensors.

- Fluid transport: Carry gases and fluids in compact systems.

Electronics and Robotics

- Miniature driveshafts

- Cable supports

- Precision tools

Anywhere that needs small, strong, and smooth tubing — that’s where a hypotube works best.

5. What are Hypotube Standards?

When you buy or manufacture hypotubes, you can’t just guess the specs. That’s where hypotube standards come in.

The most common are:

- ISO 9626: Medical tubing — sets rules for dimensions and mechanical strength.

- ASTM A269and ASTM A213: General stainless steel tube standards.

These standards ensure each hypotube is made consistently. This means proper fit, good functionality, and no failure under load.

If you're designing a life-saving device or assembling precision parts, these standards truly matter. So always check them before placing an order.

6. How to Choose the Right Hypotube?

Choosing the right hypotube is difficult. It, however, becomes easier if it is divided into simpler parts.

Start With These Questions:

- What is the purpose of the tube?

- Will it bend or stay rigid?

- Does it carry fluid or support a structure?

- What space or gauge size does it need to fit?

Then use these steps as an instruction manual:

- Check the hypotube size chart: Find the OD, ID, and wall thickness to give you what you want.

- Pick the right material: Stainless steel for general use, nitinol for flexibility, and titanium for a strong/solid arrangement.

- Think about performance: Thinner walls bend better. Thicker walls push better.

- Follow standards: Make sure the hypotube meets industry standards like ISO or ASTM.

- Ask for samples: Always test before a full-scale order.

You may also check with your supplier about custom sizes and finishes. An excellent manufacturer will be there to help you select the ideal specs for your design.

Conclusion

Let’s wrap it up.

What is a hypotube?" It is a high-precision metal tube used in the medical, aerospace, and tech industries. It may seem simple, but in fact, the size, material, and design of the hypotube can make or break your project.

The hypotube size chart helps you compare and choose the right specs. Knowing the hypotube definition, how the hypotubing machine works, and reading the hypotube symbol correctly gives you full control over your project.

If you want to get the best performance from your device, you need the right hypotube. So use this guide, go through your hypotube sizes, check the chart, follow standards, and pick the material that fits your needs.

Still got questions? Keep learning through more guides or contact a hypotube manufacturer for advice tailored to your project.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours