Cold Extrusion vs. CNC Milling: Choosing the Right Gear Chamfering Machine for Your Needs

Introduction:

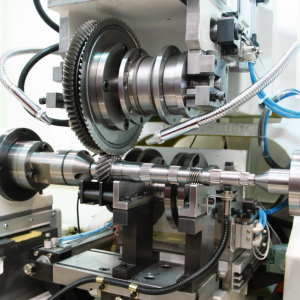

Gear chamfering machine is a very significant process since it helps guarantee that gears have sharp edges and no burr as a way of improving their efficiency and durability. The two methods of chamfering gears include cold extrusion and CNC milling; both of which have advantages.

What is a cold extrusion and what is a CNC milling machine?

Cold extrusion is advantageous in high-volume parts creating production with limited scraps on the other hand CNC milling offers accuracy and adaptability compared to intricate shapes.

This article will draw a view of these kinds of gear chamfering techniques, which includes the suitable application and the merits of the methods, to guide you in selecting a proper process for your manufacturing.

1.Understanding Gear Chamfering machine

What is Gear Chamfering?

Gear Chamfering is the procedure of producing a required edge or angle on the side or at the extremities of gear teeth. This step helps eliminate those leads or sharp points that may be formed due to the gear-cutting or shaping process they are now smoothed out.

Why is Gear Chamfering Crucial in Gear Manufacturing?

Chamfering is an essential step in gear manufacturing for several reasons:

- Reduces Friction:The corners that are cut off in the Chamfered formed part enable better engagement of mesh in some of the gears than when sharp corners are present.

- Prevents Gear Tooth Damage: Chamfering, therefore, reduces the incidence of stress concentration and breakages of the teeth.

- Improves Gear Performance: Improving the contacting surface of the meshing teeth results in improved gear performanceand an increase in the gear’s durability.

2.Overview of Cold Extrusion

Cold Extrusion Process Description

- Cold extrusionis one of the metal forming processes in which the die is brought closer to the metal billet and the process is done at a temperature that is nearly equal to the room temperature.

- It involves the utilization of a hydraulic press to compress the material through a die which forms the metal into the necessary gear contour.

- Design approaches like forward extrusion, backward extrusion, and combined extrusion are applied to achieve different forms of the final product.

Advantages of Cold Extrusion

- Material Savings:Material saving is very efficient in the use of material most of which is used to make the final shape of the product.

- High Production Rates: Cold extrusioncan be scaled for high production rates since the technique is fast and can easily be automated.

- Consistent Quality: Consistent qualityhelps achieve standard measurements, and texture on the side of the gear, thus, fewer distortions between the gears.

Ideal Applications for Cold Extrusion

- Types of Gears: Cold extrusion is used with much success when it comes to manufacturing spur gears, helical gears as well as all kinds of simple shapes of gears.

- High-Volume Production: Gear cutting is best appropriate in situations where there is a need to produce many gears in one go and with similar quality standards, especially in automobile and mechanical manufacturing industries.

- Cost-Sensitive Applications: Cold extrusioncan be used where imprudent material use and slow production rate are unbearable due to the following reasons. The process involves material efficiency and a top production rate.

3.What is a CNC Milling Machine

CNC Milling Process Description

- CNC Millingis a process that allows the use of machines and computer control to cut the periphery for materials to create the needed shape and depth.

- To chamfer gears, CNC milling machines work with special cutting tools that provide logical edge cutting chamfers for gear teeth.

- CNC milling applies to a wide range of chamfering applications and can be used to create any shape or to use different chamfer angles.

Advantages of CNC Milling

- Precision: In the case of CNC Milling, the degree of the complex surface of the gears and the degree of high precisionof the chamfer in the car is very high because of the use of computer control.

- Flexibility: The face gear is a versatile technique that can be used on different kinds of gearing, and geometries and made of materials to create more flexibilityin the mechanism.

- Ability to Handle Complex Geometries: Some of the complex operations that can be done by CNC milling include the chamfering of gears of various forms and shapes of complex geometrieswhich are difficult tasks in conventional practices.

Ideal Applications for CNC Milling

- Types of Gears: CNC millingis also used for machining bevel gears, helical gears, and other gears that have non-standard tooth profiles.

- Low- to Medium-Volume Production: It thrives in conditions that call for high accuracy and differentiation, for instance in aerospace, robot assembly, and equipment niche markets.

- Complex Gear Designs: CNC milling is specifically appropriate when small and differentiated shapes of gears, diverse angles of chamfers, and minute details on the gears are required.

4.Comparing Cold Extrusion and CNC Milling

Cost Efficiency:

- Cold Extrusion: This method is commonly used for large scale, low cost, and less amount of scrap generated, and also, the process is faster. While the initial costs associated with extrusion machinery can be significantly high the operating costs are low for applications that require large-volume output.

- CNC Milling: CNC milling has the flexibility of operations but investing in CNC machines needs significant capital investment and operational expenses are high due to the cost of the tool and energy used. This is less material efficient than cold extrusion, because the operation involves removing material, and hence is wasteful.

Production Speed

- Cold Extrusion:

It is quicker than CNC milling for big batches and enables high production speed rates that are useful for big-quantity production. After the die has been prepared, it is then possible to manufacture gears without having to stop for very long.

- CNC Milling:

CNC milling is also slower than cold extrusion, though it does not generate the same level of tolerances even for high production runs. The speed is a function of the chamfering and gear geometry possibly resulting in changes in manufacturing more quantity in more time.

Quality and Precision

- Cold Extrusion: Makes gears of constant qualityand strength since the metal is exposed to work hardening during production. But it will not be as accurate as with CNC Milling; for instance, when cutting fine chamfers or designing gears.

- CNC Milling: CNC end milling is well known for its high level of precision and ability to produce parts with good surface finishes while providing accurate chamfering through the ability to work with small tolerances. It is employed where there is a high degree of precisionin size and tight tolerance as well as fine chamfering.

Versatility

- Cold Extrusion: Applicable for making simple forms of gears where high numbers of gears are required such as spur and helical gears. It has somewhat restricted flexibility because many die shapes are required for distinct gear shapes and sizes, which can be expensive and take a lot of time to modify.

- CNC Milling:Admits more versatility, as it is capable of accommodating larger quantities of diverse gears, in terms of size and shape, and is made of various types of material. CNC milling is the best when it comes to geometric designs, different angles of chamfers, and unique layouts that have to be unique.

Each of the methods comes with its own benefits: cold extrusion is more cost-effective and suitable for high-speed production while CNC milling has better accuracy, and flexibility and is suitable for intricate gear chamfering in case of more specific gear profiles.

5. Choosing the Right Method for Your Needs

Assessment Criteria:

To help manufacturers decide between cold extrusion and CNC milling, consider the following assessment criteria:

- Production Volume:

Cold Extrusion: Especially tolerant of high volumes of production because they do not cost much and are relatively quick to produce.

CNC Milling: More appropriate for lower to middle scale of production which demands fine and special tolerance to be achieved.

- Gear Complexity:

Cold Extrusion: Applicable to simple gear forms such as spur and helical gears.

CNC Milling: Desirable for designs with tight tolerance levels, a highly polished surface, or perceived shapes, such as gears.

- Cost Considerations:

Cold Extrusion: Easier to compete with other methods, when producing large amounts of material with little leftover.

CNC Milling: Applicable to short runs as the operational cost is outweighed by the ability of the process to offer flexibility as well as accuracy.

- Material Usage:

Cold Extrusion: Provides tangible cost benefits that involve little or no utilization of redundant resources.

CNC Milling: Results in more waste as material is removed but offers a better way to work with varying kinds of material.

- Lead Time:

Cold Extrusion: Possibilities for faster production, especially in case of large orders.

CNC Milling: May take longer time to produce due to the level of detail that may be required in the design and If the amount is large.

Case Studies

- Cold Extrusion Case Study:

Another case study discussed the use of cold extrusion in the production of a high volume of spur gears required in Transmission systems by a big automobile manufacturing firm. This process let the company cut material costs and have equally capable millions of units for testing, which slashed per-part costs.

- CNC Milling Case Study:

CNC milling was also used by an aerospace firm when fabricating high-precision gears for aircraft parts. CNC milling provided application flexibility to produce gear profiles with close tolerances as required by quality standards and offered easy gear designs for adaptation to accommodate unique design specifications of individual orders.

Expert Recommendations

- When to Choose Cold Extrusion: Most specialists in the field of production of gears have indicated that cold extrusion is advisable when manufacturers require products in large quantities and within the shortest time.

They are very useful in car manufacturing and heavy equipment industries in which speed of production and member production are important.

- When to Choose CNC Milling: According to the specialists the best case scenario in which CNC milling is preferable is when the element being produced must be precise and uniquely designed.

CNC milling is suitable for functions that may be more intricate such as those that are found in aerospace, robotics, and specific machinery functions whereby gear forms may be complicated and may need precise chamfering or forms.

Based on the analysis of production requirements and comparisons of gear complexity and cost concerns, manufacturers can determine the appropriate gear chamfering machine technique between cold extrusion and CNC milling.

Conclusion

In the case of comparing cold extrusion and CNC milling of gear chamfering, their merits were discussed which is more economical for cold extrusion than CNC milling includes the speed of production and economical as against the benefits which include the precision and flexibility of the CNC milling.

It is very important to select the right method for improving the production lines. Manufacturers should perform an analysis of their current strategy and wonder if cold extrusion or CNC milling is better for their operations to enhance quality and performance.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024