Boost Your Production Quality: Why Invest in a Gear Chamfering Machine?

Introduction

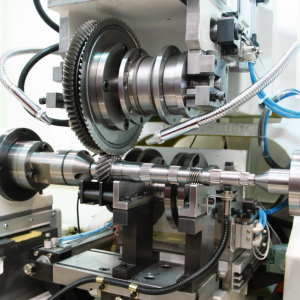

Gears that are not smoothed properly can break other parts. A special machine called a gear chamfering machine can fix this issue. The machine helps make gears very smooth. This article explains why using one of these machines makes your gear factory work much better.

Key Takeaways:

- Gear chamferingis essential for optimal gear performance and longevity.

- Gear chamfering machinesenhance precision, boost gear manufacturing efficiency, and reduce costs.

- Choosing the right machine involves considering precision, durability, and user interface.

- Advancements in CNC technologyare transforming gear chamfering, driving production optimization and sustainability.

In this article, we will look at what is chamfering,and the importance of gear chamfering, the key benefits provided by specialized chamfering machines, what features to look for when selecting this equipment, and future innovations that promise to make the process even more streamlined. Read on to learn why transitioning from manual to automated chamfering can give gear manufacturers a real competitive edge.

1.what is chamfering

So,what is chamfering?

Chamfering means using a machine to smooth the sharp edges of gear teeth. Gears need their teeth edges chamfered so they do not ruin other parts that touch the gears. Chamfering makes the gears work right and not hurt other parts. Doing it by hand takes very long and is not as good. Using a special chamfering machine is faster and smoother.

Proper chamfering of the gear teeth makes the gears run quiet and not get stuck. It makes your factory have less broken gears to throw away. In big planes or rockets, bad gears can even make very bad accidents happen. So those factories need their gear chamfering to be flawless, which means perfectly smooth. The best chamfering machines help make flawless gears.

2.Benefits of Gear Chamfering Machines

Chamfering machines are much better than trying to smooth gears by hand filing. Here is how they help:

Improved Production Quality

The programmed machines chamfer with complete precision, meaning extremely accurately. They make all the gears have the exact right amount of smoothness. This prevents bad chamfers that leave sharp bits or over-grind too much off. The precision also means you have to throw away fewer broken gears. For example, one airplane part factory went from 11% broken parts down to only 0.05% thanks to a chamfering machine. This kind of quality improvement saves lots of money and time.

Increased Efficiency

A chamfering machine takes minutes to chamfer gears smoothly instead of having workers use hand files for hours. The machines are fast because they load and unload the gears on their own. Their controls are also easy to program. All this together means you can make more gears per day without hiring more people. If you have a factory running night and day, the efficiency gains are even bigger, saving you even more on workers.

Cost Savings

Buying a chamfering machine quickly pays for itself from all the money it saves:

- Less workers to pay

- Fewer broken gears wasted

- The special ceramic cutters last longer than regular tools

- Smooth gears do not wear out as fast, so you do not have to replace them

You also can take on more business since your factory makes gears faster. All these savings mean the machines give you high return on investment.

3.Key Features to Look for in a Gear Chamfering Machine

To get those benefits, you need the right chamfering machine. Here are key features to check:

Precision and Accuracy

Good precision is vital so the gears work correctly. Seek machines that can smoothly chamfer within 0.02mm accuracy. Details like ball screws, strong frames, and the best cutting tools give precision. CNC computers also repeat cuts perfectly every time. These qualities let the machines meet very strict requirements.

Durability and Maintenance

Since the machines run 24/7, they must be very sturdy and stable. Important parts like spindles should resist vibration. Ball bearings avoid loose play. And it helps if machines handle heat changes well so the accuracy does not suffer. You should also be able to easily service the machines as needed to keep them in tip-top shape.

User-Friendly Interface

The machine controls must be easy for operators to understand quickly to avoid errors. Conversational programming walks new staff through. But experienced users still can tweak settings. Touchscreens make navigation intuitive. Smart data collection can even improve production. If the interface works with the operator nicely, your chamfering gets done faster and without issues.

4.Future Trends in Gear Chamfering Technology

While today's CNC chamfering machines are great, new innovations will make them even better:

Advancements in CNC Technology

Future CNC computers will use artificial intelligence to keep improving production. As they gather data, the machines self-optimize to prevent almost all defects. IoT networking also lets managers monitor and instantly adjust chamfering from anywhere. And automatic inspection catches the very rare quality problems before anything ships out. Intelligent CNC promises to take automated gear chamfering to the next level.

Sustainability and Eco-Friendly Practices

Along with getting smarter, the newest chamfering machines are becoming greener. Energy efficient parts reduce power needs while staying ultra-precise. Instead of dangerous materials, recycled and renewable ones build the machines now. Efficient designs also cut waste. And solar power can run some units completely emission-free. At all steps, sustainability guides decisions to make automated chamfering an eco-friendly choice over the old hand filing method.

Conclusion

Switching from hand filing to automated CNC chamfering makes major boosts in quality, speed, and reliability that help manufacturers compete strongly.

The machines do the hard work precisely and fast while lasting for years and costing less overall. Looking ahead, smart green technology will improve them even more. Any factory that must produce perfect gears should think about adding chamfering machines for best production and profits in the future.

Checking your current gear process manufacturing and upgrading old machines ought to be a top goal if you want to stay in business as things change.

Consider evaluating your gear manufacturing process and explore the benefits of incorporating a gear chamfering machine for improved chamfering efficiency and optimized industrial machinery performance.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024