3-Jaw Chuck vs 4-Jaw Chuck,What’s The Difference?

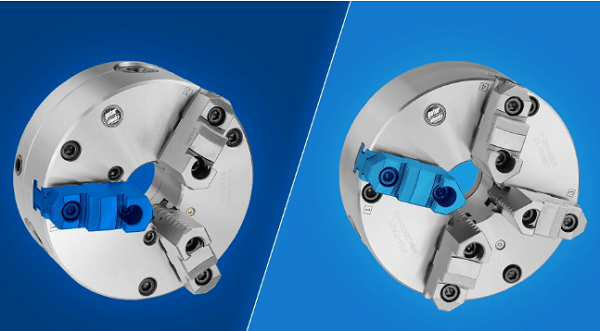

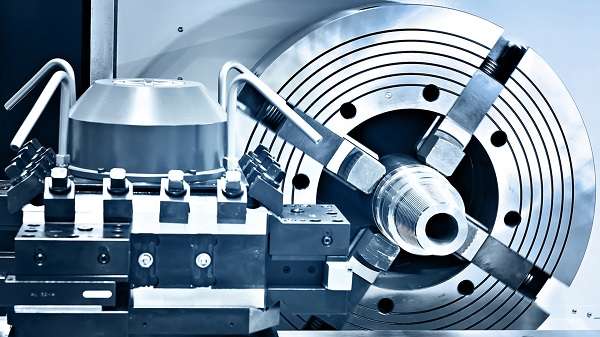

1. What is 3 jaw chuck?

When working with round or triangular components, a 3 jaw chuck is one types of chuck,an essential tool for lathes and CNC machines. The name "3 jaw chuck" comes from the fact that the three jaws work in tandem to produce a single motion.

This makes it automatic to center the workpiece when the chuck is tightened. It is perfect whenever there is a need to perform a fast setup and alignment.

The meaning of the 3 jaw chuck has to do with its simplicity and efficiency; that is, it is designed in such a way that it offers a powerful, even grip, thus benefiting from turning, facing, and drilling. Because the jaws are connected, it is possible to clamp and unclamp parts fast, and in that way, it is more efficient in production settings.

2. 3 jaw chuck application

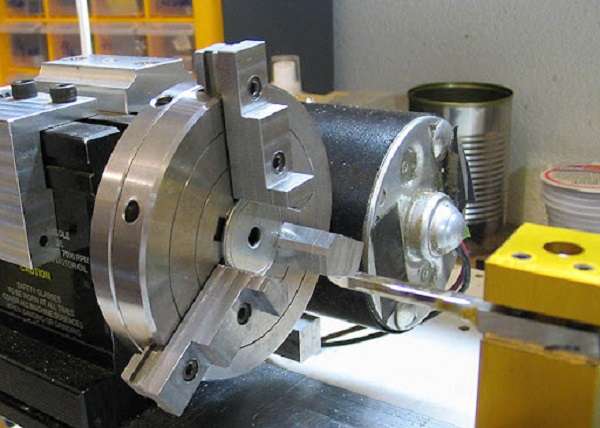

In machining, a jaw chuck with 3 jaws is a typical tool for holding work, especially on CNC machines and lathes. It is set to hold and turn around or hexagonal workpieces significantly and highly accurately.

The chuck has 3 jaws that move synchronously, and this centers the workpiece. This makes it very effective in repetitive jobs that do not need much time to set up and are accurately aligned.

What does a 3-jaw chuck stand for?

The expression 3-jaw chuck denotes a self-centering chuck, having three jaws (which swing synchronously) to firmly grip a workpiece.

It is developed so that it grabs symmetrical pieces, e.g., round rods or hexagonal bars, and thus it is best suited to fast and high-precision machining.

Applications of a 3-jaw chuck include:

- Turning operations: Cylindrical stock held between cylindrical collets on a lathe to shape, thin down, or profile.

- Facing and drilling :They are involved in offering rigidity when machining flat surfaces or the formation of center holes in workpieces.

- Boring:It makes drilling new holes and expanding on the old holes easy.

- CNC machining: In mass production, to is used in programmable machines that maintain consistent clamping.

- General metalworking and fabrication: Applicable across any job using a round or symmetrical feature, which is common in the automobile, aerospace, and machine shop industries.

Owing to the easy accessibility of use and the rapid speed of clamping, the 3-jaw chuck is a favorite among machinists who seek to combine the pace, precision, and comfort in their day-to-day routine.

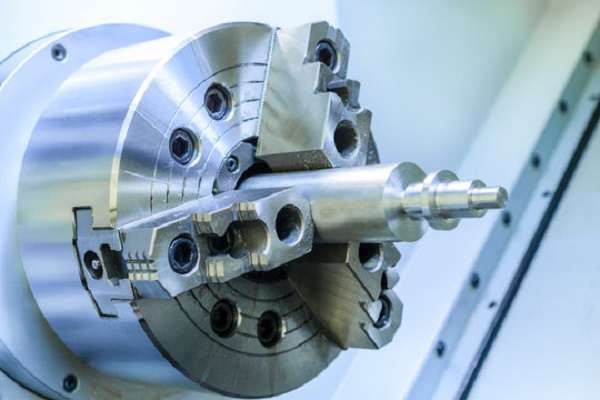

3. What is a 4-Jaw Chuck?

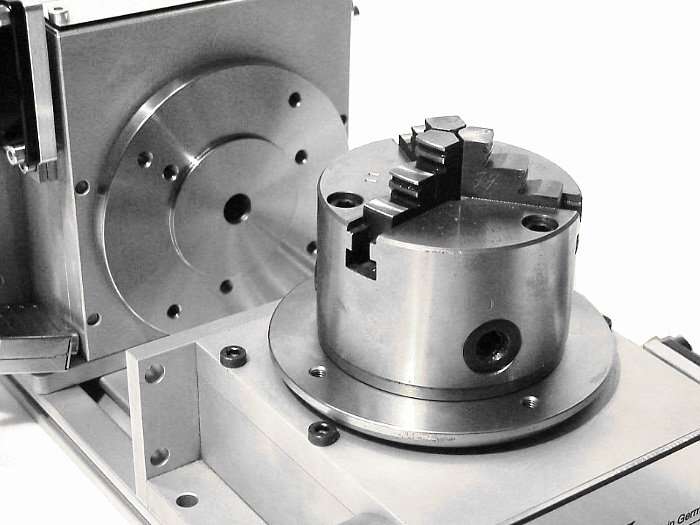

A 4-jaw chuck is one types of chuck used in lathes; it consists of four independent, manually movable jaws that can all be rotated apart from one another.

It is especially valuable in clamping irregular, square-shaped, rectangular, or non-cyclical workpieces that cannot be automatically centered.

It can also perform more advanced machining work due to its ability to clamp workpieces off center, e.g., to turn a non-centric shape, or to cut other complex shapes.

The 4 jaw chuck advantages is flexible and its positioning precision is high; this makes it ideal in complex machining undertakings where precision and ideal positioning, as well as custom clamping, are necessary.

Define 4-Jaw Chuck

The metalworking and precision machining sectors make extensive use of four jaw chuck,which are manual, non-self-centering chucks.

It provides greater flexibility for clamping different shapes because each jaw is independent, and this allows fine adjustments to provide centering with high-eye accuracy.

What Does 4-Jaw Chuck Mean?

The term 4-jaw chuck refers to the chucking device that operates utilizing four jaws that can be separately adjusted to hold onto a piece of work.

It is handy, especially in materials that are asymmetrical or irregular, and it gives greater control as well as balanced clamping force application.

4. 4-Jaw Chuck Application

In contrast to 3-jaw chucks, which can only have their jaws changed together, 4-jaw chucks are completely autonomous and feature jaws that may be separately positioned.

This aspect renders it very suitable in non-symmetric components, square and rectangular material, as well as those requiring careful centering.

What is a 4-jaw chuck application?

The application of the 4-jaw chuck can be described as one that requires the application of a 4-jaw independent chuck in lathe jobs requiring custom positioning, accurate alignment, and a tight grip.

The jaws are adjustable individually, and therefore, the chuck can clamp a broad range of shapes that an ordinary self-centering chuck would not have the capacity to do.

And this entails square bars, irregular castings, centering of turning, and fragile spares that need special jaw settings in order to prevent distortion.

Common applications of a 4-jaw chuck include:

- Turning square or rectangular workpieces:A good place where non-cylindrical objects could be kept.

- Eccentric turning or Off-center work:Allows specifically non-aligned fits to perform specialized machining processes.

- Precision centering tasks:Handy in case of precision in position when working with high tolerance.

- Machining irregular or rough-cast parts:Particularly useful for special work or repair work.

- Clamping delicate or thin materials:Either jaw can be placed to exert equal pressure and cause the least injury.

The 4-jaw chuck is a common, easy-to-go-to solution in industries where machinists require maximum control over the clamping and positioning, including the aerospace, tool making, custom fabrication, and restoration businesses.

The lathe may be ten times more accurate as well as versatile with a 3-jaw chuck, but the installation time is shorter.

5. How to Choose Between a 3 Jaw Chuck and 4 Jaw Chuck for Your Application?

Think about the machining task, the workpiece's shape, and the level of precision required when deciding between a 3-jaw vs 4-jaw chuck.

Every chuck possesses its advantages and disadvantages, and the most suitable one to use should be determined by your needs, i.e., whether you need to quickly center them or perform flexible and ultra-precise clamping of an irregular shape. So what is the difference between three jaw chuck and four jaw chuck?

Choose a 3-jaw chuck if:

- You are using hexagonal or round workpieces.

- You should have faster installation and automatic centering.

- You work on a line machine at high speed and repetition.

- The task can be performed with low accuracy.

- You are looking forward to a more convenient, time-saving tool for symmetrical parts.

Choose a 4-jaw chuck if:

- You require the machining of square, rectangular, or irregular-shaped workpieces.

- You need a sophisticated accuracy centering on special jobs or custom work.

- The work implies eccentric or offset turning.

- You desire additional flexibility and control of clamping.

- You are engaged in customized fabricating, fixing, or prototyping.

Comparison of the difference between three jaw chuck and four jaw chuck

- Independent Jaws vs. Self-Centering: A 3-jaw chuck automatically centers round workpieces, but a 4-jaw chuck gives the ability to move the jaws independently, giving improved precision and flexibility when dealing with more complicated shapes.

- Speed vs Precision:The 3-jaw setup is quicker, whereas the 4-jaw is more versatile and precise.

- Shape Compatibility:The 3-jaw chuck is favored where a symmetrical piece is to be worked on, but the 4-jaw chuck can work with more shapes.

In summary, when your application requires speed and ease of operation using standard shapes, a 3-jaw chuck is an ideal choice.

A 4-jaw chuck is a more suitable alternative, however, when you need more accuracy and the ability to operate with irregular shapes. So what is the difference between three jaw chuck and four jaw chuck? I think you have found the answer.

Conclusion

So, what is the difference between three jaw chuck and four jaw chuck?

To choose the appropriate chuck, you should base it on your workpiece shape, the accuracy required for your workpiece, as well as the type of machining activity.

A 3-jaw chuck is self-centering, conducive, and good to use in fastening round or hex-shaped parts, hence applicable to general purposes in machining. Nevertheless, it is not very flexible and has middling-level accuracy.

On the contrary, the 4-jaw chuck permits freedom of movement of jaws, which facilitates precise positioning and makes it capable of holding irregular or non-cylindrical workpieces.

It is faster to load and use, and more accurate, but it will take more time to set up and requires more skill. The two are differentiated by the issue of what matters to you, namely, whether you prioritize speed or accuracy.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024