Sheet Metal Gauge Chart

Introduction

With sheet metal, it is of paramount importance to know about the sheet metal gauge chart. This table describes the standard thicknesses of the metals, which makes it easier to choose the best material to use for a certain project. However, no matter whether you are working with a "copper gauge chart”, “aluminium gauge chart”, “stainless steel gauge chart”, or “galvanised steel gauge chart”, the gauge thickness information is crucial for increasing effectiveness.

In this article, let me explain to you how the sheet metal gauge chart helps, some of the key uses for the chart, and how you can get the most out of the chart for your job. Looking at this chart it is not merely about counting but more about creating better quality and more durable work.

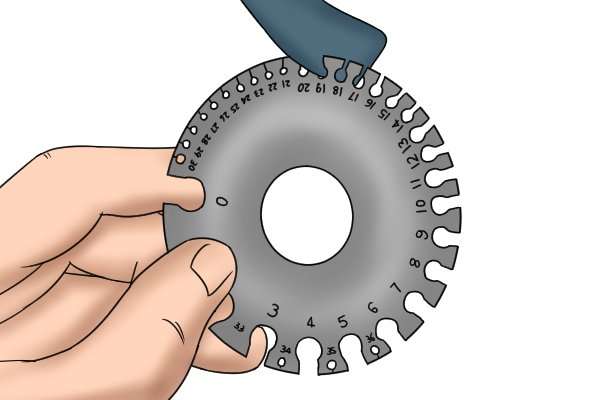

1.What is Sheet Metal Gauges Used For?

A tool known as a “sheet metal gauge chart” is commonly used across various fields to establish the thickness of the sheet metal. In construction, automotive, and manufacturing industries, metal thickness is of critical importance in providing the quality of the material needed to be used. For this reason, by using the “sheet metal gauge chart”, professionals are capable of choosing the thin-base metal thickness they need.

*For instance, the ‘copper gauge chart’ is one of the most relevant tools that should be used while performing tasks in electrical wiring and plumbing works. Copper is mostly famed for its conductivity characteristic, and consequently, the thickness has to be as close to ideal as possible. Likewise, the aluminium gauge chart is common in aviation and auto industries, where costs may require part formations that are thin yet strong plus sturdy. This way, the correct thickness of the aluminium is known, and this assists in ensuring the appropriate structure of cars and planes.

Another important tool is the “stainless steel gauge chart,” especially when used in industries that need to deal with corrosion problems. Stainless steel is used in numerous applications, starting from kitchen utensils and ending with devices for various medical purposes; the required thickness is important for both the reliability and productivity of the material. Last but not least is the ‘galvanised steel gauge chart’, which is especially characteristic for construction projects due to the high resistance of such metal to rusting and great durability. This material is used for roofing, fences, and other outdoor structures where corrosion resistance is important, and the gauges of this material determine how well it will perform under these conditions.

So, the ‘sheet metal gauge chart’ is a tool that guides professionals in choice of material. This way, the chosen material will be delivered as required in certain circumstances and output, thus ensuring the durability of the end products.

2.Compare the Steel Gauge vs Thickness

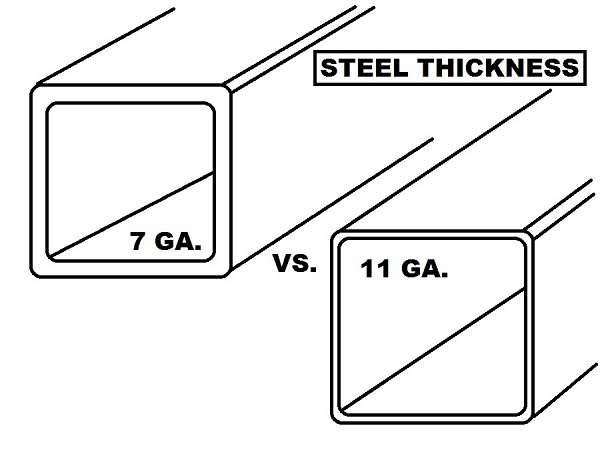

Probably one of the most important considerations when using a “sheet metal gauge chart” is the correlation between gauge and thickness. The term “gauge” might seem straightforward, but its relationship with thickness is inverse. Here, it is also seen that as the gauge number increases, the thickness of the material decreases. This relationship can sometimes be confusing, especially when determining some differences between the “steel gauge vs thickness” for the various materials.

For instance, the phrase “stainless steel gauge chart”, the lower gauge number like 12, is representative of the thicker sheet of the material as compared to a higher gauge number like 22. These two figures demonstrate an inverse trend in their respective charts, such as the galvanised steel gauge chart and the aluminium gauge chart. Knowledge of this concept is useful when trying to choose between the “steel gauge vs thickness” to obtain the required material.

It also uses the “sheet metal gauge chart” that gives out standard measurements, hence the comparisons. For instance, whenever one is using the “copper gauge chart,” one has to note that a copper sheet at 14 gauge will be thicker and heavier than copper at 20 gauge. This is particularly relevant in projects such as roofing or plumbing since weight acts as an important factor.

One of the considerations to make when comparing the two, steel gauge vs thickness, is the kind of steel being used. Different materials are composed of different densities and characteristics; thus, thickness varies w.r.t strength and life. A small thickness, such as a 16-gauge stainless steel sheet, might be different in terms of strength from a 16-gauge aluminium sheet. Variability of the thickness of these materials increases the need to consider the particular characteristics of every material while reflecting on the “sheet metal gauge chart”.

Consequently, steel gauge versus thickness comparison is one of the critical elements that can help choose the most appropriate material for project implementation. Therefore, with the help of the “sheet metal gauge chart”, a professional will be able to select the right thickness, strength, and multiple other attributes to meet the needs of the applied task.

| GAUGE | ALUMINUM BRASS |

COLD HOT ROLLED |

TUBES COPPER |

STAINLESS | GALVANIZED | GAUGE | ||||

| NUMBER | SHEET INCH |

MM | SHEET INCH |

SHEET INCH |

MM | SHEET INCH |

SHEET INCH MM |

NUMBER | ||

| 3 4 5 |

0.229 0.204 0.182 |

5.827 5.189 4.620 |

0.239 0.224 0.209 |

6.073 5.695 5.314 |

0.259 0.238 0.220 |

6.579 6.045 5.588 |

3 4 5 |

|||

| 6 | 0.162 | 4.115 | 0.194 | 4.935 | 0.203 | 5.156 | ||||

| 7 | 0.144 | 3.665 | 0.179 | 4.554 | 0.180 | 4.572 | ||||

| 8 | 0.129 | 3.264 | 0.164 | 4.176 | 0.165 | 4.191 | 0.172 | 4.365 | 0.168 4.270 | 8 |

| 9 | 0.114 | 2.906 | 0.150 | 3.797 | 0.148 | 3.759 | 0.156 | 3.969 | 0.153 3.891 | 9 |

| 10 | 0.102 | 2.588 | 0.135 | 3.416 | 0.134 | 3.404 | 0.141 | 3.572 | 0.138 3.510 | 10 |

| 11 | 0.091 | 2.304 | 0.120 | 3.038 | 0.120 | 3.048 | 0.125 | 3.175 | 0.123 3.132 | 11 |

| 12 | 0.081 | 2.053 | 0.105 | 2.657 | 0.109 | 2.769 | 0.109 | 2.778 | 0.108 2.753 | 12 |

| 13 | 0.072 | 1.828 | 0.090 | 2.278 | 0.095 | 2.413 | 0.094 | 2.381 | 0.093 2.372 | 13 |

| 14 | 0.064 | 1.628 | 0.075 | 1.897 | 0.083 | 2.108 | 0.078 | 1.984 | 0.079 1.994 | 14 |

| 16 | 0.051 | 1.291 | 0.060 | 1.519 | 0.065 | 1.651 | 0.063 | 1.588 | 0.064 1.613 | 16 |

| 18 | 0.040 | 1.024 | 0.048 | 1.214 | 0.049 | 1.245 | 0.050 | 1.270 | 0.052 1.311 | 18 |

| 20 | 0.032 | 0.812 | 0.036 | 0.912 | 0.035 | 0.889 | 0.038 | 0.953 | 0.040 1.006 | 20 |

| 22 | 0.025 | 0.644 | 0.030 | 0.759 | 0.028 | 0.711 | 0.031 | 0.794 | 0.034 0.853 | 22 |

| 24 | 0.020 | 0.511 | 0.024 | 0.607 | 0.022 | 0.559 | 0.025 | 0.635 | 0.028 0.701 | 24 |

| 26 | 0.016 | 0.405 | 0.018 | 0.455 | 0.018 | 0.457 | 0.019 | 0.476 | 0.022 0.551 | 26 |

| 28 | 0.013 | 0.321 | 0.015 | 0.378 | 0.014 | 0.356 | 0.016 | 0.397 | 0.019 0.475 | 28 |

| 30 | 0.010 | 0.255 | 0.012 | 0.305 | 0.012 | 0.305 | 0.013 | 0.318 | 0.016 0.399 | 30 |

3.How to Use the Gauge Chart for Selection

The so-called “sheet metal gauge chart” is not simply a list of references; it is a real guide to choosing the proper metal for a certain project. The ability to read and use this type of chart depends on how one comprehends the concept of gauge, thickness and material type. Thus, understanding it enables one to make correct decisions that enhance the quality of works produced and the time used in production.

To use the “sheet metal gauge chart” first, determine the metal material in question because different metals have different thickness measurements. Regardless of whether it is copper, aluminium, stainless steel or galvanised material, each material has its own specific characteristics for its application. For instance, the copper gauge chart may be used perfectly in situations where electrical conductivity is of the essence, such as wiring and plumbing services. On the other hand, the “aluminium gauge chart” will be most suitable for applications that require lightweight aluminium products, such as the car industry and the airline industry.

Subsequent to determining the type of glass, the next aspect is the choice of thickness of glass needed for the particular project. This means that when it comes to gauge and thickness, there is a direct or inverse relationship between them. For instance, the “stainless steel gauge chart” allows choosing a smaller number – meaning a greater thickness – for sheets that will be used in, for example, kitchen tops or industrial tools and parts. On the other hand, a higher gauge number may be selected for thinner and decorative or lighter products.

The last of these is the state of the environment under which the material is to be used in the construction industry. For any project that needs the steel to be rust resistant, then the “galvanised steel gauge chart” would come in handy. For instance, when constructing sites that are exposed to regular outside conditions, a lower gauge number might be chosen for a thicker galvanised steel so as to accommodate the outside conditions.

One of the most important tools that were observed to make the task easier to complete is the “sheet metal gauge chart”, which ensures that there isn’t a lot of guesswork when it comes to choosing the material thickness. Thus, by interpreting the described chart, professionals can ensure that they select the proper material to improve the performance and durability of the project significantly.

4.Sheet Metal Gauge Charts

The so-called “sheet metal gauge chart” is a reference chart that presents the specific thickness of different materials such as copper, aluminium, stainless steel, and galvanised steel. There are individual charts for each type of material, depending on their characteristics and uses.

The “copper gauge chart” is the shop standard in electrical and plumbing industries because copper’s thickness determines its conductivity and resistance to corrosion. For example, to venture into strenuous activities, a thick copper, which can be referred to as a low number gauge, is the most appropriate,e as a thin copper is best suited for lighter activities and can be referred to as a high number gauge.

Aluminum is a material of choice in applications where weight reduction is a factor, and hence, one must use the aluminium gauge chart. Due to its relatively low density, aluminium is widely used in car manufacturing and aeroplanes, and the chart illustrates how thin or thick aluminium should be for best performance and safety.

Likewise, the stainless steel gauge chart is commonly used where there is a need for a high level of corrosion or durability. For a wide range of applications, starting with kitchen appliances and moving on to medical device production, such as stainless steel, the chart helps to choose the right thickness.

Finally, there is the “galvanised steel gauge chart”. This product is very crucial in construction and outside projects. Rust resistance is evident from the galvanised coating, and the chart shows detailed measures of thickness for this environment. For instance, a lower gauge number could be used for roofing sheets to warrant them suitable for rain and wind.

So, it could be said that the ‘sheet metal gauge chart’ is an all-purpose and essential document. It avoids the use of incorrect material as it affords clear and straightforward measurement, thereby increasing quality and work productivity.

| Gauge | Carbon Steel | Galvanized Steel |

Stainless Steel |

Copper | Brass |

| 7 | 0.1793 | 0.1443 | 0.0179 | 0.18 | 0.1443 |

| 8 | 0.1644 | 0.1285 | 0.17187 | 0.165 | 0.1285 |

| 9 | 0.1495 | 0.1144 | 0.15625 | 0.148 | 0.1144 |

| 10 | 0.1345 | 0.1019 | 0.14062 | 0.134 | 0.1019 |

| 11 | 0.1196 | 0.0907 | 0.125 | 0.12 | 0.0974 |

| 12 | 0.1046 | 0.0808 | 0.10937 | 0.109 | 0.08081 |

| 14 | 0.0747 | 0.0604 | 0.07812 | 0.083 | 0.06408 |

| 16 | 0.0598 | 0.0508 | 0.0625 | 0.065 | 0.05062 |

| 18 | 0.0478 | 0.0403 | 0.05 | 0.049 | 0.0403 |

| 20 | 0.0359 | 0.0319 | 0.0375 | 0.035 | 0.03196 |

| 22 | 0.0299 | 0.0253 | 0.03125 | 0.028 | 0.02535 |

| 24 | 0.0239 | 0.0201 | 0.025 | 0.022 | 0.0201 |

| 26 | 0.0179 | 0.0159 | 0.01875 | 0.018 | 0.01594 |

| 28 | 0.0149 | 0.0126 | 0.01562 | 0.014 | 0.01264 |

Conclusion

Knowledge and application of the “sheet metal gauge chart” go hand in hand with professionals regardless of their speciality.

Using this tool will make it easy for the project manager or any field engineer to know the right choice between the copper gauge chart, the aluminium gauge chart, the stainless steel gauge chart or the galvanised steel gauge chart, depending on the thickness required for the application.

A gauge thickness chart helps in determining how to make appropriate choices by having an understanding of how the two interact and applying a glimpse of the chart to make appropriate and ideal decisions regarding the quality and durability of projects.

In electrical wiring right through to the construction of the outdoors, the “sheet metal gauge chart” is an ally that guarantees timely triumph in all pursuits.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024