6516V Bench Tapping Machine

Armpro 6516V series multifunctional bench tapping machine resort to high precision, both adding oil and blowing scraps when tapping could help to keep the screw taps clean, which could highly increase the tapping accuracy. The advantage of high tapping efficiency can spare manual work for adding oil and blowing scraps.

Screen protector cover

Customized items

Fast speed tapping capacity

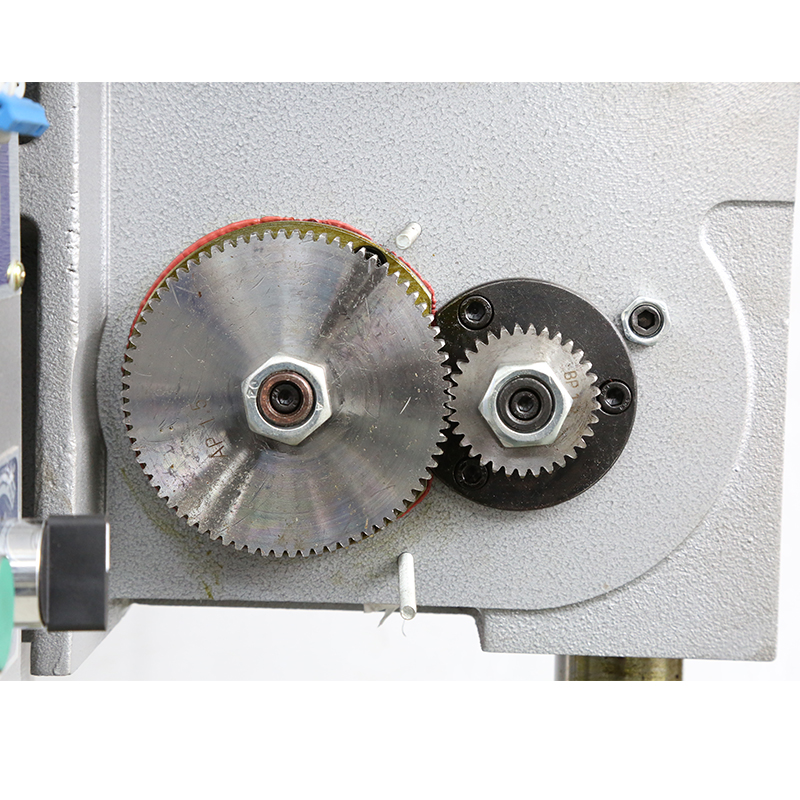

6516 Gear Type Automatic Tapping Machine

Gear Type Fully Automatic Tapping Machine

Characters:

The machine’s feeding is driving by the change gear,the feeding setup has the spring which eliminate clearance,it can extrusion the tap so it can make the hole’s precision and purgation to the ideal requirement.

The depth of tapping can be adjusted by the depth know, it is very precise.

The machine adopt fast-changing tapping chuck, the tap is more easily to change, and clamp firmly.

Main drive and feeding system have the rub clutches respectively, it can out off drive chain automatic when if suffered some balk, it can prevent the break.

there is an urgent bottom at the most convenienct place.

one the cover of exchanging gear there has a safety device, it can assure safety of the operator.

In order to produce in bulk, but machine’s electrical system can achieved the spindle feeding auto-circulation and spot-start singlecirculation.

the machine adopt one srew distance per circle, feeding and withdrawing automatic at synchronization so it can tapping perfectible screw thread on kinds of usual material.

Easy to change the thread-pitch gear and easy to operate as well.

The gear-drive thread pitch reduces wear to a minimum.

Max Tapping capacity: 16 mm

Spindle travel: 65 mm

Column diameter: Ø70 mm

Distance spindle axis to column generating line: 470mm

Base size: 340 x 360 mm

Spindle speed 60HZ: 260 ~ 590 mm (3 steps)

Spindle taper: MT2

Spindle motor – 1.5KW (4P)

Gross weight: 310kgs