Stainless Steel Sheet Sizes Chart: A Designer’s & Engineer’s Handbook

Introduction

Discover the comprehensive Stainless Steel Sheet Sizes Chart, featuring standard thicknesses, dimensions, and gauges. An ideal sheet over whom builds, fabricators, and DIYers requires proper sizing details.

1. What is the stainless-steel sheet size chart?

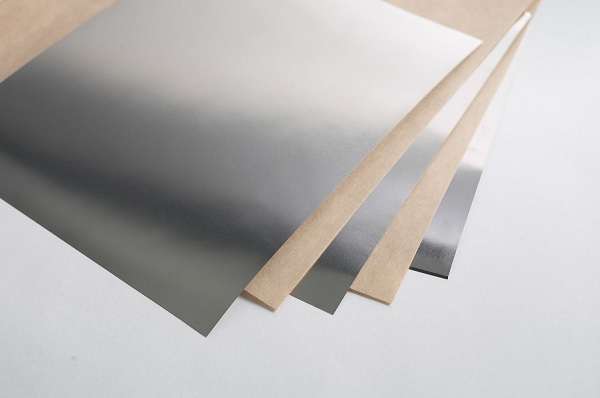

The stainless-steel sheet size chart is a valuable reference tool that provides detailed information on the standard sizes of stainless-steel sheets used in various applications, including construction, manufacturing, and fabrication.

The stainless-steel sheet size includes vital measurements such as thickness, width, length, and gauge, allowing users to easily identify the appropriate stainless steel sheet size for their specific needs.

Available in both imperial and metric units, it also features a precise stainless-steel sheet size chart in mm, making it suitable for international use.

The stainless-steel sheet dimensions chart ensures accurate planning and material selection, helping to reduce waste, improve efficiency, and ensure compatibility with project requirements.

Whether you're a professional or a DIY enthusiast, this chart is essential for achieving precise and reliable results.

| Gauge | US Standard for steel sheet in inches(mm) |

Steel inch (mm) |

Galvanised stoel inch (mm) |

Stainless steel inch (mm) |

Aluminium inch(mm) |

| 3 | 0.2500(6.35) | 0.2391(6.07) | - | - | - |

| 4 | 0.2344(5.95) | 0.2242(5.69) | - | - | - |

| 5 | 0.2188(5.56) | 0.2092(5.31) | - | - | - |

| 6 | 0.2031(5.16) | 0.1943(4.94) | - | - | 0.162(4.1) |

| 7 | 0.1875(4.76) | 0.1793(4.55) | - | 0.1875(4.76) | 0.1443(3.67) |

| 8 | 0.1719(4,37) | 0.1644(4.18) | 0.1681(4.27) | 0.1719(4.37) | 0.1285(3.26 |

| 9 | 0.1563(3.97) | 0.1495(3.80) | 0.1532(3.89) | 0.1563(3.97) | 0.1144(2.91) |

| 10 | 0.1406(3.57) | 0.1345(3.42) | 0.1382(3.51) | 0.1406(3.57) | 0.1019(2.59) |

| 11 | 0.1250(3.18) | 0.1196(3.04) | 0.1233(3.13) | 0.1250(3.18) | 0.0907(2.30) |

| 12 | 0.1094(2.78) | 0.1046(2.66) | 0.1084(2.75) | 0.1094(2.78) | 0.0808(2.05) |

| 13 | 0.0938(2.38) | 0.0897(2.28) | 0.0934(2.37) | 0.094(2.4) | 0.072(1.8) |

| 14 | 0.0781(1.98) | 0.0747(190) | 0.0785(1.99) | 0.0781(1.98) | 0.0641(1.63) |

| 15 | 0.0703(1.79) | 0.0673(1.71) | 0.0710(1.80) | 0.07(1.8) | 0.057(1.4) |

| 16 | 0.0625(1.59) | 0.0598(1.52) | 0.0635(1.61) | 0.0625(1.59) | 0.0508(1.29) |

| 17 | 0.0563(1.43) | 0.0538(1.37) | 0.0575(1.46) | 0.056(1.4) | 0.045(L.1) |

| 18 | 0.0500(1.27) | 0.0478(1.21) | 0.0516(1.31 | 0.0500(1.27) | 0.0403(102) |

| 19 | 0.0438(1.11) | 0.0418(106) | 0.0456(1.16) | 0.044(1.1) | 0.036(0.91) |

| 20 | 0.0375(0.95) | 0.0359(0.91) | 0.0396(1.01) | 0.0375(0.95) | 0.0320(0.81) |

| 21 | 0.0344(0.87) | 0.0329(0.84) | 0.0366(0.93) | 0.034(0.86) | 0.028(0.71) |

| 22 | 0.0313(0.80) | 0.0299(0.76) | 0.0336(0.85) | 0.031(0.79) | 0.025(0.64) |

| 23 | 0.0281(0.71) | 0.0269(0.68) | 0.0306(0.78) | 0.028(0.71) | 0.023(0.58) |

| 24 | 0.0250(0.64) | 0.0239(0.61) | 0.0276(0.70) | 0.025(0.64) | 0.02(0.51) |

| 25 | 0.0219(0.56) | 0.0209(0.53) | 0.0247(0.63) | 0.022(0.56) | 0.018(0.46) |

| 26 | 0.0188(0.48) | 0.0179(0.45) | 0.0217(0.55) | 0.019(0.48) | 0.017(0.43) |

2. What materials are used for stainless-steel sheets?

Stainless steel sheets are manufactured through the use of metals and alloying materials that provide their strength, resistance to corrosion, as well as durability. The following are the major materials used:

· Iron (Fe)

Stainless steel has iron, which forms the base metal. It gives strength and is the backbone of the alloy.

· Chromium (Cr)

The most important component that makes steel acquire the stainless aspect is chromium. Steel is resistant to rust and corrosion because of the protective layer of chromium, which forms a tiny amount of oxide on the surface and is at least 10.5% pure.

· Nickel (Ni)

Nickel improves the material's hardness, formability, and resistance to corrosion. Grade 304 and grade 316 austenitic stainless steel, among others, require their utilization.

· Molybdenum (Mo)

Molybdenum increases pitting and crevice resistance. It is widely applied to marine-grade stainless steels, e.g., type 316.

· Carbon (C)

Carbon renders the metal hard and strong. It is, however, typically maintained at low levels in stainless steels to ensure weldability and corrosion resistance.

· Manganese (Mn)

Manganese also contributes towards increasing strength and hot-working, and in particular grades of stainless steel, may even partially replace nickel.

· Silicon (Si)

The addition of silicon provides oxidation resistance and contributes to strength at high temperatures.

A combination of the materials in varying ratios is used depending on the grade of stainless steel, each of which finds areas of application in various environments, construction, the food processing industry, marine, and so on.

3. What is the application of the stainless-steel sheet?

Stainless steel sheets are recognized as a strong material with high resistance to corrosion, hygienic, and aesthetically appealing, which is why they are a desired material in many industries. The key applications are provided below:

· Architecture and Construction

The use of stainless-steel sheets in modern buildings is extensive in such elements as facades, roofing, wall cladding, doors of lifts, and handrails.

They have high resistance to weather and corrosion to deliver long-term service inside and outside. Architectural designs are also complemented by the aesthetic value of brushed or smooth refining.

· Food and Kitchen Processing

Stainless steel sheets are also critical in the food industry because of their non-porous, hygienic, and easy-to-clean surface.

They are applied in kitchen countertop surfaces, sinks, splash backs, food handling and preparation tables, and commercial cookware. They react neither with food nor with cleaning chemicals, and thus, they are best suited to carry out food safety issues.

· Automotive and transportation

Stainless steel finds widespread application in the automobile sector, where it is used for trailers, gasoline tanks, exhaust systems, and car trim.

They are lightweight and corrosion-resistant, which adds to performance and long durability. The stainless steel in railways and aerospace is used in panels, compartments, and protective barriers.

· Medical and Pharmaceutical Applications

Surgery tools, hospital furniture, laboratory tables, and sterilization areas are all best suited to stainless steel sheets since the disinfectants will not corrode them, and you will only need to sterilize them, making them easily sterilized and biocompatible.

· Chemical and Marine Industry

Such special grades are the 316 stainless steel, special grades that have been applied in chemical plants, storage tanks, marine vessels, docks, and hardware due to their superiority in resisting the chlorides, acids, and saltwater corrosion.

· Interior Design and Furniture

Stainless steel is also used in modern interiors where it is preferred for decoration panels, furniture, light, and kitchen appliances, giving modern interiors a touch of fashion and a long-lasting impact inside the house and on the business.

The stainless-steel sheets are versatile and competent, and therefore, are a must in all industries that require durability, hygiene, and a corrosion-free product.

4. How to choose the right stainless-steel sheet?

Choosing the appropriate stainless-steel sheet is essential in maintaining durability, functionality, and cost effectiveness in your project. Whether you're working in construction, manufacturing, or interior design, the following factors will help guide your choice:

· Understand Your Application

Start by stating a proper aim of the sheet. Does it support the structure, does it have decorative finishing, and are these hygienic or corrosive conditions? Depending on the intended use, the grade, thickness, and finish required shall be determined.

· Choose the Right Grade

Stainless steel is available in several grades, with each having distinctive properties:

- 304 Stainless Steel:Multipurpose and non-corrosive, suited to kitchen, food, and general applications.

- 316 Stainless Steel:Has another compound of molybdenum so that it can resist corrosion better; ideal in marine projects, chemical applications, or open environments.

- 430 Stainless Steel:A cheaper option that is magnetic and can be used decoratively or indoors, where there is also a low risk of corrosion.

· Determine the Required Thickness

Thickness influences strength, weight, and flexibility:

- Thin sheets (0.5-2mm): Most suitable for light-duty, flexible, or decorative uses.

- Thicker sheeting (3 mm+) :Suitable for structural work, weight-bearing sections, or areas that run the risk of impact.

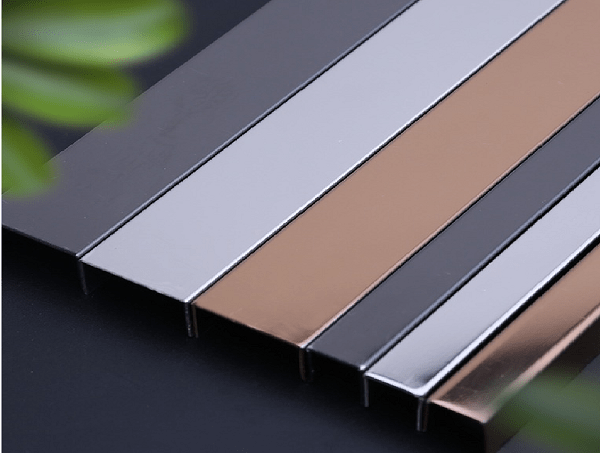

· Select the appropriate Surface Finish

The finish of the surface influences structure and aesthetics:

- 2B Finish: smooth, flat matte, general purpose.

- 4 finish: brushed and is mostly found in kitchen appliances.

- BA (Bright Annealed): It is shiny, reflective, and is best suited for decoration.

- Mirror Finish: Very smooth and suitable for use in architectural and design projects.

· Consider the Environment

Compare the grade with environmental conditions:

- 316:Salty, chemical, or humid environments.

- 304 or 430:Indoors, dry, or less stringent requirements.

· Trade-off Cost and Performance

Sheets with a higher grade are more expensive, yet they work better and last longer. Decide on long-term value, not up-front cost.

With the help of an assessment of your application, environment, and budget, it is possible to pick the proper stainless-steel sheet according to your requirements and guarantee the quality performance.

Conclusion

To pick the correct stainless-steel sheet, it is important to understand the stainless-steel sheet sizes chart. Whether you're working in construction, manufacturing, or design, knowing the available dimensions, thicknesses, and standard formats helps ensure efficiency, proper fit, and cost control.

The chart is also a time-saving source of information, enabling users to match sheet sizes to application requirements, thereby saving materials and fabrication time.

Choosing the proper sheet size will affect its durability and performance in both small-scale DIY and large industry-level applications. Making an informed decision that meets the industry standards is made possible by referring to an industry-reliable chart of stainless-steel sheet sizes in mm or inches.

You should always take into consideration the grade as well as the dimensions to suit your project's structural and aesthetic needs.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024