Discover the Leading 10 Gear Chamfering Machine Manufacturers in the USA

Introduction

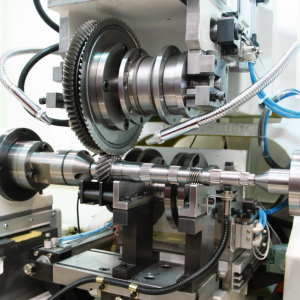

CNC Gear Chamfering is considered one of the significant processes in the manufacturing industry to refine the gears in some manner such as reducing the tendency of the gears to get worn out quickly, reducing noise level during the operation, and smooth running of gears.

The demand for gear chamfering machines is higher than in the past due to a need to enhance industry precision and productivity. This article aims to find out the top 10 gear chamfering machine manufacturers in the USA to understand the best companies that design and implement high-quality, cost-effective, innovative, and easy-to-use gear chamfering machines.

1.The Importance of Gear Chamfering

Definition:

Reducing the thickness of the gear tooth profile usually concentrated at the peak of each tooth is called gear chamfering, profiles that have sharp edges and burrs. This step is very important in producing gears since the process enhances the improvement of the gears’ engagement and assembly in mechanical structures.

In addition to completing the engineers’ aesthetic vision, chamfering also plays a part in improving the quality, performance, and service life of the gears.

Benefits:

- Improved Gear Performance:

Through chamfering, the contact surfaces of the gear's performance are modified such that they have more accurate and closer fits; they therefore produce minimum noise and vibration during operation. As a result, it also demands the correct fit of gear teeth that will improve the efficiency of the transmission.

- Reduced Wear and Tear:

Gear chamfering reduces stress concentration that may cause gear tooth unbearable hence the significance of gear chamfering in reducing stress concentrations. This minimizes contact and reduces the heat generated thus minimizing the chance of early wear and tear.

- Enhanced Durability:

Gears of chamfered form as compared to plain form are less vulnerable to be affected and thus enjoy longer life in operation. The process enables increased time between the maintenance and increases the reliability of the gear systems.

2.Criteria for Selecting a Gear Chamfering Machine Manufacturer

· Quality and Precision:

When it comes to selecting a manufacturer of gear chamfering machines, it is critical to focus on quality and precision. When chamfering of gears is done by high-quality machines, this ensures that the engagement of two gears and other cubicles are smooth and will offer long-lasting gears.

· Technological Innovation

In the case of chamfering machines, technological innovations are responsible for the productivity of the machines. Those modern manufacturers that invest in new technologies like robotic automation, CNC controls and better cutting tools provide machines that are not only more effective but also more precise.

· Customer Support

Well-established customer support and credible after-sales service are some of the critical factors to consider when choosing a gear chamfering machine manufacturer. Such support means that the users can fix problems themselves, with little or no disruption to services.

For example, Proactive manufacturers help to train, troubleshoot, and provide easily accessible spare parts enabling a manufacturer to enhance the use value and longevity of the equipment.

· Reputation and Reviews

A manufacturer’s reputation coupled with the reviews from customers indicates the reliability and performance of the machines. Recommendations from other buyers mean that prior quality product delivery and reliable service have always been their hallmarks. Assessment of a manufacturer assists a buyer in acquiring appropriate information and then identifying the manufacturer who enjoys a good reputation.

3.Top 10 Gear Chamfering Machine Manufacturers in the USA

1. Gleason Corporation

Overview: Gleason Corporation was established in 1865 and has been in Gear Technology right from its inception. The company has products suitable for different gear manufacturing processes such as chamfering.

Key Products: Gleason’s big brands of gear chamfering machines are 300GMSL and 100C because of their accuracy and adaptability.

Strengths: Many customers know Gleason for advanced technological innovations, for example, for a highly developed level of automation and sponsoring. They also have excellent customer support to top it all up.

2. Klingelnberg America

Overview: Founded in 2010, as a part of the Klingelnberg Group, Klingelnberg America offers over 100 years of gear manufacturing technology serving multiple markets across the United States.

Key Products: They have the Chamfer Cut and Closed Loop quality Chamfering machines which they claim are the best chamfering machines for the best chamfering jobs.

Strengths: There are more known facts about Klingelnberg; they are esteemed for the high precision and sound quality of their machines as well as for their research efforts.

3. Liebherr Gear Technology

Overview: Liebherr Gear Technology is not only a division of the Liebherr Group, but also a key company in the manufacture of gear products, specializing in the application of new technologies.

Key Products: The latest chamfering machines are the Chamfer Cut series which are considered technologically advanced.

Strengths: There is a testament to the fact that Liebherr has mastered the art of incorporating state-of-the-art technologies into the machines to hike up performance and efficiency.

4. Star SU LLC

Overview: Star SU LLC offers a wide range of gear manufacturing solutions has its presence in the United States and focuses mainly on machining solutions.

Key Products: The range of chamfering machines incorporates high-accuracy machines suitable for a broad area of applications used in the gear industry.

Strengths: Star SU enjoys a great reputation in the industry and, therefore, the constant ability to create new gear machining solutions.

5. Koepfer America

Overview: Koepfer America Company is one of the significant market players in the gear manufacturing Industry offering different products in cutting and chamfering gear products.

Key Products: Their chamfering machines are known for their precision which makes them appropriate for producing highly complex gears.

Strengths: Koepfer America is renowned for its accurate machines and embracing customer support, offering good service as well as training.

6. ANCA Inc.

Overview: ANCA Inc. has specialized in the production of high-precision CNC machines, with solutions for gear chamfering.

Key Products: Their chamfering solutions have integrated modern features of computer numerically controlled technological innovations to enhance accuracy.

Strengths: ANCA is known for technology and accuracy in precision engineering making their machines effective.

7. Höfler America

Overview: Höfler America is a member of Klingelnberg Group that specializes in providing quality gear manufacturing machines; Chamfering solution is among its offers.

Key Products: Their quality chamfering machines are equipped to provide better quality and are versatile that meet the requirements in gear manufacturing.

Strengths: Thus Höfler has been applauded for offering Quality or tech aids, to give dependable solutions.

8. Samputensili

Overview: Samputensili is a well-known producer of gear manufacturing equipment, which aims to create progressive and accurate tools.

Key Products: Among other offerings of their chamfering machine are those with high-end features to enable high precision in gear cutting.

Strengths: The machinery used by Samputensili is accurate, thus increasing the quality and strength of the gears made.

9. Reishauer Corporation

Overview: The company is Reishauer Corporation which is an industry participant manufacturing and offering gear grinding and chamfering machines.

Key Products: These chamfering machines incorporate new technological innovations to provide the right degree of chamfering.

Strengths: Reishauer has always been popular for being innovative technologically especially in the areas of CNC technology and incorporation of excellent client services.

10. EMAG LLC

Overview: EMAG LLC manufactures and supplies a wide range of products and services for the metalworking industry ranging from gear chamfering machines etc. The main reason they influence the market is because of their niche and concentration on issues to do with quality.

Key Products: They have well-illuminating chamfering solutions that are conventionally accurate and include many forms of automation.

Strengths: EMAG is characterized by accurate and high-quality machines and process accuracy that result in consistent gear manufacturing.

4.How to Choose the Right Manufacturer for Your Needs?

· Assess Your Requirements

Consider your particular manufacturing needs including; the sort of gears you make, the number of gears you manufacture, and the amount of automation you wish to incorporate into your venture.

Take time to compare the features of a machine and what you are willing to spend so you get an excellent machine for the amount of money you have to pay.

· Compare Products

Check out what chamfering machines look like, what they offer, and the features of the various models from different product comparison manufacturers. Focus more on accuracies and automation levels, available technologies, and more until you find the appropriate solutions.

· Consider Support and Service

Ensure that the manufacturer provides adequate customer support services in terms of training, maintenance, and repairs among others. Sustaining your operations is very important which can only be achieved if after-sales support is well sorted out.

· Read Reviews and Testimonials

You can conduct research on the internet by searching for various manufacturers and getting an idea of their reputation by reading customers' feedback, testimonials, and reviews. Seek information on features such as product quality, quality of services rendered, and sustained or eventual reliability of goods/services.

Conclusion

Conclusively, this article focused on the top 10 gear-chamfering machine manufacturers in the USA, describing their primary products, advantages, and innovations. Selecting the best manufacturer in the production process is important as an organization will be able to produce high-quality gear with efficiency.

We suggest readers to further analyze these companies and their products for themselves. To make the right decision, minute details can be considered in choosing the right chamfering machine needed in production, thus improving manufacturing success.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024

- Drilling And Tapping Machine:The Complete Buying Guide in 2024