Worried about the price? How to choose the most suitable chamfering machine?

Are you worried about the price? It was established that determining the suitable chamfering machine is not just a mere selection of the cheaper machine. This involves looking into the functionalities of the machine, what it can do, and how suitable it is to the intended application.

This is because you have been able to consider factors that can help you get a chamfering machine that will give you value for your money and at the same time do the job as expected. Below is an outline for the guide to enlighten you.

Introduction

The Importance of Chamfering in Metalworking

Chamfering has great importance in metal working as it applies beveled edges on a workpiece. It also increases aesthetics since edges that are sharp and may lead to injuries are eliminated by this process. Additionally, chamfering enables easy joining of the parts hence reducing stress concentrations and offering a near-perfect fit of the components.

Budget as a Key Consideration When Purchasing a Chamfering Machine

Various things are considered when selecting a chamfering machine and one of them is cost. Even though high-quality machines may be slightly costly, it is worth considering your options in a bid to acquire the most effective, durable, and meet the required cost. This consideration is done carefully, thus guaranteeing that you get the most desirable value out of your money and at the same time meet your operating requirements.

Thesis: This Article Will Help You Find the Most Suitable Chamfering Machine Within Your Budget

In this article, you will be assisted to choose the suitable chamfering machine that falls within your range of budget. Let us describe the primary considerations which are the machine type, basic components, and, finally, the affordable solution to each other to make your choice right.

1. Basics of Chamfering Machines

The Purpose and Working Principle of Chamfering Machines

Chamfering machines also find application in metalworking processes and are made use of to produce chamfer edges on metal workpieces. Chamfering can be used solely for aesthetic value, for safety measures, and also to ensure that assembling becomes easier to undertake.

Purpose:

- Edge Enhancement: This operation adds a sloping level to the anchored edge of a component and thus a beveled edge is good for the face of metal components. Chamfering is important in several applications in industry and business where the quality of the finish is of paramount importance.

- Safety Improvement: Wares, especially those molded from metal, have edges that are conterminous that are lethal. Chamfering eliminates these edges to minimize the ability of people to get injured while handling as well as using the products.

Working Principle:

Chamfering machines work through the use of a tool that cuts a steep face on a workpiece to give a slope on the edges. This process involves:

Tooling: Depending on the finish and type of the machine used, it employs plates made up of rotating blades, cutting wheels, cutters, knives, and grinders.

Machine Types:

- Manual Chamfering Machines: These are manually operated and are best used for accuracy work and confined range work.

- Semi-Automatic Machines: These offer semi-automated operations – a set of manual and automated features, which enhance the rates of work and control.

- Fully Automatic Machines: Specifically, they are machine tools widely used for the chamfering task in mass production to reduce human intervention and produce uniform results.

The Tradeoff Between Price and Performance

Pricing of the chamfering machines is another factor that should be considered to arrive at the appropriate one hence the need to look at the price and quality. It involves both the cost and value creation at the point of entry into the market and into the long-term future.

- Higher-Priced Machines:

- Features: Some of the features that are usually hard to find in cheap machines include settings, accuracy, and higher durability of the machines. These features enhance the trim and chamfer operation to be applied for heavy work and large-scale production.

- Performance:Operations are better and more uniformly performed with high price tags attached to those models. It is designed for heavy-duty, as such, it is more reliable and will have a longer life span.

- Durability: Premium machines usually are built more solid and do not require adjustments as often and for this reason, even though they might be initially more expensive, those machines provide better cost recovery in the long run.

- Budget-Friendly Machines:

- Cost:They cost less than some of the most sophisticated machines, thus you find that these machines are ideal for small businesses or those firms that have limited capital investment.

- Performance:They may not possess some of the features and accuracy which for the more complicated work or high work rates may not work optimally.

- Maintenance: Less expensive choices may be more demanding or have a lower reliability indicating that aspect despite having lower initial outgoings may turn out to cost more in the long run.

To achieve this, the following factors need to be put into consideration to ensure that one obtains a chamfering machine that which he wants and which is within his ability to afford.

2. Assessing Your Chamfering Needs

Pain Points in Your Current Manufacturing Process

- If your current process produces uneven or substandard levels, you may need a machine that offers more precise control and consistent results.

- If chamferingis causing bottlenecks, look for a machine that enhances efficiency and speed, potentially through automation.

- Machines that frequently break down can disrupt production. Consider a machine known for its reliability and lower maintenance needs.

- If your current machine is difficult to operate, a more user-friendly model with simpler controls could reduce training time and errors.

- Manual chamfering may be labor-intensive. An automated or semi-automated machine can reduce labor costs and improve productivity.

Production Volume and Workpiece Dimensions

- High Production Volume: For such a business you should select a machine that offers high speeds and is reliable to enable high quantity production.

- Varied Workpiece Sizes:Regarding the size and shape of the workpieces, embracing a machine with the ability to clamp and set various shapes will suffice.

- Workpiece Thickness: Make sure the thickness of what you are working on can be handled by the machine. Some devices are appropriate for slimmer or thicker materials.

- Production Flexibility: If you are in an operation where you may require a variety of chamfering jobs that may require different settings or attachments on the machine then look for a machine that has some level of flexibilityin its settings.

3. Key Features of Budget-Friendly Chamfering Machines

Flexible Clamping and Adjustment Mechanisms

- Adjustable Clamping Systems: Equipment having variable clamping facilities can effectively grip a variety of sizes and forms of workpieces thus enabling easy changeover and a whole range of operations to be performed.

- Variable Angle Adjustments: Ensure that you find machines that will also have the ability to make changes on the chamfering anglesbecause this will give you various bevels for the different jobs that you will be handling.

- Tool Height and Depth Adjustments: With specific capabilities that allow for precise control of the tool height as well as the depth of the chamfer, it is easy to obtain repetitive results of the operation across the various work pieces.

Simple and User-Friendly Operation Interface

- Intuitive Controls:Introduction of controls on the interface that are easy to use and have simple designs also ensure that the operators can learn how to use the machines in the shortest time possible therefore reducing errors.

- Clear Display: An advantage of this design is that when used, operational information and settings are easily communicated to the user hence the usability in monitoring the machine’s performance.

- Efficient Setup: Any machines that allow the user to create chamfering programseasily or to allow setup of tools to be chamfered easier reduces time significantly.

Reliable Performance and Durability

- Sturdy Construction: Cheap machines should not be made with cheap materials that make them easily damaged or develop faults due to wear and tear.

- Consistent Output: There are two important criteria about the chamfering process that define the quality of the chamfering machines; There are durability: looking for machines that reliably produce high-quality chamfers without requiring alterations or repeated rework.

- Low Maintenance Needs: Machines that do not require much attention frequently to be maintained and whose parts are easily accessible for cleaning and check-ups are useful in controlling the operating costs while enhancing long-term operation.

4. Recommendations for Purchasing a Budget-Friendly Chamfering Machine

Comparing different brands and models

- Research Brands and Models: Researchshould be done on different brands and models to compare which among them has the most advantageous and economical features. Choose manufacturers that have good and tested products, which are preferred by customers.

- Read Reviews and Testimonials: Read the internet testimonials, online forums, and customer reviews to make sure that the chosen chamfering machine works fine and is good enough to be purchased. The comment section shared by people can hold significant insights concerning a machine’s performance in the real world.

- Request Demonstrations: Wherever possible one should ask for one to be given a working demonstration or perhaps get to work with one for some time. This can also assist you in determining the simplicity of using the products, their effectiveness, and if they are ideal for your requirements.

Balancing Initial Investment and Long-Term Operating Costs

- Evaluate Initial Cost: Chamfering machinecost revolves around the initial cost for the particular machine or tool, it also includes other costs such as installation cost and training cost if there are any. You can easily compare the prices of the models; therefore, ensure that you settle for a model that fits your financial capacity.

- Consider Efficiency and Productivity: When machines that are efficient in producing the products are expensive at the initial stage, they will take less time to manufacture the standard number of products hence increasing the rate of production.Assess how this particular show by the machine will influence the general operations in the company or business establishment.

- Calculate Total Cost of Ownership: Therefore, there is the need to look at the total acquisition cost and operating cost to make a wise decision. This holistic view will aid you in choosing a machine that offers the best value proposition over the machine’s life cycle.

Conclusion

Choosing affordable chamfering equipment from the market is important. First, understanding chamfering and machine operation will let the user determine which factors are important. Easy clamping and adjustment, instrument functioning, and reliability are always important, even for cheap instruments.

Therefore, you can choose a chamfering machine that matches your performance goals and fits your budget. It is vital to assess your average throughput, workpiece dimensions, and challenges applying improvement measures. Using a suitable machine will boost metalworking efficiency, quality, and value.

Don't forget to share this post!

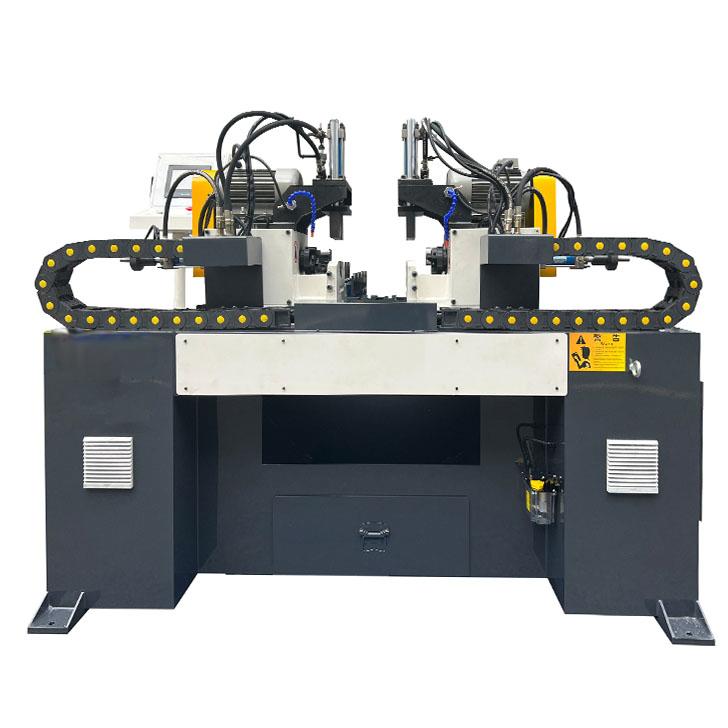

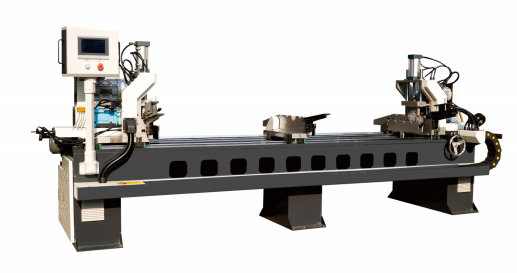

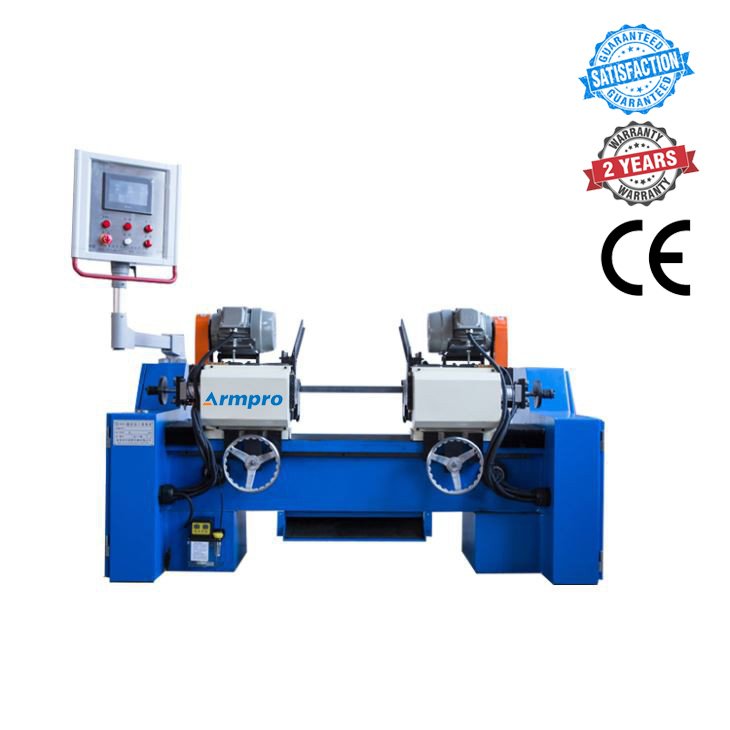

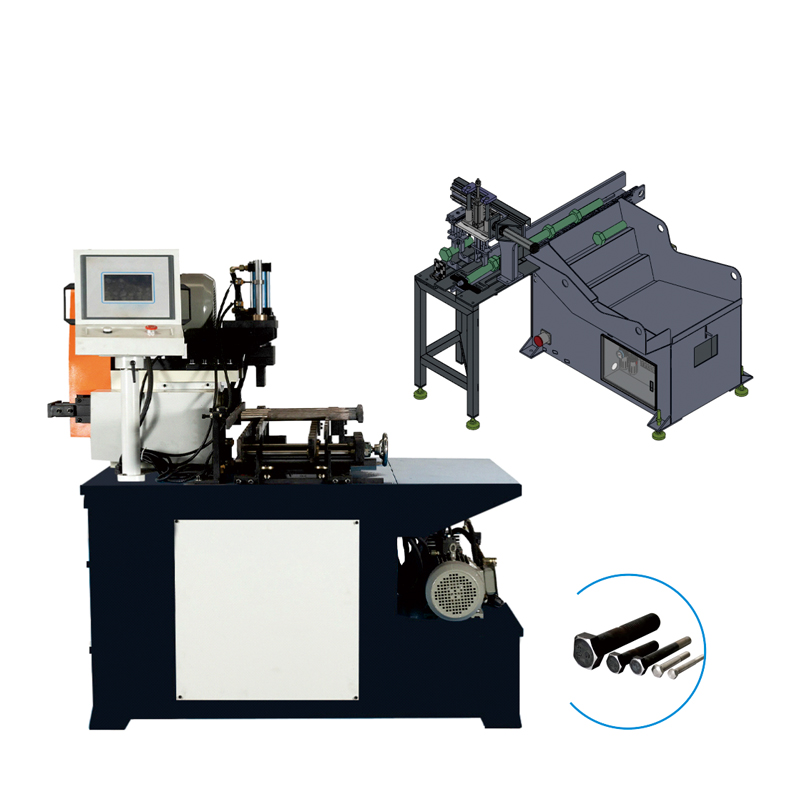

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024