Discover the Teflon Piping Size Chart

Introduction

Discover the Teflon piping size chart, including detailed dimensions, inner and outer diameters, and wall thickness for various applications. Ideal for engineers, plumbers, and industrial professionals seeking precise specifications.

1. What is the Teflon piping?

The production of Teflon piping requires PTFE (Polytetrafluoroethylene) as the primary material component, which delivers high performance alongside resistance to chemicals and non-stick properties for industrial applications, particularly in the chemical processing, food production, and pharmaceutical sectors.

The material demonstrates outstanding performance against extreme heat and strong chemical agents, which makes it perfect for transporting harmful solutions.

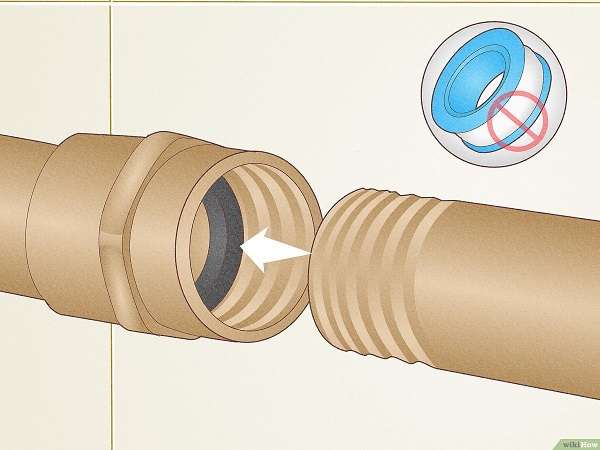

Teflon tape finds usage in sealing threaded Teflon piping joints because it forms a reliable and leak-proof connection.

A hypodermic tube serves as a medical and precision equipment thin-walled metal tube, but Teflon piping displays non-metallic characteristics and a high level of flexibility while functioning in industrial environments requiring demanding conditions.

The PTFE pipe specification includes real data about available sizes and maximum operating pressure, together with temperature constraints.

| Nominal diameter | Specificatiom of steel pipe T |

Raised face A |

PTFE pipe B |

Inside diameter D1 |

Holes diatance thickness t |

Outside distance of large flange D |

Holes distance of large flange K |

Thicknes S of large flange C |

|

| DN(mm) | NPSN(inch) | ||||||||

| 15 | 1/2 | 25*2.5 | 40 | 20 | 16 | 2.0 | 90 | 65 | 11 |

| 20 | 3/4 | 29*2.5 | 50 | 25 | 20 | 2.0 | 100 | 75 | 11 |

| 25 | 1 | 34*3 | 60 | 29 | 24 | 2.0 | 110 | 85 | 12 |

| 32 | 11/4 | 42*3 | 70 | 36.5 | 32 | 2.0 | 130 | 100 | 13 |

| 40 | 11/2 | 45*3 | 80 | 40 | 34 | 2.5 | 140 | 110 | 14 |

| 50 | 2 | 57*3.5 | 95 | 51 | 45 | 2.5 | 155 | 125 | 14 |

| 65 | 21/2 | 76*4 | 115 | 68 | 62 | 2.5 | 175 | 145 | 16 |

| 80 | 3 | 89*4 | 130 | 81.5 | 75 | 3.0 | 190 | 160 | 16 |

| 100 | 4 | 108*4 | 150 | 101 | 94 | 3.0 | 210 | 180 | 18 |

| 125 | 5 | 133*4.5 | 180 | 125.5 | 118 | 3.5 | 240 | 210 | 20 |

| 150 | 6 | 159*5 | 205 | 150 | 141 | 4.0 | 275 | 240 | 20 |

| 200 | B | 219*6.5 | 265 | 207 | 196 | 4.0 | 330 | 295 | 20 |

| 250 | 10 | 273*8 | 320 | 257 | 247 | 5.0 | 385 | 350 | 23 |

| 300 | 12 | 325*8 | 365 | 310 | 299 | 5.0 | 435 | 400 | 23 |

2. What materials are used for Teflon piping?

Teflon piping is primarily manufactured using PTFE (Polytetrafluoroethylene), a high-performance fluoropolymer known for its outstanding chemical resistance, non-stick surface, and ability to withstand extreme temperatures.

Other fluoropolymer materials and composites may also enhance performance depending on the application. Common materials include:

· PTFE (Polytetrafluoroethylene)

PTFE stands as the primary material choice for Teflon piping systems because it provides exceptional thermal endurance, together with chemical tolerance and minimal friction characteristics.

· FEP (Fluorinated Ethylene Propylene)

The melt-processable fluoropolymer FEP delivers great flexibility as well as transparency and chemical resistance through fabrication methods that are simpler than PTFE.

· PFA (Perfluoroalkoxy Alkane)

PTFE solutions in PFA (Perfluoroalkoxy Alkane) stand out as an optimal solution for difficult industrial uses because high temperature performance combines with strength and chemical resistance.

· Modified PTFE

The modification of PTFE leads to improved mechanical strength and lower permeability, along with reduced creep under loads.

· PTFE-Lined Metal Pipes

PTFE-Lined Metal Pipes represent a combination of metal structure strength with PTFE's corrosion resistance characteristics, which makes them suitable for high-pressure and industrial applications.

The material selection process chooses specific substances that match necessary criteria like maximum allowable pressure and minimum-maximum operational temperature, with resistance to chemicals, together with stainless steel strength.

3. What is the application of the Teflon piping?

Teflon piping consists mainly of PTFE components because of its superb chemical immunity and high heat endurance, and non-adhesive characteristics that suit challenging industrial needs.

Through its special characteristics, Teflon delivers dependable service within these particular sectors:

· Chemical Processing

The transportation of corrosive acids and solvents, and reactive chemicals uses chemical processing since it provides safe handling despite conditions that could degrade materials or cause contamination.

· Pharmaceutical & Biotechnology

The pharmaceutical and biotechnology industries utilize this tubing material to transfer fluids inside sterile rooms because it presents non-reactive properties and easy cleaning, as well as hygienic operating surfaces.

· Food and Beverage Industry

The food and beverage industry can use this material to move food ingredients and additives safely since it keeps their contents protected against build-up and contamination.

· Semiconductor Manufacturing

Ultraclean chemical delivery networks in semiconductor production rely on the essential semiconductor manufacturing materials.

· Oil & Gas Industry

The Oil & Gas sector applies methylene chloride piping for high-temperature and high-pressure fluid distribution across refineries and processing sites and pipelines.

· Water Treatment Plants

Water Treatment Plants depend on the material because it displays excellent resistance against scaling and fouling, along with resistance to harsh treatment chemicals, therefore working well as a long-term component in water purification systems.

· Aerospace & Automotive

The aerospace industry, together with the automotive field, relies on PTFE tubing for fuel lines and brake applications, and hydraulic system distribution because dependable performance under harsh conditions is essential.

Teflon piping serves industries that require high standards of safety because it 0demonstrates excellent durability alongside flexible character and extreme condition resistance.

4. How to choose the right Teflon piping?

The right choice of Teflon piping (PTFE piping) requires evaluation of essential factors that match your application requirements. The following guide will help you select the right Teflon piping according to your needs.

· Understand the Application Requirements

Research the material properties based on the pipe contents (food or chemicals or gases, and more), as well as operating temperature ranges and maximum allowed pressure. PTFE pipes work well under corrosive and high-temperature situations, yet require reinforced or lined systems when added strength is needed.

· Review PTFE Pipe Specifications

- Examine key parameters such as:

- Inner and outer diameter

- Wall thickness

- Working pressure and temperature limits

- Flexibility and tensile strength

The specifications need to match your system to guarantee compatibility, along with system efficiency.

· Ensure Chemical Compatibility

PTFE shows strong resistance to many harsh chemicals, although testing your particular media is necessary to guarantee no deterioration leading to failure during the product's lifespan.

· Check Temperature and Pressure Ratings

Test the pipe to verify it can survive all operational maximum conditions of your system. Standard PTFE pipes function within -200°C to +260°C temperature ranges, while their pressure tolerance depends on the piping dimensions and design configuration.

· Choose the Correct Fittings and Sealing Method

Determine the connection method for piping, which can include threaded or flanged, or welded elements. To create leak-proof threaded connections along with safe connections, Teflon tape serves as the standard sealing material.

· Compliance with Industry Standards

Piping systems used in pharmaceuticals and food processing, or medical sectors, should obtain FDA and USP Class VI and appropriate safety and hygiene standards certifications.

· Select the Most Suitable Material Variant

PTFE stands as the primary choice for Teflon piping since it demonstrates exceptional chemical resistance, together with heat tolerance, and other alternatives, including FEP, PFA, and modified PTFE, serve different applications with specific advantages.

FEP delivers excellent visualization during flow checking, yet PFA proves stronger and operates at higher temperatures, and modified PTFE offers better surface finish, together with lower permeability.

Selection of suitable materials requires chemical analysis combined with temperature demands and mechanical requirements, and all governing regulations. Detailed expert review of PTFE pipe requirements produces dependable solutions that succeed in enduring over extensive periods.

Conclusion

The Teflon piping size chart serves as a crucial reference for selecting the right pipe dimensions to suit your specific application.

Based on the above considerations—such as PTFE pipe specifications, chemical compatibility, temperature and pressure ratings, and installation requirements—the chart helps match the correct size and type of Teflon piping to your system needs.

Whether you’re working with aggressive chemicals, high-temperature environments, or hygienic industries, using the proper size ensures safety, durability, and efficiency. Combined with the correct use of Teflon tape and fittings, the size chart simplifies decision-making and supports long-term, reliable piping performance.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024