Aluminum Sheet Sizes Chart: Standard Dimensions & Gauges

Introduction

Find out the common sizes of aluminum sheets using this readable chart. Explore dimensions, thicknesses, and general purposes of aluminum sheet to select the best project.

1. What is the aluminum sheet size chart?

The chart of aluminum sheet size is a descriptive master list that illustrates the general dimensions of an aluminum sheet by its length, width, and thickness.

It makes it easy for users to identify and compare different aluminum sheet sizes charts that can be used in several different projects, like construction projects, fabrication, car-related work, and DIY projects.

These charts are normal to be in both inches and millimeters (mm), considering their compatibility worldwide and allowing easy choice.

The aluminum sheet size chart in mm will give you accurate measurements as to which size to use, whether you are working with thin-gauge sheets that would make up lightweight structures or thick sheets that would be heavy-duty.

Also, an aluminum sheet dimensions chart enhances efficient performance because individuals, as well as hobbyists, can plan precisely, cut less waste, and fit correctly. The employment of this chart will save the proper balance of power, suppleness, and size, concerning each project's needs.

| TICKNESSES | SIZES | |||

| 1000x 2000 | 1250x 2500 | 1500x 3000 | 2000x 4000 | |

| 0.40 | 6.40 | 10 | X | X |

| 0.50 | 8 | 12.5 | X | X |

| 0.60 | 9.60 | 15 | 21.6 | X |

| 0.70 | 11.2 | 17.5 | 25.2 | × |

| 0.80 | 12.8 | 20 | 28.8 | X |

| 1.00 | 16 | 25 | 36 | X |

| 1.25 | 20 | 31.25 | 45 | X |

| 1.50 | 24 | 37.5 | 54 | 96 |

| 2.00 | 32 | 50 | 72 | 128 |

| 2.50 | 40 | 62.5 | 90 | 160 |

| 3.00 | 48 | 75 | 108 | 192 |

| 4.00 | 64 | 100 | 144 | 256 |

| 5.00 | 80 | 125 | 180 | 320 |

| 6.00 | 96 | 150 | 216 | X |

| 8.00 | 128 | 200 | 288 | X |

| 10.00 | 160 | 250 | 360 | X |

| 12.00 | 192 | 300 | 432 | X |

2. What materials are used for aluminum sheet?

Sheets of aluminum are made from a variety of alloys, which include not just aluminum but also calcium, manganese, silicon, copper, and silver.

These alloys strengthen and improve the other properties, including corrosion resistance, weldability, and formability, so that the aluminum sheets find vast use in industrial and commercial applications.

· Pure Aluminum (1xxx Series)

The series includes 99 percent or more of aluminum. It has very good resistance to corrosion, high temperature, and electrical conductivity, and is easily formed.

It is, however, relatively weak, thus suitable for applications in electrical, chemical, and food processing industries.

· Aluminum-Manganese Alloys (3xxx Series)

Moderate strength and very good corrosion resistance are provided by these sheets. They find popular usage in roofing, siding, cookware, and storage tanks because they are easily shaped and are resistant to atmospheric corrosion.

· Aluminum-Magnesium Alloys (5xxx Series)

The type is strong and has had great corrosion resistance, particularly in seawater. Such sheets can be deployed for boat building, servicing operations, and construction purposes.

· Heat-Treatable Alloys (2xxx, 6xxx, 7xxx Series)

- 2xxx (Aluminum-Copper): Extra-light, strong, and applied in the field of aerospace.

- 6xxx (Aluminum-Magnesium-Silicon): All-purpose and weldable, which is suitable for construction and transport.

- 7xxx (Aluminum-Zinc): powerful, applied on aircraft and sports equipment.

Different types of alloys come with their advantages; thus, aluminum sheets can be used in various projects and industries.

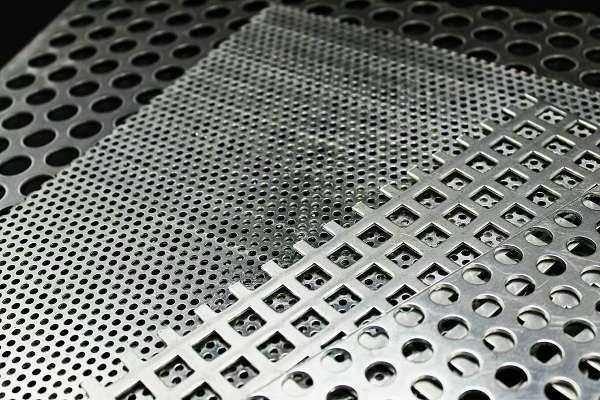

3. What is the application of the aluminum sheet?

Aluminum sheets have become very common in many industries due to their lightweight, durability, resistance to rust, and cost.

They are essential in many different businesses and even in our everyday lives due to their versatility. Here are a few examples of where aluminum sheet is commonly used:

· Construction and Architecture

Aluminum sheets find application in the construction of structures in the use of roof, wall cladding, facades, ceilings, gutters, and window frames.

These have high resistance to weathering, corrosiveness, and UV sunlight rays; they can be used both internally and externally, and they also have a sleek, modern style.

· Automotive and Transportation

The use of aluminum sheets is widespread in the manufacture of cars, trucks, trailers, trains, and buses.

They can be used on body panels, hoods, doors, and even structural reinforcements as they are lightweight and contribute toward better fuel economy and lower car weights.

· Aerospace Industry

The aerospace industry massively uses aluminum sheets of high strength in manufacturing its parts, typified by the airplane bodies, wings, fuselage, airframes, and fuselage sections.

A flight's performance and use of fuel are greatly affected by aluminum's exceptional strength-to-weight ratio.

· Marine Applications

The boat hulls, decks, as well as offshore structures are made of aluminum sheets, mainly of the 5xxx series, which has a high resistance to corrosion in saltwater.

· Packaging Industry

Such foils and sheets of aluminum are used in the form of packaging of food, beverages, and even medicines. They have good barrier characteristics in ensuring that contents remain fresh.

· Consumer Products

Aluminum sheets can be found in appliances, cookware, signage, electronics, and furniture, and they are good-looking and work well.

Aluminum sheets are critical in applications where there is a necessity to maintain the balance of strength, lightness, and durability.

4. How to choose the right aluminum sheet?

The selection of appropriate aluminum sheet entails assessment of your technical requirements, physical environment, and budget. Aluminum sheets are available in alloys, in various thicknesses and finishes that are always used differently.

Here is everything you need to know to make a correct choice:

· Identify the Application

First of all, outline the use and positioning of the aluminum sheet. Each application (construction, transportation, marine, aerospace, or decorative work) requires certain properties of minutiae.

An example is the need for high corrosion resistance in marine use, and a high strength-to-weight ratio in aerospace.

· Select the Appropriate Alloy Series

Aluminum sheets come in series, with each having various characteristics:

- 1xxx (Pure Aluminum): Good corrosion and workability properties, which make it viable in the chemical and food Industries.

- 3xxx Series (Aluminum-Manganese): Easy bending, decent strength, used as cooking ware and roofing.

- 5xxx Series (Aluminum-Magnesium):Its exceptional corrosion resistance and high strength make it an excellent choice for structural and marine uses.

- 6xxx Series (Aluminum-Magnesium-Silicon): High strength with good weldability, which is predominantly applied in construction and transportation.

- 7xxx Series (Aluminum-Zinc): Extremely strong, generally applied in space applications, and heavy-duty.

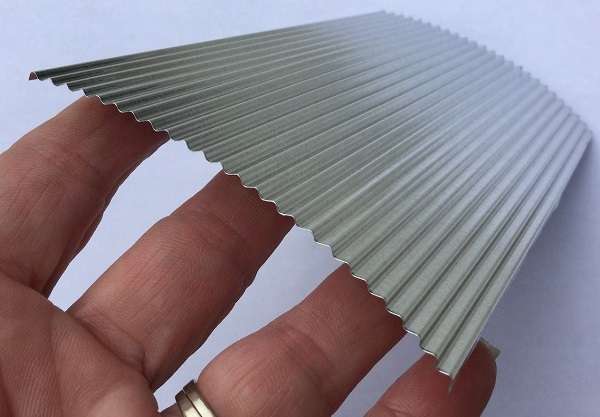

· Choose the Right Thickness and Size

Strength, weight, and flex are influenced by thickness. The lightweight projects or cladding are better accommodated by thinner types of sheets (0.5mm to 2mm), whereas heavier structural and industrial uses are suited to the thicker sheets (3mm and up).

· Consider Surface Finish

In cases involving aesthetics, as an application, select either brush finishes, anodized, or polished. Treatment of the surface not only enhances the look, but it also provides additional protection against corrosion.

· Evaluate Corrosion Resistance

To use outdoor or marine conditions, give preference to the alloys resistant to corrosion, such as the 5xxx or 6xxx series. They work out in moisture, salt water, and in industrial conditions.

· Factor in Workability and Cost

Select high-form alloys in those projects that require bending or shaping. In addition, balance your budget and performance, remembering that in cases where strength is not vital, you can opt to use cost-effective options.

Through these considerations, you are assured of making the right choice in choosing the right aluminum sheet that can satisfy your functional, as well as economic, requirements.

Conclusion

Knowing which aluminum sheet size chart to use is critical in selecting materials for various sectors of the construction, automotive, marine, and packaging industries.

This chart lists standard sizes of aluminum sheets, including length, width, and thickness, to help you determine the best fit, functionality, and compatibility for your specific project requirements.

It comes as an inch (in) and as a millimeter (mm), and it can easily be compared and selected as needed. Besides the size, the suitability of the aluminum alloy, surface treatment, and thickness can be chosen; this will improve the durability, corrosion resistance, and cost.

As a professional or a DIY enthusiast, a more comprehensively compiled chart of aluminum sheet dimensions makes material selection easier and helps improve planning, fabrication, and installation to achieve successful project delivery.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024