Steel Sheet Thickness Chart : A Comprehensive Guide

Introduction

Find out the standard sheet size of steel charts by gauges and millimeters equivalents. Quickly compare the thickness of different types of steel, such as stainless, galvanized, and carbon steel.

1. What is the steel sheet thickness chart?

The steel sheet thickness chart or steel sheet size chart is an elaborate table of reference that is used to look at the thickness of various gauge numbers of steel sheets in terms of gauge amount in millimeters or inches.

The steel sheet size chart is necessary for any construction and manufacturing work, along with metalwork and engineering work.

The steel sheet thickness size chart provides a standard set of thickness values, along with information on selecting the right steel sheet for a specific application, such as structural components, vehicle parts, roofs, or manufacturing equipment.

A steel sheet thickness size chart in millimeters enables users to quickly translate gauges to metric sizes, providing an increased level of accuracy and ensuring consistency between projects across borders.

Many different types of steel, such as carbon, zinc-plated, and stainless steel, are often included on these scales; at the identical width level, there may be slight variations in sheet metal thickness.

Using a steel sheet thickness chart or steel sheet size chart will also guarantee the accuracy of the selection of material used, a better match to the design specifications, and prevent any unnecessary, costly errors when making the fabrication or installation of the sheet.

SO, here is a steel sheet gauge thickness chart. We call the sheet metal thickness mm. In this steel sheet gauge thickness chart, I hope you can find something helpful.

| STAINLESS STEEL | ALUMINUM | COPPER | BRASS | ||||||

| GAUGE | THICKNESS | GAUGE THICKNESS 22 0.025" 20 0.032" 18 0.040" 16 0.050" 14 0.064" 12 0.080" 11 0.090" 10 0.100" 9 0.114" 8 0.129"NOTE:There is no official gauge standard for aluminum .250"&thicker is plate |

GAUGE | THICKNESS | GAUGE | THICKNESS | |||

| 28 | 0.015" | 36 | 0.005" | 30 | 0.010" | ||||

| 26 | 0.018" | 31 | 0.011" | 28 | 0.013" | ||||

| 24 0.024" | 28 | 0.014" | 26 | 0.016" | |||||

| 22 0.030" | 27 | 0.016" | 24 | 0.020" | |||||

| 20 | 0.036" | 24 | 0.022" | 22 | 0.025" | ||||

| 18 | 0.048" | 22 | 0.027" | 20 | 0.032" | ||||

| 16 | 0.060" | 21 | 0.032" | 18 | 0.040" | ||||

| 14 | 0.075" | 19 | 0.043" | 16 | 0.050" | ||||

| 12 | 0.105" | 18 | 0.049" | 14 | 0.064" | ||||

| 11 | 0.120" | 16 | 0.065" | 12 | 0.081" | ||||

| 10 | 0.134" | 15 | 0.075" | 11 | 0.090" | ||||

| 8 0.160" | 14 | 0.086" | |||||||

| .125"&thicker is plate | |||||||||

| 7 0.187" | 13 | 0.093" | |||||||

| 12 | 0.108" | ||||||||

| 10 0.125" | |||||||||

| .188"&thicker is plate | |||||||||

| 3/16"&th | icker is plate | ||||||||

2. What materials are used for steel sheets?

The sheets are made of various kinds of steel, which are to be used according to the set of properties and purposes. The most popular materials applied to the steel sheets are:

· Carbon Steel

One of the most frequently used steel sheets is carbon steel. It contains iron and carbon as its main constituents and comes in three forms of low, medium, and high-carbon. There are grades of increasing strength, hardness, and ductility at each grade.

The carbon steel sheets find application in most construction work, auto manufacturing, structural parts, and general fabrication because of their cheapness and versatility.

· Stainless Steel

The stainless-steel sheets are also very resistant to corrosion due to the chromium (usually 10.5 percent and above). Various grades, as well, contain nickel and molybdenum to provide greater strength and resistance to high temperatures.

They find a wide range of applications in the area of food processing equipment, medical equipment, kitchen appliances, and the surrounding marine environment, as they are very clean and tough.

· Galvanized Steel

Galvanized steel sheets refer to carbon steel whose surface is coated with zinc to avoid rust and corrosion.

They work perfectly in outdoor applications and industrial activities, such as roofing, fencing, HVAC systems, and water tanks. The zinc coating greatly contributes to the life of the sheet in areas that are prone to moisture.

· Alloy Steel

Alloy steel is a mixture of carbon steel with other elements, including manganese, nickel, or chromium, to alter mechanical properties, i.e., strength, toughness, and wear resistance. They are applied in aerospace, machinery, and heavy-duty industries.

· Tool Steel

Tool steel sheets are designed to be hard and abrasion-resistant as well as heat-resistant. They are usually applied in cutting tools, molds, and dies.

The selection of each material depends on the requirements of a particular application, the durability, and environmental changes.

3. What is the application of the steel sheet?

Steel sheets are a multipurpose raw material and can be employed in many different industries because of their strength, sturdiness, and ability to be shaped. The most important applications are here:

· Construction and Infrastructure

Steel sheets find application in building structures, roofing and wall panels, reinforcement of structures, and bridges. Specifically, galvanized steel sheets are used because of their properties of corrosion resistance when facing outdoor or industrial conditions.

· Automotive Industry

Car bodies, car chassis, car doors, car roofs, and other parts of the engine require steel sheets in their production. They have the advantage of their strength-to-weight ratio, which makes them assist in improving the performance of vehicles without compromising their safety levels.

· Appliances and Electronics

Steel sheets find application in the production of refrigerators, washing machines, ovens, and air conditioners in the home appliance market. They use stainless steel sheets because they are sleek and rust-resistant as well as tolerant to heat.

· Shipbuilding and Marine Equipment

Ship hulls are constructed with corrosion-resistant steel, as are cargo containers and marine hardware, which must cope with the unfriendly environment of the ocean.

· Furniture and Interior Design

Modern furniture, cabinets, wall partitions, decorative panels, and kitchen appliances are made of steel sheets because of their durability and modern appearance.

· Industrial and Agricultural Equipment

Steel Sheets are employed in the manufacture of machine components, tanks, silos and trailers among other heavy machineries.

The uses of steel sheet are different depending on the type of the material and thickness, hence flexible in all engineering, commercial, and domestic applications.

4. How to choose the right steel sheet?

The type of steel sheet you choose is very important to ensure that your project attains its performance, durability, and price expectations. The following step-by-step guide will assist you in making the appropriate selection of the steel sheet to use:

· Identify the Application

The best way is to start by identifying the end use of the steel. Material properties are different depending on the various applications. For example:

- High-strength sheets are required in structural projects.

- Corrosion resistance is needed for outdoor use.

- Kitchenware or appliances are made advantageous by hygienic and easy-to-wash surfaces.

Knowing the application allows us to narrow down the correct material and thickness.

· Select the Appropriate Material

Various steels have different properties:

- Carbon Steel:Economical and stiff amongst other properties, suited to general fabrication and construction.

- Stainless Steel:Corrosion-resistant, ideal in medical, food-grade, or marine applications.

- Galvanized Steel:Fine rust protection is achieved outdoors as it is Zinc-coated.

- Alloy Steel:Increased strength and hardness for industrial or heavy-duty showcases.

- Tool Steel:It is very hard and heat resistant and is used in precision tools and dies.

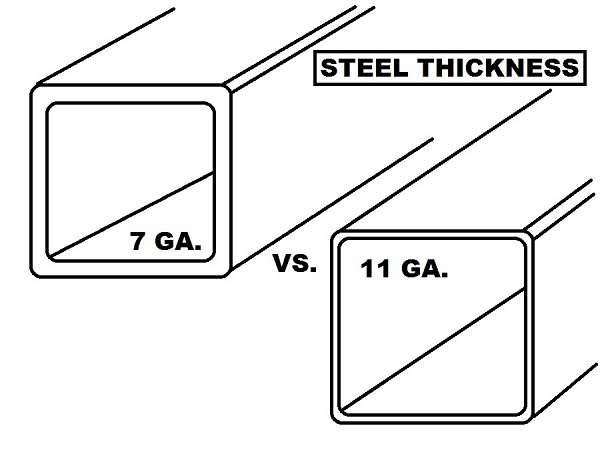

· Check the Steel Sheet Thickness

To select the exact thickness needed in your project, you need to use either a steel sheet thickness chart or a steel sheet thickness size chart in mm. The thicker ease sheets are more resistant and have more strength, but the thinner ease sheets are more flexible and workable.

· Consider Surface Finish and Coatings

Use a physical finish such as polished, brushed, or finish-coated according to aesthetic or environmental requirements. Where corrosion is likely to occur, use galvanized sheets or powder-coated sheets.

· Evaluate Cost and Availability

Make your desired material match your budget, and make sure that the type and size you choose can be easily found among the suppliers.

The type of steel sheet you select will also determine the reliability of your project, its durability, as well as cost-effectiveness.

Conclusion

In conclusion, the steel sheet thickness chart or steel sheet size chart is an excellent source for defining the necessary sheet to use in a project because it gives accurate measurements in gauges and millimeters.

It is important to understand all about the application, type of material, and the sheet metal thickness needed so decisions can be made.

You may want the corrosion resistance, the strength, or the flexibility, but the right sheet can best contribute to its finest presentation.

Combining the thickness size of a steel sheet using a chart in mm will formalize the selection and enhance compatibility with other industries. The ideal results are always achieved when you match the project and the functional, aesthetic, and environmental requirements to your choice.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024