6532V Bench Tapping Machine

Armpro easy operation 6532V series bench tapping machine give top priority to improving tapping working life, blowing scraps when pull back so as to keep the lubrication state of tapping. At the same time, the cooling function could help to keep screw taps in a low temperature to protect the equipment from high temperature burning.

Large tapping air pressure

Wide application

High efficiency production

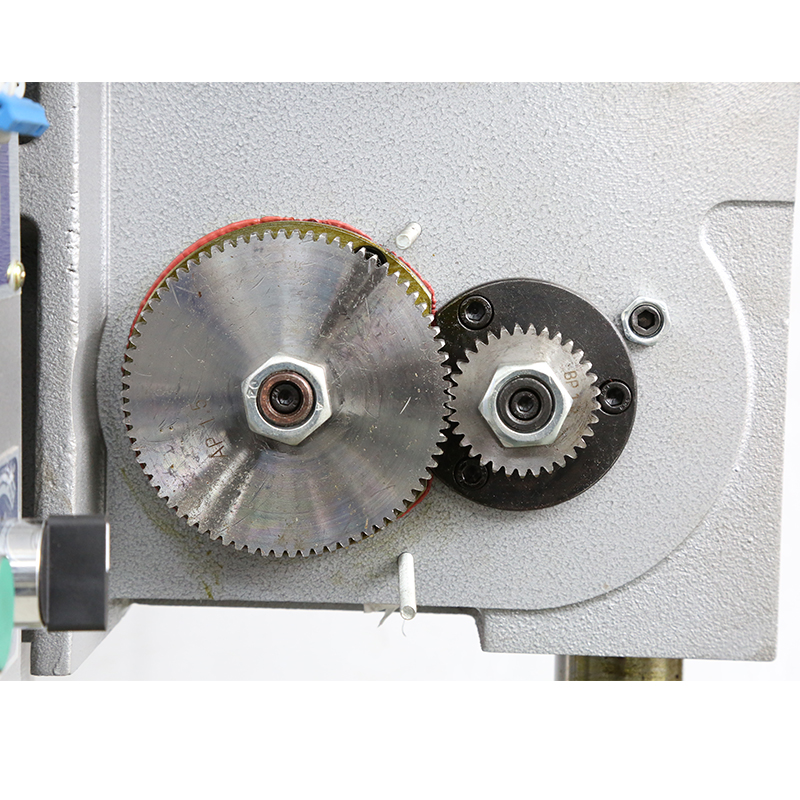

6532 Gear Type Automatic Tapping Machine

Gear Type Fully Automatic Tapping Machine

Characters:

The machine’s feeding is driving by the change gear,the feeding setup has the spring which eliminate clearance,it can extrusion the tap so it can make the hole’s precision and purgation to the ideal requirement.

The depth of tapping can be adjusted by the depth know, it is very precise.

The machine adopt fast-changing tapping chuck, the tap is more easily to change, and clamp firmly.

Main drive and feeding system have the rub clutches respectively, it can out off drive chain automatic when if suffered some balk, it can prevent the break.

there is an urgent bottom at the most convenienct place.

one the cover of exchanging gear there has a safety device, it can assure safety of the operator.

In order to produce in bulk, but machine’s electrical system can achieved the spindle feeding auto-circulation and spot-start singlecirculation.

the machine adopt one srew distance per circle, feeding and withdrawing automatic at synchronization so it can tapping perfectible screw thread on kinds of usual material.

Easy to change the thread-pitch gear and easy to operate as well.

The gear-drive thread pitch reduces wear to a minimum.

Max Tapping capacity: 32 mm

Spindle travel: 65 mm

Column diameter: Ø70 mm

Distance spindle axis to column generating line: 470mm

Base size: 340 x 360 mm

Spindle speed 60HZ: 260 ~ 590 mm (3 steps)

Spindle taper: MT2

Spindle motor – 1.5KW (4P)

Gross weight: 310kgs

APPLICATION FIELD

- Moulds & Dies

- automotive industry

- Auxiliary in CNC machines

- Plate industry

- Mechanization industry

- Aerospace

- Consumer electronics

- Medical industry

- Defense industry

- Oil & gas industry

PRODUCT ADVANTAGES

1. Optical Fiber Laser, environment friendly, easy maintenance.

2. Life of the laser can be up to 100000 hours.

3. Runs without consumable spare parts, no need maintenance, great for continuous working.

4. Good touch interface and powerful control system.

5. Advanced digital high speed scanning galvanometer.

6. Small volume, quick speed, good stability

7. Multifunctional marking software

PCX, DXF, support PLT, BMP, SHX, TTF font can be used directly

8. Software running on the WINDOWS platform, English interface, compatible with Coreldraw, AutoCAD, software such as Photoshop file

TECHNICAL PARAMETERS

Max Tapping capacity: 8 mm

Spindle travel: 45 mm

Column diameter: Ø52 mm

Distance spindle axis to column generating line: 185mm

Base size: 230 x 225 mm

Spindle speed 60HZ: 420 ~ 1340 mm (3 steps)

Spindle taper: B16

Spindle motor – 0.75 (4P)

Gross weight: 145kgs