The Tube Chamfering Machine Buying Guide for taking Your Parts Finishing to the Next Level

Enhance your parts finishing by choosing the right tube chamfering machine the tool to help you achieve the best quality you need. This buying guide will help you to make the correct choice of the necessary machines that best fit your requirements. The appropriate tool for chamfering will turn the partnering enhancing efficacy into the one determining stability.

Identify major criteria that can influence the choice and improve your parts finishing to the next level in terms of budget, features, or performance. In this article, we are going to discuss various ways, through which you can decide about the right chamfering machine.

Introduction

Importance of Chamfering for Tube and Pipe Fabrication

- Safety:Chamfering removes the sharp edges and one can avoid cases whereby an individual handling the products will be prickled hence leading to injuries while at the same time fixing them.

- Fit and Alignment:It confirms the correct positioning of tubes and pipes when making joints hence is vital for a leak-tight structure.

- Aesthetic and Quality:It improves the appearance of the probably finished new product for the industry satisfying the needs of the customer.

- Ease of Assembly: Clear and at an angle make assembly and welding easier in the sense that it is easy to work on.

How a Specialized Tube Chamfering Machine Can Elevate Your Parts Finishing?

- Precision and Consistency: It has the advantage of giving true and equally sized chamfersthat can help to eliminate mistakes and therefore eliminate the need to refashion.

- Increased Efficiency: Faster and efficient in chamfering hence reducing time and labor to get the best results.

- Versatility: Operating capability of the material and size of the tube and pipe, which is convenient for the diverse application field.

- Cost-Effectiveness: Increases productivity and efficiency of the process and decreases the costs for labor and amount of liter material used.

1. Understanding Tube Chamfering Machines

Definition and Purpose of Tube Chamfering

- Definition: Chamfering of the tubes includes making edges or ends of the tubes and pipes bevel to eliminate sharp edges and to make the material ready for additional operations.

- Purpose: The primary reason for chamfering is that it is considered safe, and it enables a correct and accurate joint, as well as giving the final product an aesthetic and functional value.

Key Features and Mechanisms of a Tube Chamfering Machine

- Cutting Mechanism: Uses knives or drills to sharpen a specific bevel on the edges of the tube.

- Adjustment Capabilities: Has an adjustable control circle for chamfering angle, depth, and the outer diameter of the tubes as the need arises.

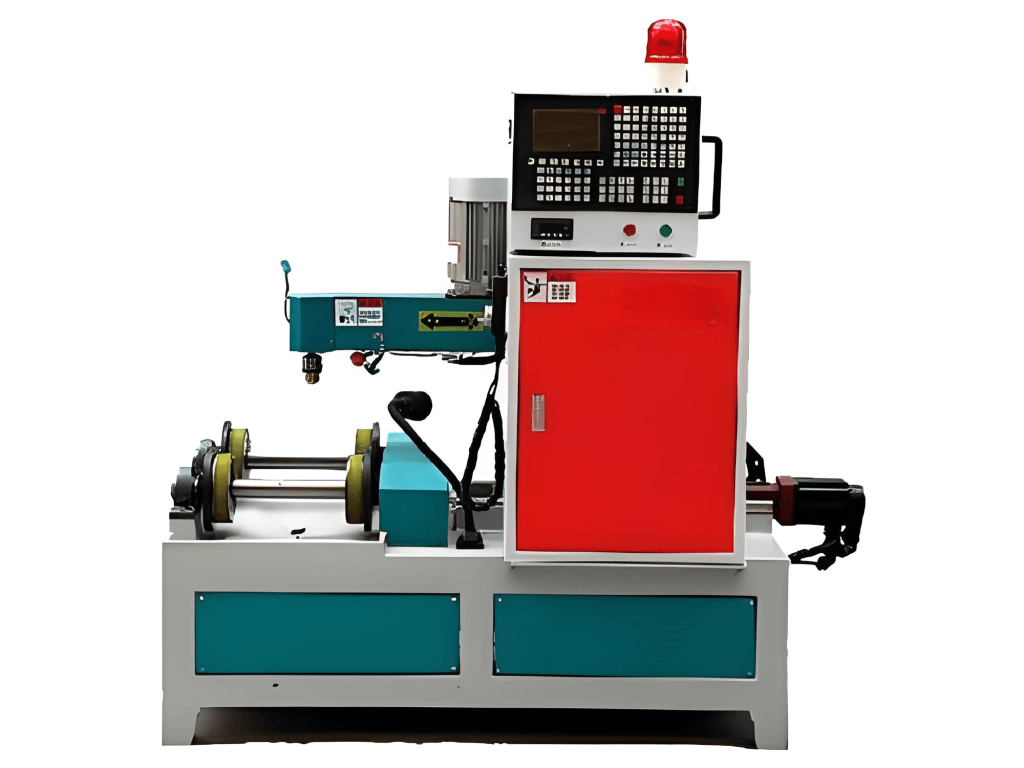

- Automation: This may encompass bypassing feeding and cutting operations so that they can be mechanized hence reducing manpower.

- Material Handling: Provided with clamps or fixtures that are used in holding the tubes while the chamfering is being done.

- Safety Features: Has incorporated guards and emergency stop functions aimed at protecting the operator.

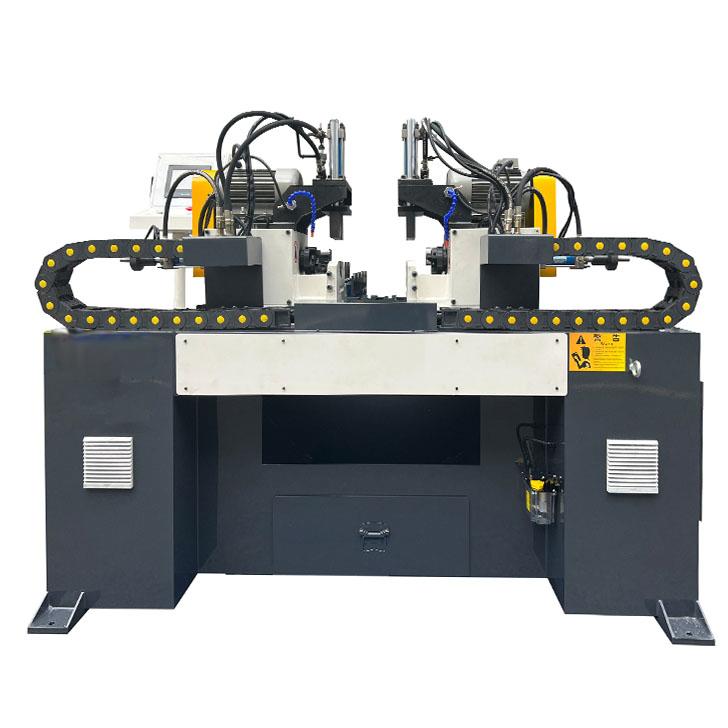

Types of Tube Chamfering Machines

- Manual Chamfering Machines: Mainly manual, can be used for home production or limited production with low frequency. Cuts the expenses down but can be more time-consuming and demands precise work with the materials.

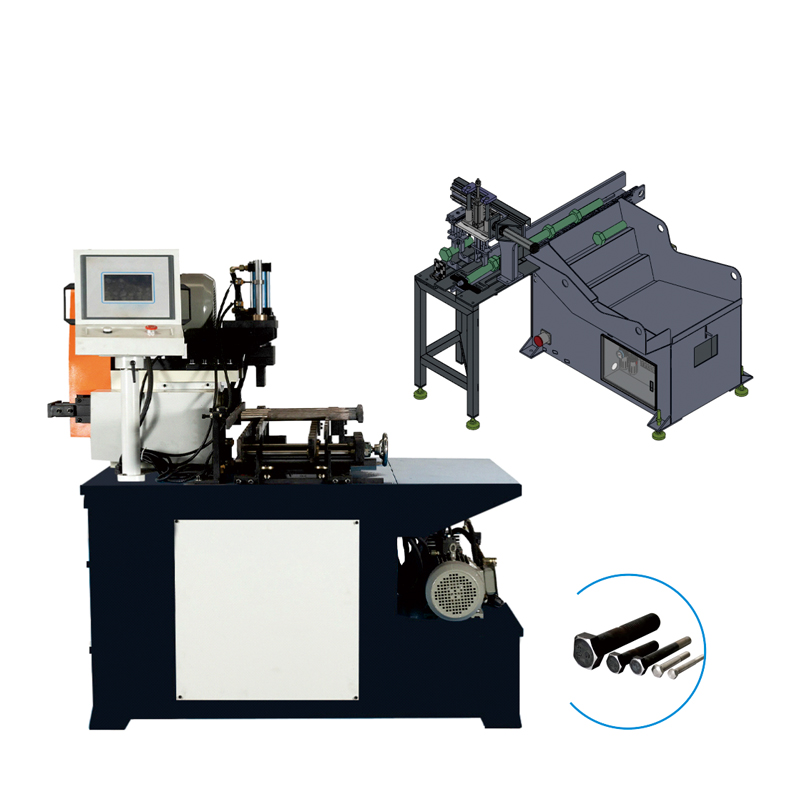

- Semi-Automatic Chamfering Machines: Interlinks the use of manual loading of parts with automated chamfering operations. Which at the same time introduces an acceptable trade-off between cost and utility?

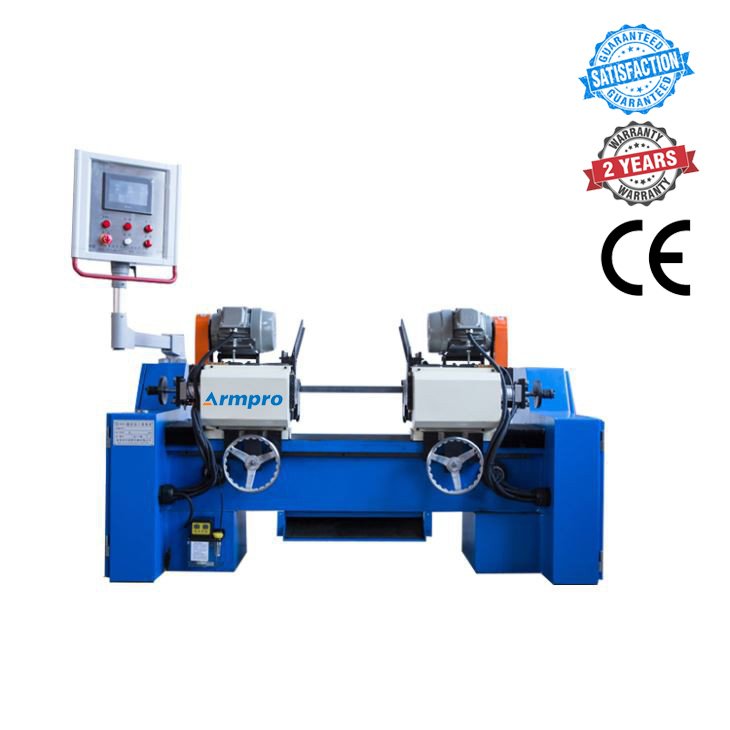

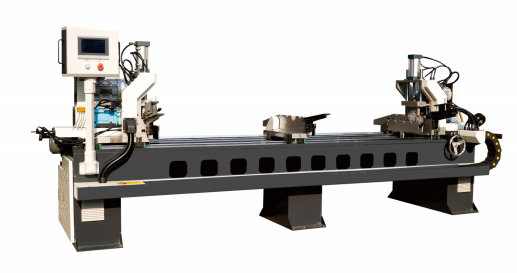

- CNC Chamfering Machines: Fully automated by CNC to have high accuracy, parallelness, and production rate. Suitable for use in large-scale or highly accurate work.

- Portable Chamfering Machines: Portable, primarily for those tasks that will be done on the site or in the field.

Factors That Differentiate Tube Chamfering Machine Models

- Precision and Accuracy: The degree to which a machine can achieve exact chamfering dimensions and angles.

- Speed and Efficiency: The rate at which the machine can process tubes and the level of automation involved.

- Versatility: The ability to handle different tube sizes, materials, and chamfering requirements.

- Ease of Use: User-friendly interfaces, ease of adjustments, and maintenance requirements.

- Cost and Value: Initial investment, operating costs, and overall value considering the machine’s capabilities and lifespan.

- Brand and Reliability: Manufacturer reputation, durability, and availability of customer support and spare parts.

2. Assessing Your Tube Chamfering Requirements

Evaluating Your Current Tube and Pipe Finishing Challenges

- Current Issues:Find areas of concern that are evident in your product, including; burrs, sharp edges, poor fitting or finish, or lack of uniformity.

- Production Volume: You should then assess the number with which tubes you deal to understand the capacity that you require.

- Material Types: Think about what you are going to chamfer, for instance, you may need to chamfer stainless, aluminum, or PVC materialwhich will need different chamfering tools or possibly settings.

- Precision Requirements: Determine whether your applications will need great accuracy, and/or whether the components are for industries that demand high accuracy such as aerospace or medical industries.

- Labor and Time Constraints: Consider the level of input that requires actual physical interaction in the present process and the time required to perform the chamfering tasks.

Identifying the Optimal Chamfer Size, Angle, and Edge Quality for Your Applications

- Chamfer Size: Determine from the tube diameter and Wall thickness what chamfer size you should be using. Where the tubes are relatively narrow, then the chamfers employed may need to be very small compared to when the tubes used are larger, and correspondingly, larger bevels may be necessary.

- Chamfer Angle: Determine the chamfer angleto use, which can be the best for the best fit and jointing for the specific application areas. Typically, it varies between 15 and 45 degrees, considering the industry and the application of the building.

- Edge Quality: Choose the precision of the edge that is needed, burr or lack of it to the finish. An application in the field of micromechanics may demand the surface finish as flawless as possible, but a routine application means may have acceptable tiny surface defects.

- Application-Specific Needs: There will always be special needs for such applications of your products which might require beveled edges for welding, threading, or any other assembly procession.

- Future Growth: Consider future enlargement or alteration of your production which may in turn change the necessitated chamfering. Thus, it is preferable to choose a machine that can respond effectively to different demands to avoid the problem.

3. Essential Features of Tube Chamfering Machines

Clamping and Holding Mechanisms for Various Tube Diameters

- Versatile Clamping Systems: Machinesshould feature adaptable clamping mechanisms to securely hold tubes of different diameters, ensuring stability during the chamfering process.

- Quick-Change Clamps: Quick-change clamping systems allow for fast and easy adjustments between different tube sizes, improving workflow efficiency.

- Non-Marring Clamps: Clamps are designed to avoid damaging the surface of the tube, especially important for finished or delicate materials.

- Rotational Holding: Some machines include rotational holding features to ensure even chamfering around the entire circumference of the tube.

Adjustable Chamfer Angle, Depth, and Width Controls

- Angle Adjustment:Ideally, the use of machines should enable the chamfer angle setting to some certain degree that is, 15° – 45° or more according to the need.

- Depth Control: There is also the flexibility of depth control on the chamfering job to make sure that the chamfer made is as per the design and the extent of the chamfer as required.

- Width Control: In the case of tubes of unequal thickness, any alteration of the chamfer width is also important to achieve the required width of the forming edge.

- Tool Change Flexibility: Chamfering machines that accommodate change of the cutting tools will be able to meet the many requirements required within the different materials making productivity possible.

Thus, focusing on such features will make it possible to receive the best tube chamfering machine, which will be equipped with maximal possibilities to meet the variety of finishing needs and become an essential tool for improving production effectiveness and the quality of the final product.

4. Tube Chamfering Machine Buying Considerations

Evaluating Manufacturer Reputation and After-Sales Support

- Brand Reputation: Often, it proves beneficial to investigate the manufacturer’s background and their position in the market. There are many chamfering machines in the market; look for reputable brands that have quality products that do not break down easily.

- Customer Reviews and Testimonials: There should be cross-verification of the product’s quality by checking the reviews and testimonials from other users on how purport to gauge customer satisfaction and therefore real-world performance.

- Warranty and Guarantee: Make sure the manufacturer provides a good warranty and a money-back guarantee to cover the equipment’s cost.

- Training and Installation Services: Some manufacturers offer training and or installation services and these are useful in guaranteeing the right setting and use of the equipment.

- Availability of Spare Parts: Ensure that the spare parts for the equipment you are using are easily accessible and that the manufacturer has given a simple procedure on how to order the spare parts.

Assessing Your Budget and Cost of Ownership

- Initial Purchase Price: This should involve the purchase price of the machine about your enterprise’s ability to finance the machine and the operational needs of your business.

- Operating Costs: Consider its power consumption and expenditure on its maintenance as well as the expenditure on accessories that is the cutting tools and clamps.

- Lifespan and Durability: Aim at having a long-lasting machine to reduce the regularity of having to make new purchases which would sum up to more than the cost of having to purchase a machine with a very long life cycle.

- Financing Options: Look at different ways in which an individual might make the payment to have the product by taking a look at the available options for financing from the manufacturer or a third party.

- Total Cost of Ownership (TCO): Accumulate all expenses linked to the use of the machine in the expected span of its use to understand the total expense you’re going to make.

Thinking through all these factors provides you with a good chance of creating a balance between the costs, quality, and support that is provided so that you can get the best tube chamfering machine for your purposes.

Conclusion

To sum up, the choice of the right tube chamfering machine is the key to guaranteeing the quality of the finished parts. In this way, by hearing about particular types of machines, budgets, and certain application requirements, it is possible to achieve maximum performance and even raise productivity.

It is always best to go for the best when it comes to tools like the chamfering machine since the performance, quality, and appearance of your parts will significantly benefit from it. When evaluating and making the right choices you will be able to achieve the finishing desired with your productions.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024