Square Tube Size: Which You Should Know

Introduction

Square tubes are essential structural components widely utilized in construction, fabrication, and industry. Square tubes come in various sizes, thicknesses, and materials and provide strength, toughness, and elasticity for recycling.

Careful selection of the size of the square tube is necessary in order to provide maximum load-carrying capacity and structural integrity.

For framing equipment in buildings or specialty fabrications, knowledge of general known sizes and material characteristics will help in making the most suitable selection.

This guide covers the general size of square tube, its application, and some points to choose a better size for your construction needs and structural design for strength and economy.

1. What is the square tube?

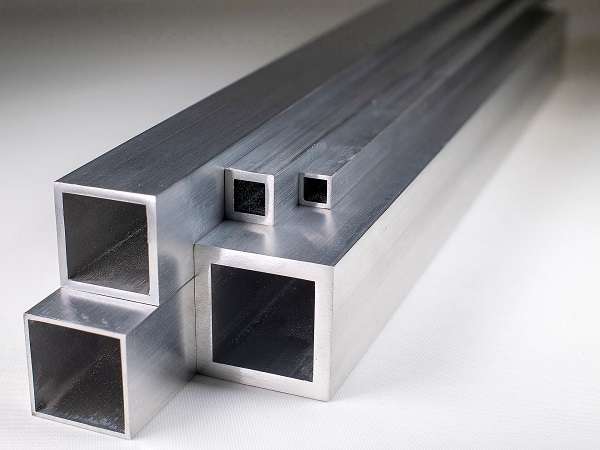

A square tube is an empty four-sided strength unit mainly deployed in construction, manufacturing, and industry. It is designed to be strong, stable, and durable and deployed to frameworks, support structures, and special fabrications.

Square tubes are available in different sizes of square tube with different widths, wall thicknesses, and materials like steel, aluminum, and stainless steel.

There are also perforated square tubes, which are used in adjustable shelves, modular units, and fixing. They are hollow tubes that offer increased flexibility by offering easy bracket, bolt, and other hardware mounting.

The size of the square tubes while making the appropriate selections of tubing for load-carrying applications, which offers the best performance and life.

Light structures make use of smaller dimensions, whereas heavy-duty structures make use of thicker and larger pipes to ensure more durability. Square tubes are used extensively in construction frames, furniture production, and even car engineering.

From machine support and structural support to DIY purposes, the proper use of the correct square tube ensures effectiveness and longevity.

Material, thickness, and perforation need to be taken into account, users can find the most appropriate square tube for their respective applications.

2. What materials are used for the square tube?

Square tubes are constructed using different materials with varying properties for specific use. Selection of the material is based on strength, weight, corrosion, and usage. The following are the most prevalent materials used to construct square tubes:

· Steel Square Tubes:

They are used mostly because of their strength, hardness, and load-bearing ability. They are available to buy in carbon steel, galvanized steel, and stainless steel, thus best suited for building, heavy machines, and manufacturing.

· Aluminum Square Tubes:

Aluminum is lightweight and provides superior corrosion resistance. It finds widespread application in the aerospace, marine, automotive, and architectural fields.

Aluminum square tubes are very strong and lightweight compared to steel, thus most suitable for projects where weight reduction is of primary importance.

· Stainless Steel Square Tubes:

These are rust- and corrosion-resistant tubes, which are ideal for application in food processing, medical equipment, outdoor structures, and marine conditions. They also provide a shiny, polished appearance for ornamentation.

· Brass and Copper Square Tubes:

Less in demand but valued for their visual appeal and resistance to corrosion, brass and copper tubes are primarily used in decorative applications, plumbing, and electrical appliances.

Their unique characteristics render them most suitable for specialty applications.

With the right selection of material in terms of strength, longevity, and surrounding conditions, square tubes can effectively meet the demands of various structural, industrial, and decorative applications.

3. What is the application of the square tube?

Square tubes are extensively applied in many industries because of their strength, durability, and versatility. Their hollow nature offers great support without weight, hence, they can be utilized for a variety of applications, such as:

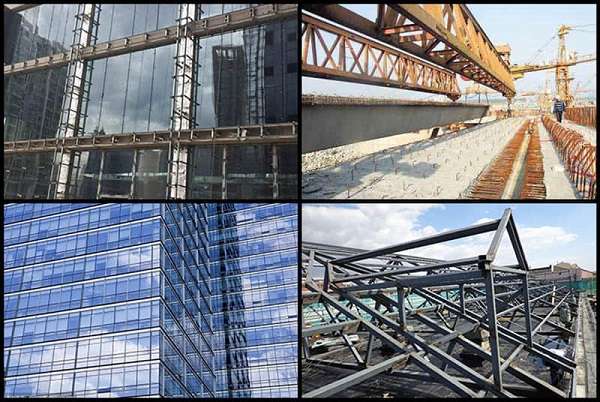

· Construction and Structural Support:

Square tubes are utilized daily in buildings, bridges, and pillars. They have a high strength-to-weight ratio, hence, they are a critical part of load-bearing frames and foundation support.

· Fabrication and Manufacturing:

Square tubes are applied to machine frames, conveyor systems, and metal fabrications in manufacturing. The linear shape and weldability of tubes enable accurate engineering applications in manufacturing industries.

· Interior Decoration and Furniture:

Contemporary furniture design extensively integrates square tubing in frames, legs of tables, shelves, and ornamental constructions. Aluminum and stainless steel tubes are particularly in demand because they give a cool look and long-lasting durability.

· Automotive and Transportation:

Square tubes are employed in automobile chassis, roll cages, trailers, and bicycle frames because of their shock resistance and strength. Lightweight aluminum tubes reduce the weight of the vehicle without compromising its structural integrity.

· Railings and Fencing:

Square tubes are normally utilized in gates, handrails, and security fences because of their stability and how easily they are installed. Stainless and galvanized steel types are lasting rust and corrosion shields.

· Equipment and Agricultural Equipment:

Square tubing is found in heavy equipment components, farm equipment, and storage racks, and it is a great support for rigorous conditions.

Most adaptable in use, square tubes are integral parts in construction, manufacturing, and design sectors.

| Square Tube Size | |||||||||

| Size (mm) |

Wal thickness (mm) |

Size (mm) |

Wal thickness (mm) |

Size (mm) |

Wal thicknoss (mm) |

Sze (mm) |

Wall thickness (mm) |

Sze (mm) |

Wall thickness (mm) |

| 20x10 | 0.7-2.0 | 70x25 | 12-60 | 10090 | 2.0-6.0 | 130x50 | 2.0-6.0 | 150x110 | 2.0-6.0 |

| 20x14 | 0.7-20 | 70x30 | 126.0 | 11025 | 20-6.0 | 130x60 | 20-6.0 | 150250 | 3.0-12.0 |

| 20x15 | 0.7-2.0 | 70x40 | 12-60 | 110x30 | 20-6.0 | 130x70 | 20-60 | 150300 | 3.0-12.0 |

| 26x13 | 07-2.0 | 70x50 | 2.0-6.0 | 11040 | 2.06.0 | 130x80 | 2.0-6.0 | 160x40 | 20-6.0 |

| 30x10 | 0.7-2.0 | 70060 | 20-6.0 | 110x50 | 20-6.0 | 130×90 | 206.0 | 16050 | 20-6.0 |

| 30x15 | 0.7-20 | 80x20 | 12-4.0 | 110660 | 20-6.0 | 130x100 | 206.0 | 16060 | 20-6.0 |

| 30:20 | 0820 | 80x25 | 12-60 | 110870 | 2.06.0 | 130x110 | 20-60 | 160x70 | 20-60 |

| 40x10 | 0.8-2.0 | 80x30 | 1.2-6.0 | 110x80 | 2.0-6.0 | 130x120 | 2.06.0 | 16090 | 2.0-6.0 |

| 40x15 | 1.0-2.0 | 80x40 | 126.0 | 110x90 | 20-6.0 | 140x30 | 206.0 | 16090 | 20-6.0 |

| 40:20 | 10-2.5 | 80x50 | 2.0-6.0 | 110x100 | 2.0-6.0 | 140x40 | 20-60 | 160x100 | 20-6.0 |

| 40-25 | 1.02.5 | 30860 | 2.06.0 | 110x140 | 4.06.0 | 140x50 | 2.0-6.0 | 180x40 | 2.0-6.0 |

| 40-30 | 10-2.5 | 80x70 | 2.0-6.0 | 12025 | 2.0-6.0 | 140x60 | 2.0-60 | 18050 | 20-6.0 |

| 50x11 | 1.02.0 | 90x25 | 1.2-6.0 | 120.30 | 2.06.0 | 140x70 | 2.06.0 | 18060 | 2.0-6.0 |

| 50x15 | 1.0-3.0 | 90x30 | 126.0 | 120840 | 206.0 | 140x80 | 2.06.0 | 180x70 | 206.0 |

| 50-20 | 1.0-3.0 | 90x40 | 2.0-6.0 | 120.50 | 2.060 | 14090 | 2.06.0 | 18080 | 20-6.0 |

| 50-25 | 1.0-3.0 | 90850 | 2.0-6.0 | 120x60 | 20-6.0 | 140x100 | 2.0-60 | 190040 | 2.0-6.0 |

| 50:30 | 1.0-3.0 | 90x60 | 20-6.0 | 120x70 | 20-6.0 | 140x110 | 206.0 | 190850 | 20-6.0 |

| 50x40 | 103.0 | 90x70 | 2.0-60 | 1207BO | 206.0 | 140x120 | 2.060 | 19060 | 20-6.0 |

| 60x15 | 10-3.0 | 90x80 | 2.0-60 | 120x90 | 2.0-6.0 | 150x30 | 20-60 | 190x70 | 20-6.0 |

| 60-20 | 1.0-3.0 | 10025 | 20-6.0 | 120x100 | 2.06.0 | 160x40 | 2060 | 200840 | 20-60 |

| 60-25 | 1.04.0 | 10030 | 2.0-6.0 | 120-110 | 2.0-8.0 | 150x50 | 2.06.0 | 200.50 | 2.0-6.0 |

| 60:30 | 10-4.0 | 10040 | 2.0-6.0 | 120x130 | 4.0-6.0 | 150x650 | 2.0-6.0 | 200060 | 2.0-6.0 |

| 60:40 | 1.26.0 | 10050 | 20-6.0 | 120x140 | 4.0-6.0 | 150x70 | 206.0 | 200x100 | 25-6.0 |

| 60.50 | 1.26.0 | 100060 | 2.0-6.0 | 120200 | 4.0-6.0 | 150x00 | 2.0-6.0 | 200300 | 3.0-13.0 |

| 70020 | 10-6.0 | 100x70 | 2.0-6.0 | 130830 | 2.0-6.0 | 150x90 | 2.0-6.0 | 200x400 | 3.0-13.0 |

| 70-25 | 126.0 | 10030 | 20-6.0 | 130840 | 206.0 | 150x100 | 206.0 | ||

4. How to choose the right square tube?

Choosing the right square tube is based on several factors, such as material, size, thickness, and use. The following is a guide to assist you in choosing the best option:

Choose the Application:

Decide where the square tube will be applied. For construction structural support, steel square tubes are suitable, while aluminum tubes are suitable for light applications such as furniture or automobile frames.

Choose the Proper Material:

- Steel(galvanized, stainless, or carbon) is ideal for heavy-duty and high-load use.

- Aluminum is corrosion-resistant and light, and it is used in the aerospace, marine, and architectural fields.

- Stainless Steel offers top rust resistance for outdoor or food-grade uses.

- Brass or copper is ideal for decorative or electrical uses.

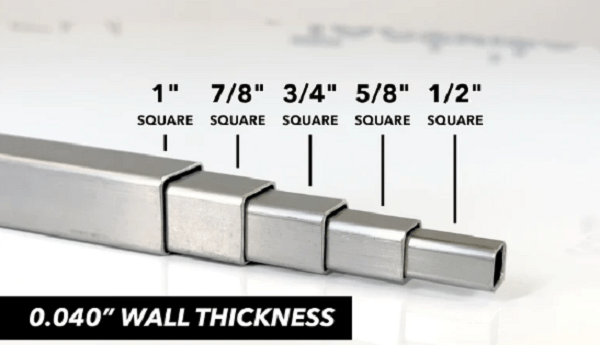

Choose the Correct Diameter and Wall Thickness:

Tube size and wall thickness must be relative to the strength and loading capacity one wishes to achieve. Stronger but heavier walls are thicker, while lighter walls should be used where light loads are involved.

Take into Consideration Corrosion Resistance:

Where the tube will be coming into contact with chemicals or water, use stainless steel, galvanized steel, or aluminum to avoid rusting and degradation.

Determine Cost and Availability:

Match your budget to the required performance. Steel is inexpensive for heavy-duty applications, while aluminum or stainless steel is more expensive but provides long-lasting durability.

Using these specifications, you can choose the right square tube that gives your project the strength, durability, and environmental versatility it needs.

Conclusion

Square tubes are integral structure elements that are utilized in the construction, manufacturing, furniture, automotive, and industrial sectors.

Square tubes come in different sizes, wall thicknesses, and materials and provide strength, durability, and flexibility for a variety of load-bearing applications.

Square tube selection is based on the type of material, application, wall thickness, and anti-corrosion. Steel square tubes possess incredibly huge strength for heavy construction, and the aluminum and stainless steel forms are light in weight and corrosion-resistant.

Knowing square tube dimensions guarantees perfect functionality, be it strengthening a structure, building machines, or making contemporary furniture design.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?

Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!